Epoxy resin conductive adhesive film and preparation method thereof

A technology of epoxy resin and conductive adhesive film, used in conductive adhesives, adhesives, film/sheet adhesives, etc. , low oxidation resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a kind of preparation method of epoxy resin conductive glue film, comprises the following steps:

[0054] In terms of mass fraction, mix 30-50% of silver-plated copper powder, 2-4% of ion scavenger, and 20-30% of epoxy resin in a solvent, and add 25-35% of butane with active groups. Nitrile rubber and 1-3% curing agent to obtain epoxy resin conductive adhesive paste;

[0055] coating the epoxy resin conductive adhesive paste on the base film, and baking to remove the solvent to obtain the epoxy resin conductive adhesive film.

[0056] In the preparation method of the present invention, the types and amounts of the preparation raw materials involved are consistent with the types and amounts of the corresponding raw materials above, and will not be repeated here.

[0057] In the present invention, the baking temperature is preferably 110-130° C., more preferably 115-125° C.; the baking time is preferably 2-3 minutes.

[0058] The inve...

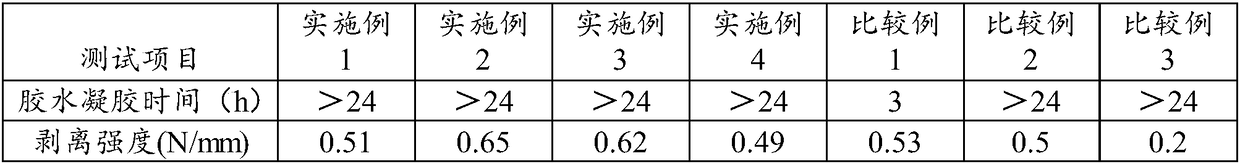

Embodiment 1

[0065] Add 43 parts of flaky silver-plated copper powder, 3 parts of ion scavenger IXE-100, 25 parts of epoxy resin GESR901, add an appropriate amount of solvent and mix well, then add 28 parts of carboxylated nitrile rubber 1072CG, curing agent 4,4' 1 part of diaminodiphenyl sulfone, stirred evenly to prepare conductive adhesive paste. Then, the slurry is coated on the base film by a coating machine, the solvent is removed by baking, and then the conductive adhesive film is obtained.

[0066] The thickness of the conductive adhesive layer in the prepared conductive adhesive film was 10 μm, the thickness of the release film in the base film was 50 μm, the thickness of the black ink layer was 10 μm, and the thickness of the copper layer was 200 μm.

Embodiment 2

[0068] According to the ratio of raw materials in Table 1, the conductive adhesive film was prepared by the preparation method in Example 1.

[0069] The thickness of the conductive adhesive layer in the prepared conductive adhesive film was 10 μm, the thickness of the release film in the base film was 70 μm, the thickness of the black ink layer was 8 μm, and the thickness of the copper layer was 200 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com