Distributed solar heat storage device

A heat storage device and heat storage technology, applied in the field of solar energy utilization, can solve the problems of increased investment cost, scale formation, low cost, etc., and achieve the effects of rapid cost reduction, small heat collection area, and rapid output increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

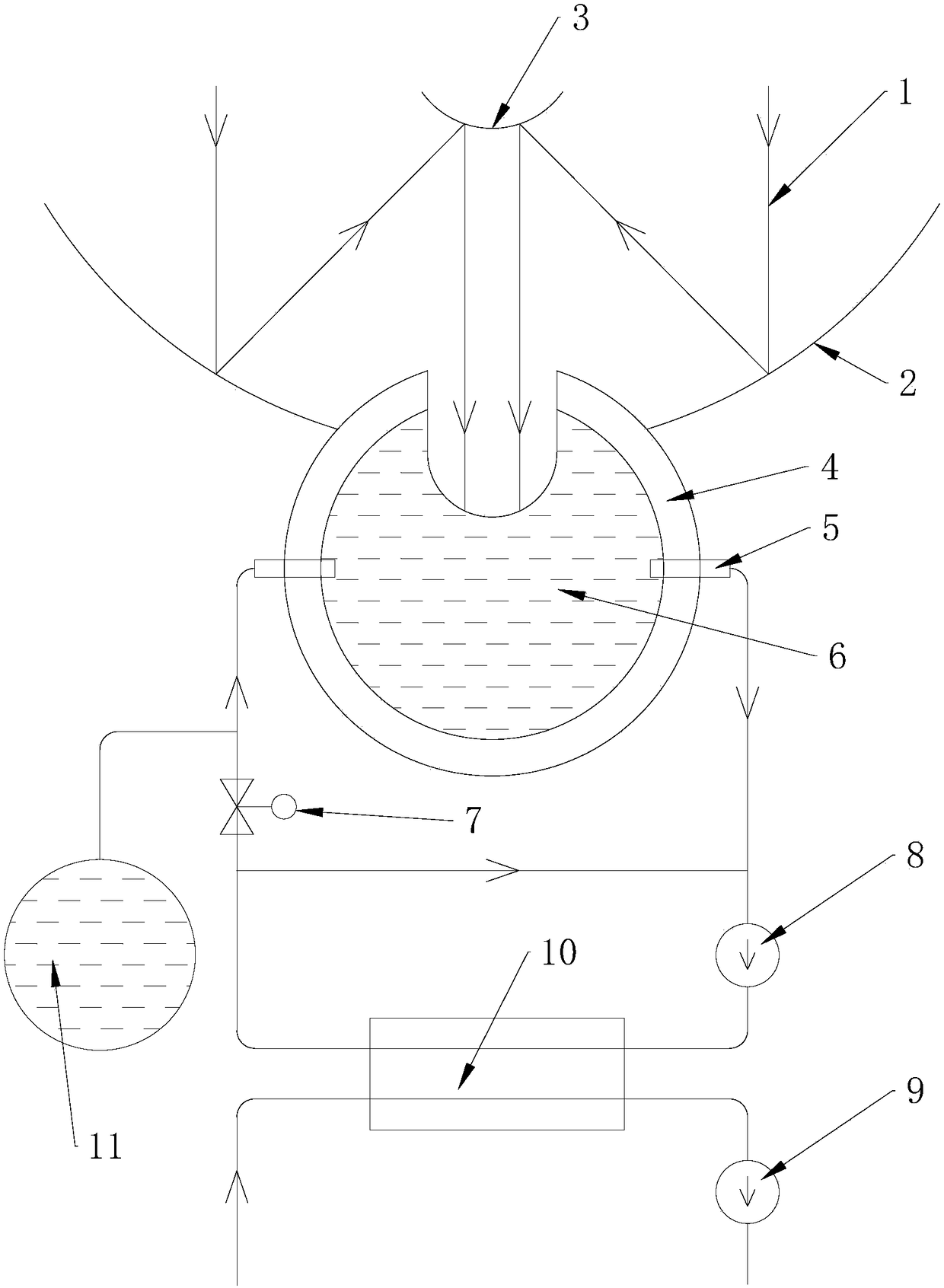

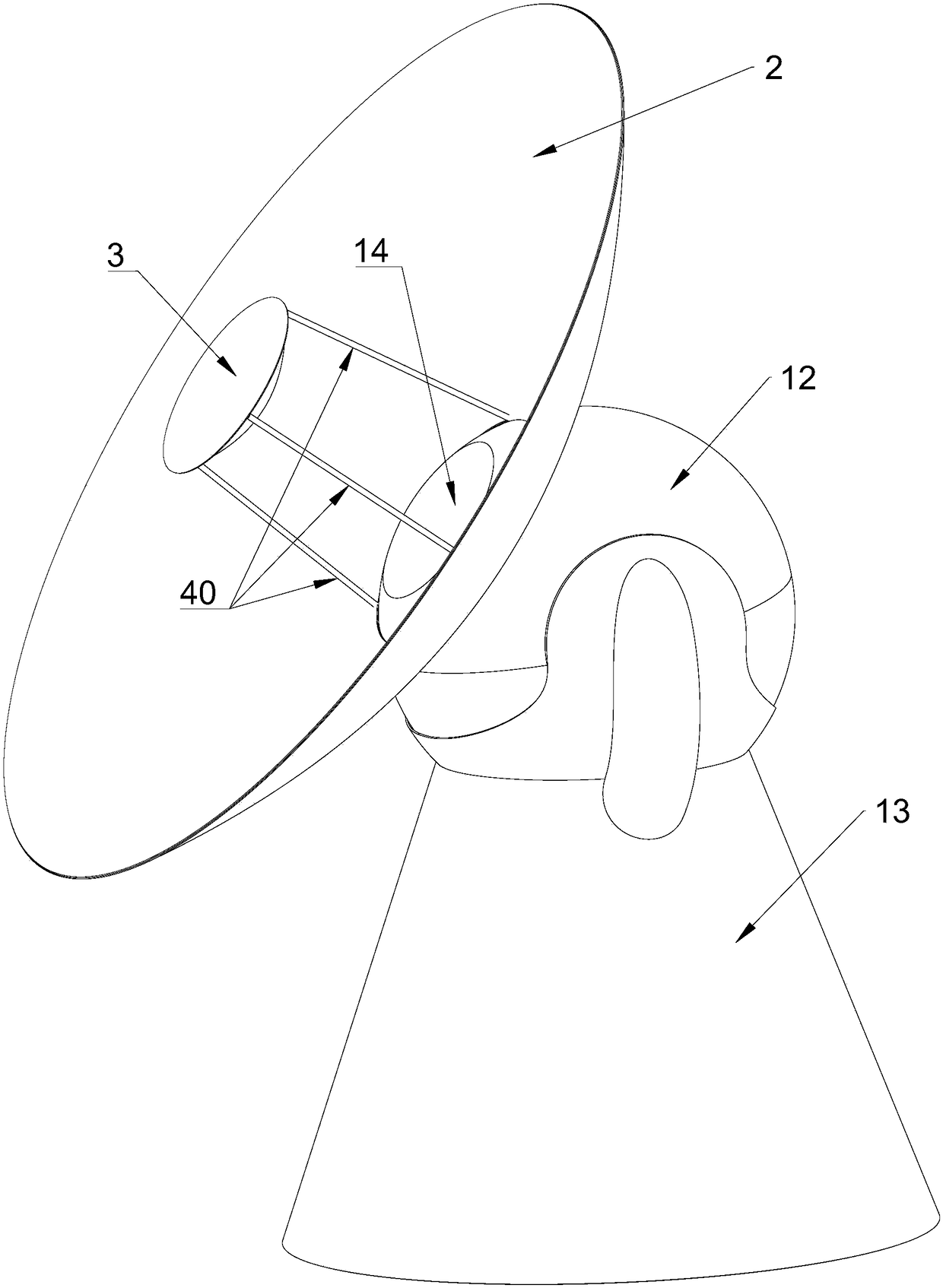

[0080] like figure 1 , 3 -8, the present embodiment consists of a light concentrating device, a heat storage container 12, a regulating valve 7, an oil pump 8, a water pump 9, a heat exchanger 10, an expansion tank 11, a cloud platform 18, a lower frame 21, and a support stand 22 , Pitch transmission mechanism and horizontal transmission mechanism;

[0081] The light collecting device comprises a large reflector 2, a small reflector 3 and a pole 40, and the small reflector 3 is connected to the large reflector 2 through the pole 40; The electronic module composed of electronic gyroscope measures the azimuth angle of the concentrating device;

[0082] The light concentrating device is installed on the heat storage container 12; the heat storage container 12 is composed of an outer shell 23, an insulation layer 4, a heat storage container liner 25, a tempered glass 14 and a vacuum glass 24; the heater 26 is installed on the heat storage container liner 25 Above, the two form ...

