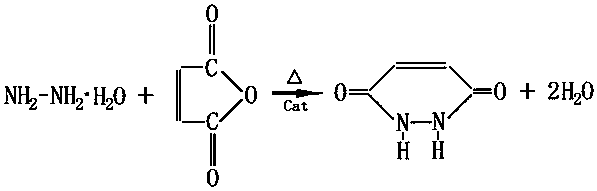

Synthetic method of maleic hydrazide

A technology of maleic hydrazide and its synthesis method, which is applied in the field of maleic hydrazide synthesis, can solve the problems of large waste discharge, difficult wastewater treatment, high treatment cost, etc., achieve less waste discharge, good catalytic effect, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] 200g of maleic anhydride, 250g of hydrazine hydrate with a content of 80%, and 20g of sodium 2,6-dimethylphenylborate are placed in a four-necked flask with stirring, a thermometer and a rectifying column, and the stirring is started, and the temperature is raised to Reflux, when the steam enters the rectification column, extract water vapor at the column top temperature of 95 ° C ~ 100 ° C, react at the reflux temperature for 4 to 6 hours, and end the reaction when no condensed water flows out from the top of the rectification column, and use vacuum distillation Evaporate all the remaining hydrazine hydrate in the flask, then cool the flask to normal temperature, add an appropriate amount of pure water, start stirring, when the solid matter in the flask is stirred into a slurry, put it into a centrifugal filter to filter, and then use an appropriate amount of pure water The filter cake was washed with water, and the washed filter cake was centrifugally dehydrated and dr...

Embodiment 2

[0013] Put 200 g of maleic anhydride, 280 g of hydrazine hydrate with a content of 90%, and 30 g of sodium 2,6-dimethylphenylborate in a four-necked flask with stirring, a thermometer and a rectifying column, start stirring, and heat up to Reflux, when the steam enters the rectification column, extract water vapor at the column top temperature of 95 ° C ~ 100 ° C, react at the reflux temperature for 4 to 6 hours, and end the reaction when no condensed water flows out from the top of the rectification column, and use vacuum distillation Evaporate all the remaining hydrazine hydrate in the flask, then cool the flask to normal temperature, add an appropriate amount of pure water, start stirring, when the solid matter in the flask is stirred into a slurry, put it into a centrifugal filter to filter, and then use an appropriate amount of pure water The filter cake was washed with water, and the washed filter cake was centrifugally dehydrated and dried to obtain 220.7 g of maleic hyd...

Embodiment 3

[0015] Put 200g of maleic anhydride, 300g of hydrazine hydrate with a content of 99%, and 40g of sodium 2,6-dimethylphenylborate in a four-necked flask with stirring, a thermometer and a rectifying column, start stirring, and heat up to Reflux, when the steam enters the rectification column, extract water vapor at the column top temperature of 95 ° C ~ 100 ° C, react at the reflux temperature for 4 to 6 hours, and end the reaction when no condensed water flows out from the top of the rectification column, and use vacuum distillation Evaporate all the remaining hydrazine hydrate in the flask, then cool the flask to normal temperature, add an appropriate amount of pure water, start stirring, when the solid matter in the flask is stirred into a slurry, put it into a centrifugal filter to filter, and then use an appropriate amount of pure water The filter cake was washed with water, and the washed filter cake was centrifugally dehydrated and dried to obtain 223.5 g of maleic hydraz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com