Photosensitive resin solution and photosensitive dry film of circuit board and preparation methods

A technology of gum resin and circuit board, which is applied in the field of photosensitive resin glue, photosensitive dry film and preparation of circuit board, can solve the problems of affecting the imaging quality of photosensitive dry film, increasing the amount of product scrapping, and slow photosensitive speed, etc., to achieve Fast photosensitive speed, low cost, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

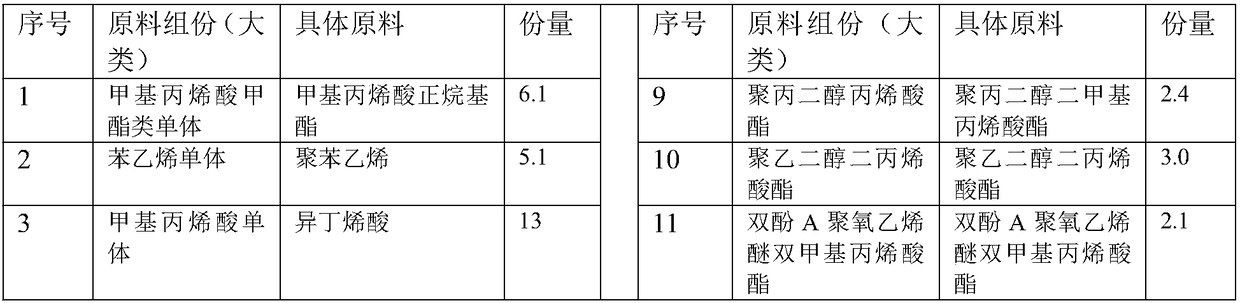

[0042] The chemical composition of the circuit board photosensitive adhesive resin glue of the first embodiment of table 1

[0043]

[0044]

[0045] Based on the materials in Table 1, the preparation method of the first circuit board photosensitive adhesive resin glue is as follows:

[0046] (1) Raw glue preparation: 1.5 parts of ethyl p-dimethylaminobenzoate (EDB), 6.1 parts of n-alkyl methacrylate, 5.1 parts of polystyrene, 13 parts of methacrylic acid, 3 parts of 2-butyl acrylate Esters, 3.5 parts of 2,2'-azobisisobutyronitrile are fully mixed and 20 parts of methyl ethyl ketone are added to the reaction axe, and heated to 60 degrees Celsius, the chemical reaction starts, and evenly stirred for 48 hours to obtain the raw gum liquid;

[0047] (2) Photosensitive adhesive preparation: 1.3 parts of ethyl p-dimethylaminobenzoate (EDB), 3.3 parts of 4,4'-bis(diethylamino)benzophenone, 3.0 parts of ETPTA, 2.4 parts of polypropylene glycol dimethyl Base acrylate, 3.0 parts...

Embodiment 2

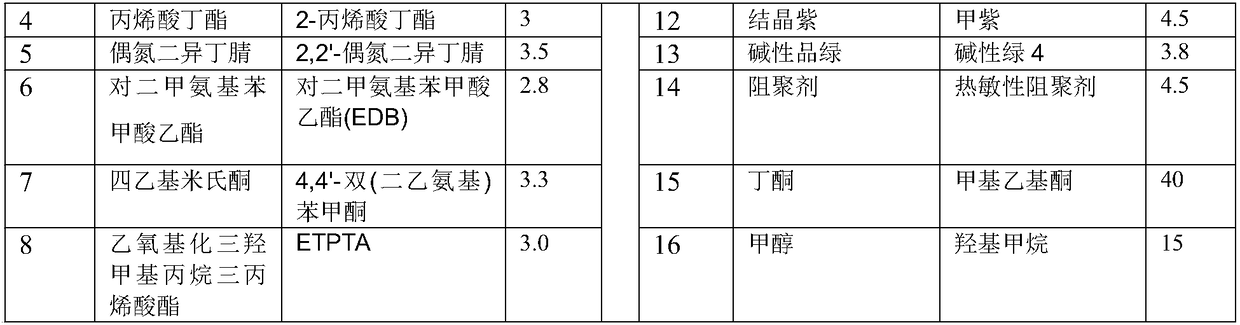

[0051] The chemical composition of the circuit board photosensitive adhesive resin glue of the 2nd embodiment of table 2

[0052]

[0053]

[0054] Based on the materials in Table 2, the preparation method of the second circuit board photosensitive adhesive resin glue is as follows:

[0055] (1) Preparation of the original glue solution: 1 part of ethyl p-dimethylaminobenzoate, 7.5 parts of n-propyl methacrylate, 4.5 parts of expandable polystyrene (EPS), 14 parts of 2-methacrylic acid, 2.8 Mix one part of 2-butyl acrylate and 4 parts of 2,2'-azobisisobutyronitrile and add 25 parts of 2-oxobutane into the reaction axe, and heat it to 60 degrees Celsius, the chemical reaction starts, and stir evenly After 48 hours, the original glue solution was obtained;

[0056] (2) Photosensitive adhesive preparation: 1.3 parts of ethyl p-dimethylaminobenzoate, 3.8 parts of MCO, 2.5 parts of ETPTA, 3.3 parts of polypropylene glycol dimethacrylate, 2.7 parts of polyethylene glycol diac...

Embodiment 3

[0060] The chemical composition of the circuit board photosensitive adhesive resin glue of the 3rd embodiment of table 3

[0061]

[0062] Based on the materials in Table 3, the preparation method of the third circuit board photosensitive adhesive resin glue is as follows:

[0063] (1) Preparation of the original glue solution: 1.3 parts of ethyl 4-dimethylaminobenzoate, 6.5 parts of methacrylate stearate, 4.8 parts of high impact polystyrene (HIPS), 12 parts of MAA, 2.9 parts Mix n-butyl acrylate, 3.8 parts of 2,2'-diazoisobutyronitrile and add 20 parts of MEK into the reaction axe, and heat it to 60 degrees Celsius, the chemical reaction starts, and stir evenly for 48 hours to obtain the raw gum liquid;

[0064] (2) Preparation of photosensitive adhesive: 1.2 parts of ethyl 4-dimethylaminobenzoate, 3.2 parts of 4,4'-di(diethylamino)benzophenone, 2.8 parts of ETPTA, 3 parts of polypropylene glycol dimethyl Acrylic ester, 2.9 parts of polyethylene glycol diacrylate, 2.2 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com