Preparation method of porous g-C3N4 (graphite-phase carbon nitride) nanosheet powder

A technology of carbon nitride and porous graphite, which is applied in the field of photocatalytic material preparation, can solve the problems of high cost and complicated preparation process, and achieve the effect of complete single layer, wide source of raw materials and uniform distribution of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1, according to the mass ratio of melamine and deionized water is 1:10, and the mass ratio of Coca-Cola and deionized water is 1:600, add melamine, Coca-Cola, and deionized water to the clean polytetrafluoroethylene lining and mix, Stir evenly; put the above-mentioned polytetrafluoroethylene lining into the corresponding stainless steel jacket, tighten it, put it in an oven, keep it warm at 200°C for 12h, and after cooling with the furnace, wash the obtained solid-liquid mixture with deionized water and anhydrous The modified melamine precursor was obtained by centrifuging and washing with ethanol three times, and finally drying in an oven at 50°C for 24 hours.

[0033] Step 2. Put the precursor obtained in step 1 into an alumina crucible and cover it; heat preservation at 550°C for 4 hours, and calcining at a heating rate of 0.1°C / min to obtain porous g-C 3 N 4 powder.

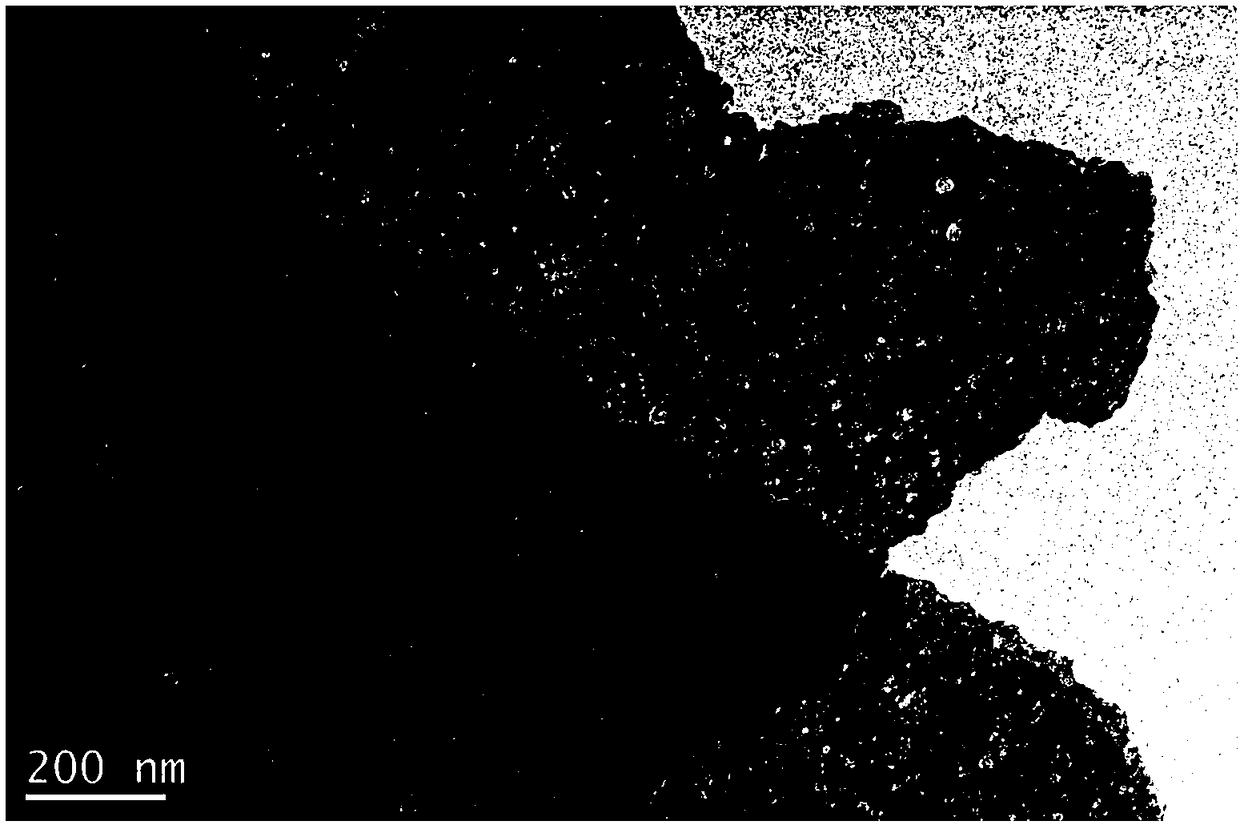

[0034] The g-C that embodiment 1 obtains 3 N 4 Powder TEM photos as figure 1 As shown, it...

