Simple preparation method and application of porous g-C3N4 (graphite-phase carbon nitride) nanosheet

A technology of phase carbon nitride and porous graphite is applied in the field of simple preparation of porous g-C3N4 nanosheets, which can solve the problems of reducing interlayer hydrogen bonds and van der Waals forces, unfavorable large-scale application, low efficiency, etc., and achieves short synthesis time. , low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a porous g-C 3 N 4 Preparation methods of nanosheets.

[0023] 1. Weigh 10g of dicyandiamide and 5g of ammonium chloride respectively, mix them and place them in a semi-closed crucible, heat up to 550°C in a muffle furnace and calcinate for 2 hours, cool to room temperature, and grind to obtain yellow g-C 3 N 4 powder;

[0024] 2. Weigh g-C 3 N 4 Add 100mg of the powder into a mixed solution of 300mL isopropanol and distilled water (v / v=3:1), sonicate for 30min to obtain g-C 3 N 4 suspension;

[0025] 3. Put g-C 3 N 4 The suspension was centrifuged at 4000rpm for 5min to obtain white stable porous g-C 3 N 4 nanosheet solution.

Embodiment 2

[0027] This embodiment provides a porous g-C 3 N 4 Preparation methods of nanosheets.

[0028] 1. Weigh 10g of dicyandiamide and 15g of ammonium chloride respectively, mix them and put them in a semi-closed crucible, heat up to 550°C in a muffle furnace for 2 hours, cool to room temperature, and grind to obtain yellow g-C 3 N 4 powder;

[0029] 2. Weigh g-C 3 N 4 Powder 100mg, add 300mL distilled water, ultrasonic 45min, prepared g-C 3 N 4 suspension;

[0030] 3. Put g-C 3 N 4 The suspension was allowed to stand at room temperature for 48 hours to obtain white stable porous g-C 3 N 4 nanosheet solution.

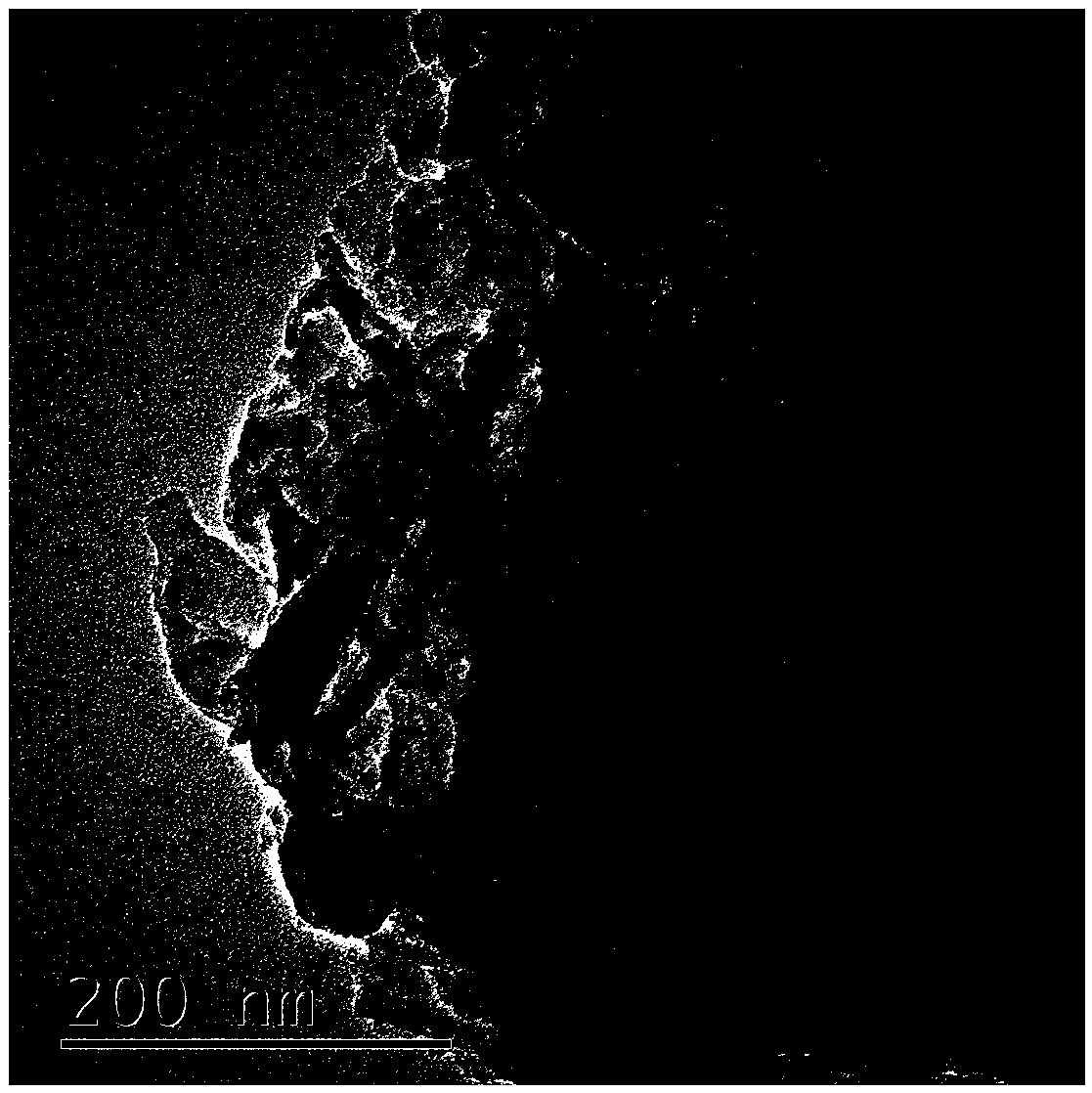

[0031] The porous g-C prepared in this embodiment 3 N 4 The transmission electron microscope (TEM) image of the nanosheets is as follows: figure 1 shown. Its flake-like structure can be seen from the figure.

