Accelerated test and prediction method for service life of laser optical component

A technology of optical components and testing methods, which is applied in the direction of testing optical performance, measuring devices, scientific instruments, etc., can solve problems such as the inability to directly apply the reliability evaluation of optical systems, the inability to obtain the service life of components, and the high cost of testing, so as to achieve high confidence Accuracy and practicability, high test efficiency, simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

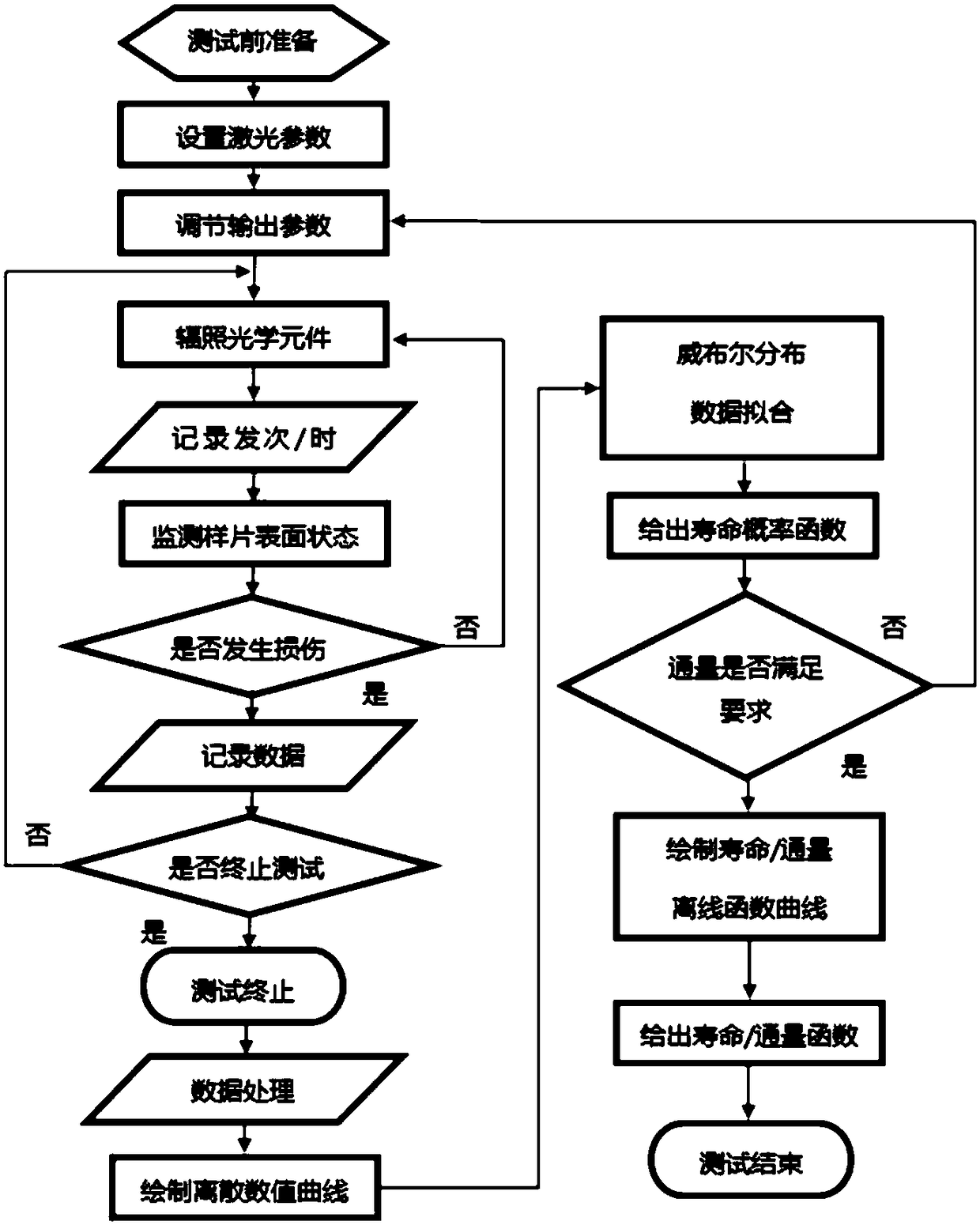

Method used

Image

Examples

Embodiment 1

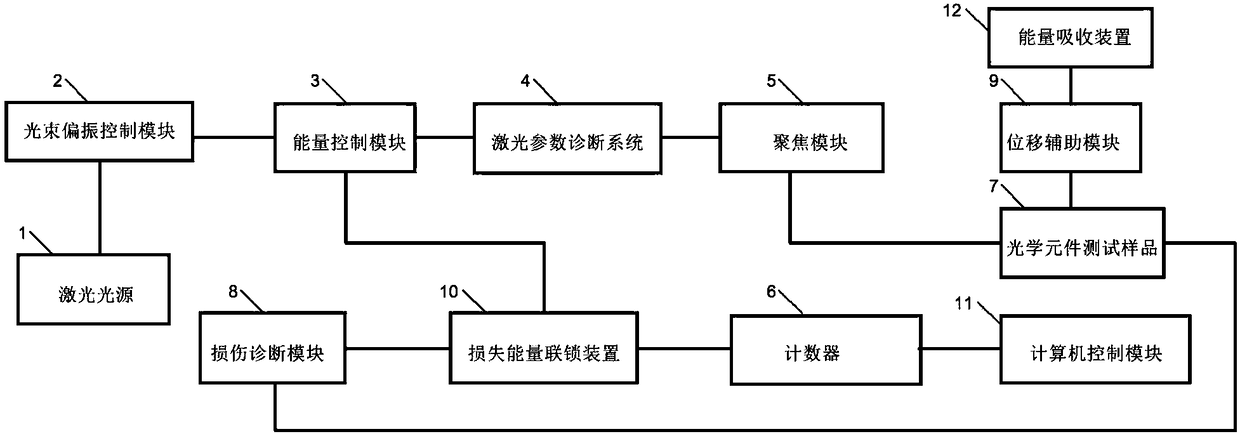

[0081] The schematic diagram of the life accelerated test system in the present invention refers to the appended figure 2 , including a laser light source 1 processing emission module and an optical element test sample 7, a counter 6, a damage diagnosis module 8, a displacement auxiliary module 9, a damage energy interlocking device 10, an energy control module 3, a computer control module 11 and an energy absorption device 12, The optical element test sample 7 is arranged on the displacement auxiliary module 9; the displacement auxiliary module 9 adjusts the position of the optical element test sample 7;