Embodiment 2

[0036]Step 1, according to the mass ratio of melamine to deionized water is 1:50, and the mass ratio of Fanta to deionized water is 1:300, add melamine, Fanta, and deionized water into the clean PTFE lining Mix and stir evenly; put the above-mentioned polytetrafluoroethylene lining into the corresponding stainless steel jacket, tighten it, put it in an oven, keep it warm at 180°C for 24h, and after cooling with the oven, mix the obtained solid-liquid mixture with deionized water and The modified melamine precursor was obtained by centrifuging and washing with absolute ethanol for 4 times, and finally drying in an oven at 60°C for 20 hours.

[0037] Step 2, put the precursor obtained in step 1 into an alumina crucible and cover it; heat preservation at 530°C for 5 hours, and calcine at a heating rate of 2°C / min to obtain porous g-C 3 N 4 powder.

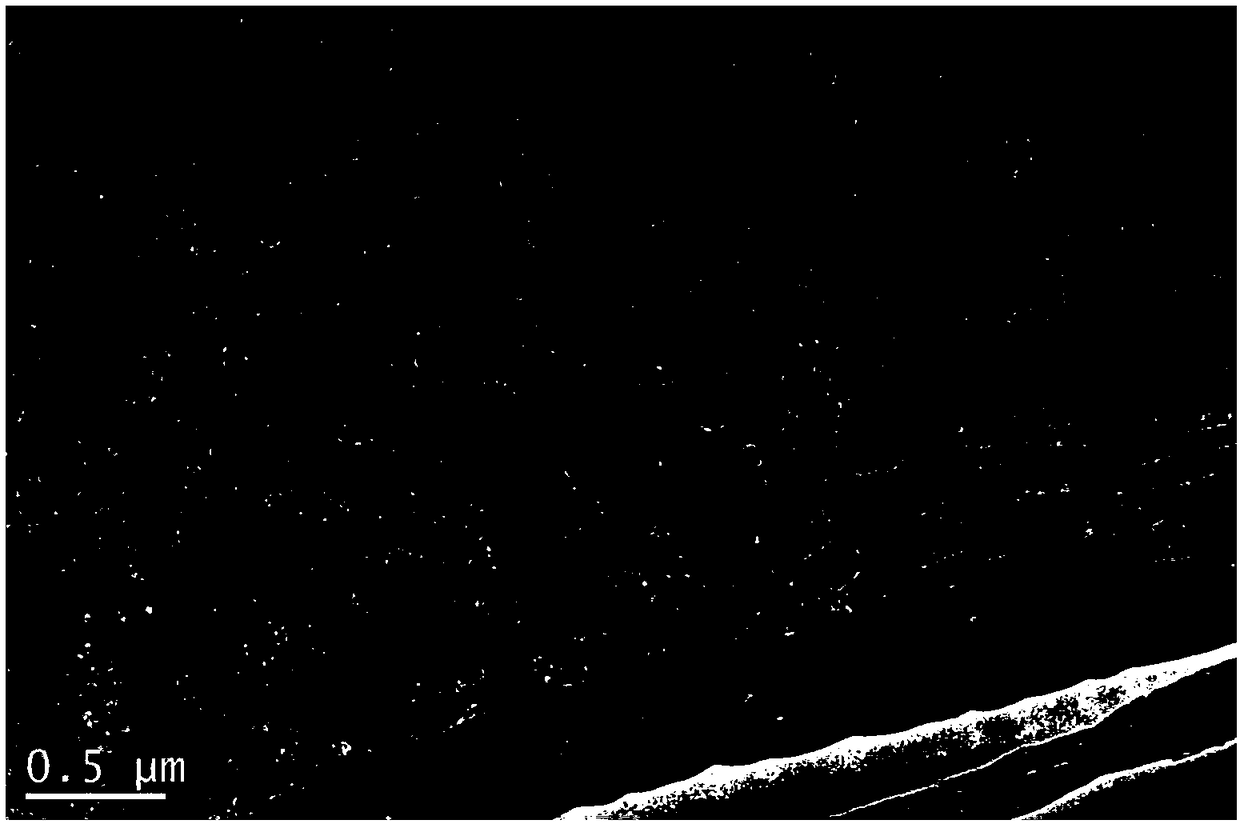

[0038] The g-C that embodiment 2 obtains 3 N 4 Powder TEM photographs, such as figure 2 As shown, it can be seen that it is an...

Embodiment 3

[0040] Step 1, according to the mass ratio of dicyandiamide and deionized water is 1:1, the mass ratio of Pepsi and deionized water is 1:1, add dicyandiamide, Pepsi, deionized water to clean polytetrafluoroethylene ethylene liner, and stir evenly; put the above polytetrafluoroethylene liner into the corresponding stainless steel jacket, tighten it, put it in an oven, keep it at 160°C for 55h, and cool it with the furnace, and use Deionized water and absolute ethanol were centrifuged and washed five times, and finally dried in an oven at 70°C for 18 hours to obtain the modified dicyandiamide precursor.

[0041] Step 2, put the precursor obtained in step 1 into an alumina crucible and cover it; heat preservation at 500°C for 6 hours, and calcine at a heating rate of 5°C / min to obtain porous g-C 3 N 4 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com