Embodiment 3

[0033] This example provides porous g-C 3 N 4 Simultaneous fluorescence properties, selectivity and applications of nanosheets.

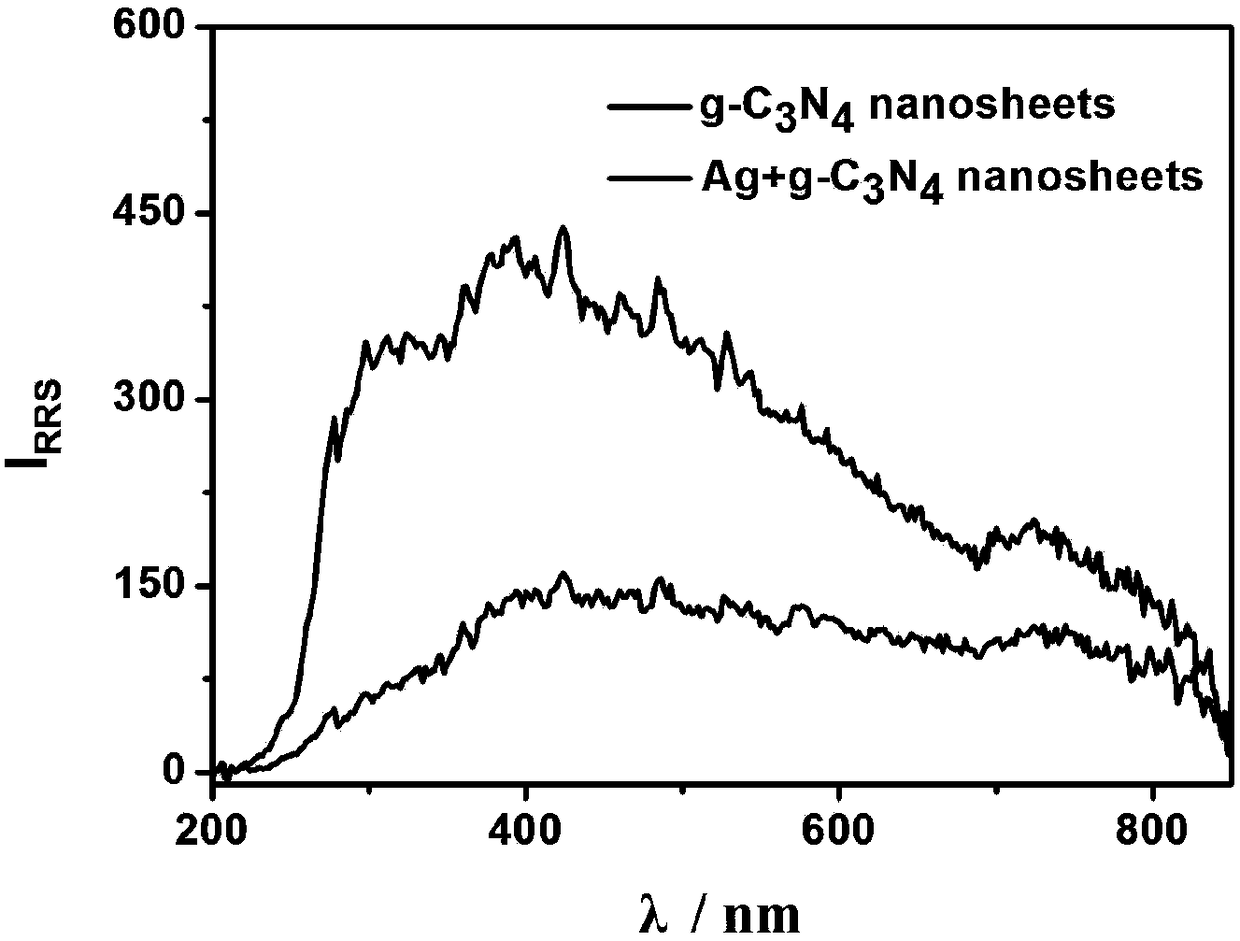

[0034] (1) Simultaneous fluorescence performance

[0035] The white stable porous g-C prepared by the present invention 3 N4 The nanosheet solution was rotovapped at 40 °C to obtain a white powder. Weigh 2 mg of white powder and disperse it in 1 L of ultrapure water, configure it into a 2 mg / L solution, and measure its synchronous fluorescence spectrum as figure 2 . It can be seen from the figure that at extremely dilute concentrations of porous g-C 3 N 4 In the nanosheet solution, there are strong synchronous fluorescence peaks.

[0036] (2) Simultaneous fluorescence enhancement, selectivity and its application

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com