[0082] The laser light source 1 processes the emission module, and emits laser light with specific laser parameters to irradiate the optical element test sample 7;

[0083] The damage diagnosis module 8 detects the damage degree of the optical element test sample 7, and sends out a damage signal when it detects that the optical element test sample 7 is irreversibly damaged...

Embodiment 2

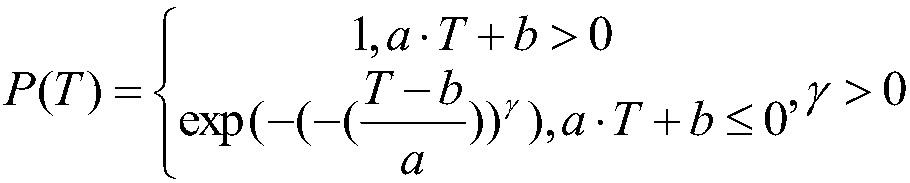

[0130] On the basis of Example 1, the lifetime flux function under a specific lifetime probability is obtained;

[0131] Substituting the expected laser flux into the lifetime flux function to obtain the estimated service life under the expected laser flux and specific lifetime probability;

[0132] In the case of not specifying the life probability, calculate the life corresponding to the maximum life probability and the minimum life probability under a specific flux, and obtain the expected result of the service life range under a specific flux.

[0133] The life cycle or time of the present invention is not the damage threshold or damage growth factor under the action of finite laser pulses or time, the test results are more in line with the actual use requirements of laser devices, and the test results can be directly applied to the reliability analysis of optical systems, and can be The service life of optical components under any flux is predicted, and the test efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com