Embodiment 2

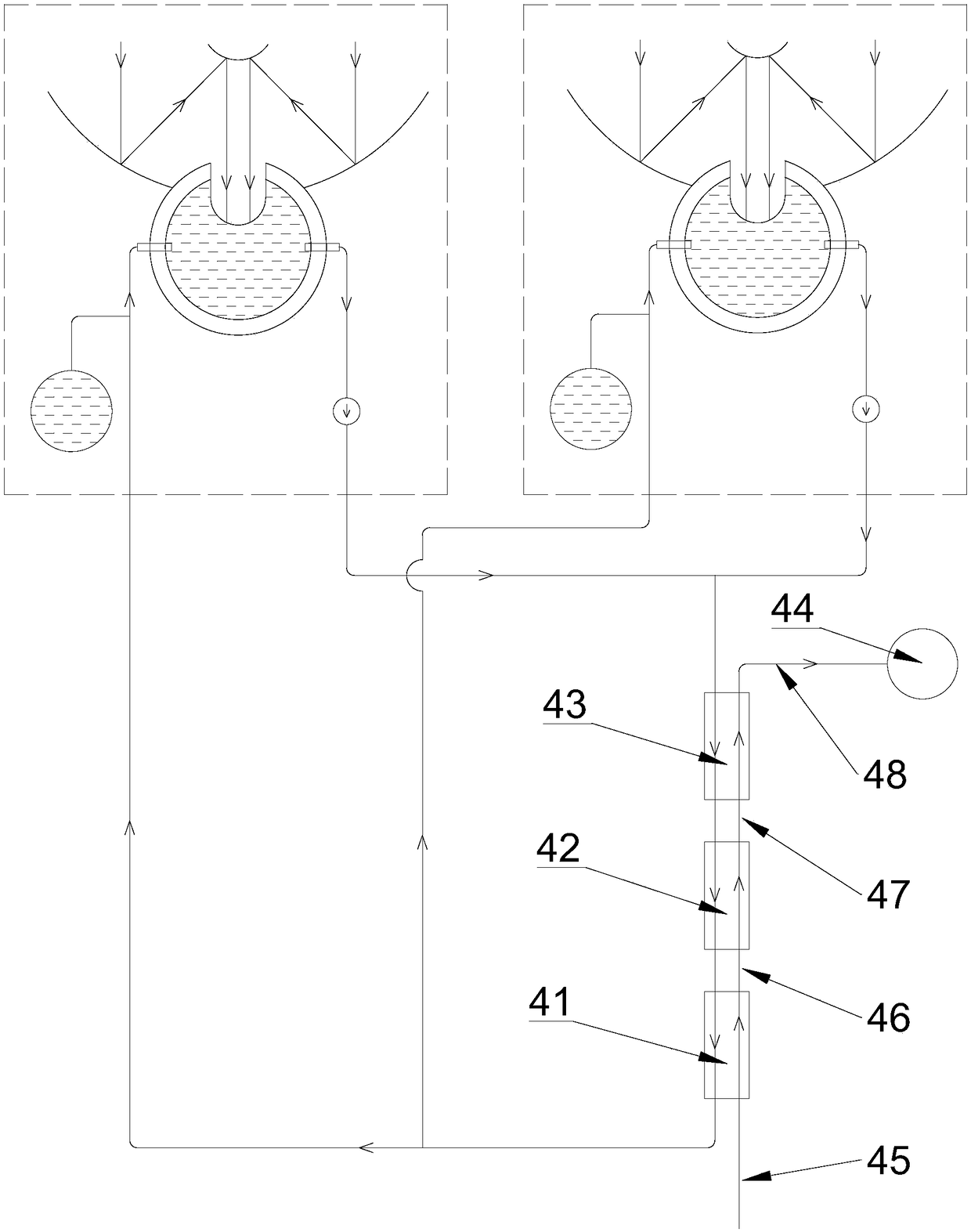

[0099] like Figure 2-6 , 8, and 9, the present embodiment is made up of light concentrating device, heat storage container 12, oil pump 8, expansion tank 11, cloud platform 18, lower frame 21, support stand 22, pitch transmission mechanism and horizontal transmission mechanism;

[0100] The light collecting device comprises a large mirror 2, a small mirror 3 and a pole 40, and the small mirror 3 is connected to the large mirror 2 through the pole 40; the back of the small mirror 3 is equipped with an electronic compass, a biaxial tilt sensor and An electronic module composed of electronic gyroscopes is used to measure the azimuth angle of the light-gathering device;

[0101] The light concentrating device is installed on the heat storage container 12; the heat storage container 12 is composed of an outer shell 23, an insulation layer 4, a heat storage container liner 25, a tempered glass 14 and a vacuum glass 24; the heater 26 is installed on the heat storage container liner ...

Embodiment 3

[0117] This embodiment is a design method using a vacuum insulation structure as the insulation layer 4 .

[0118] like figure 1 , 3 , 4, 6-8, and 10 show that the present embodiment consists of light concentrating device, heat storage container 12, regulating valve 7, oil pump 8, water pump 9, heat exchanger 10, expansion tank 11, cloud platform 18, lower frame 21. Supporting platform 22, pitch transmission mechanism and horizontal transmission mechanism;

[0119] The light-gathering device comprises a large reflector 2, a small reflector 3 and a strut 40, and the small reflector 3 is connected to the large reflector 2 through the strut 40;

[0120] The light concentrating device is installed on the heat storage container 12; the heat storage container 12 is made up of the shell 23, the heat storage container liner 25, the vacuum pressure-bearing shell 50, the tempered glass 14, the Dewar bottle 49 and the bearing member 55; the heater 26 and The load-bearing member 55 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com