Three-dimensional network structure graphene-based material with anti-icing and deicing functions, and preparation method of material

A graphene-based, three-dimensional technology, applied in the fields of graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of slow deicing speed of deicing materials, achieve rapid heating, delay the freezing process, and reduce abnormality. The effect of the possibility of phase nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

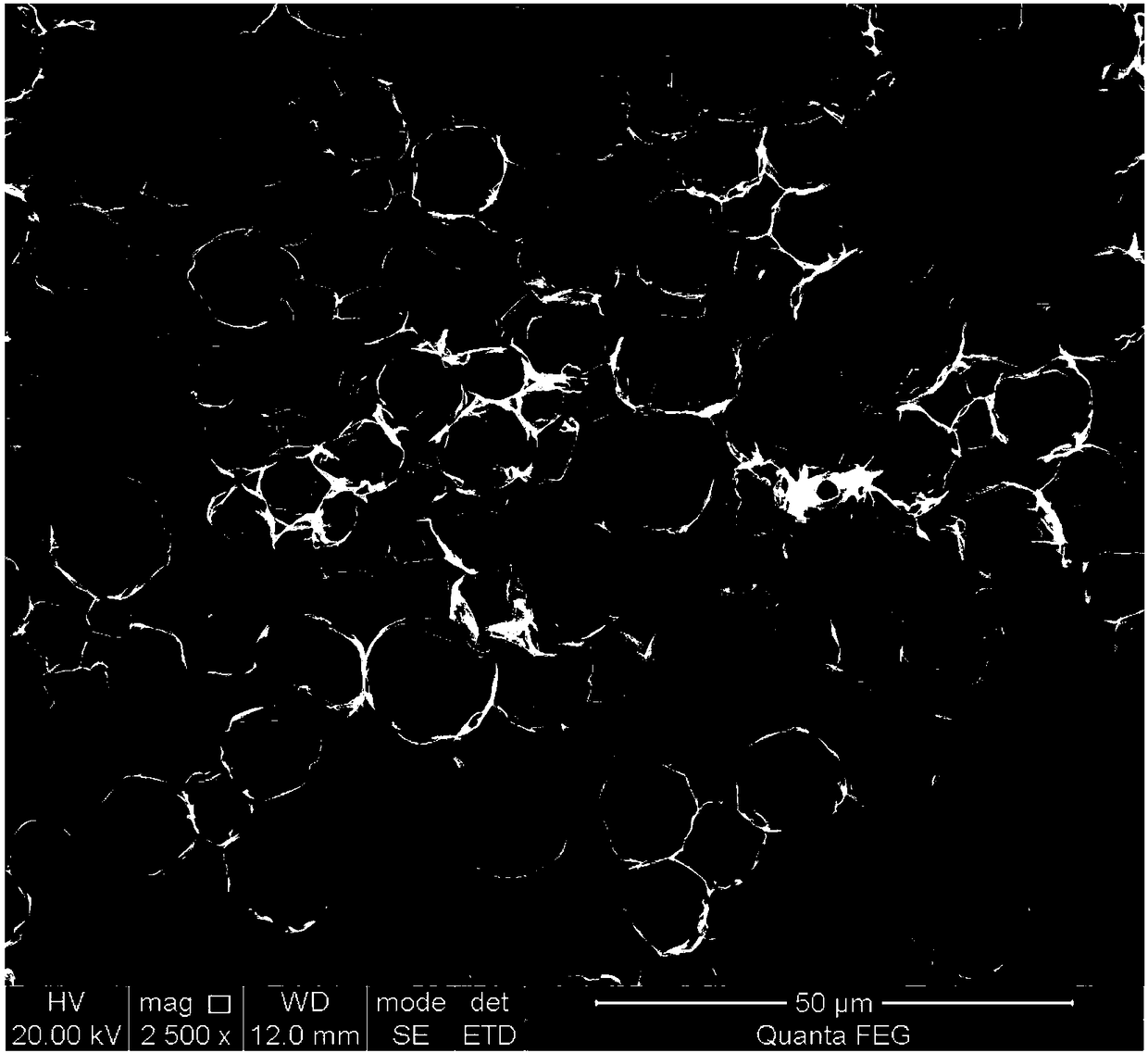

[0031] Embodiment 1: In this embodiment, the graphene-based material with anti-icing and deicing functions is composed of open-pored graphene microspheres, and the open-pored graphene microspheres are interconnected to form a three-dimensional network structure of open-pored microspheres.

[0032] The beneficial effects of this embodiment are:

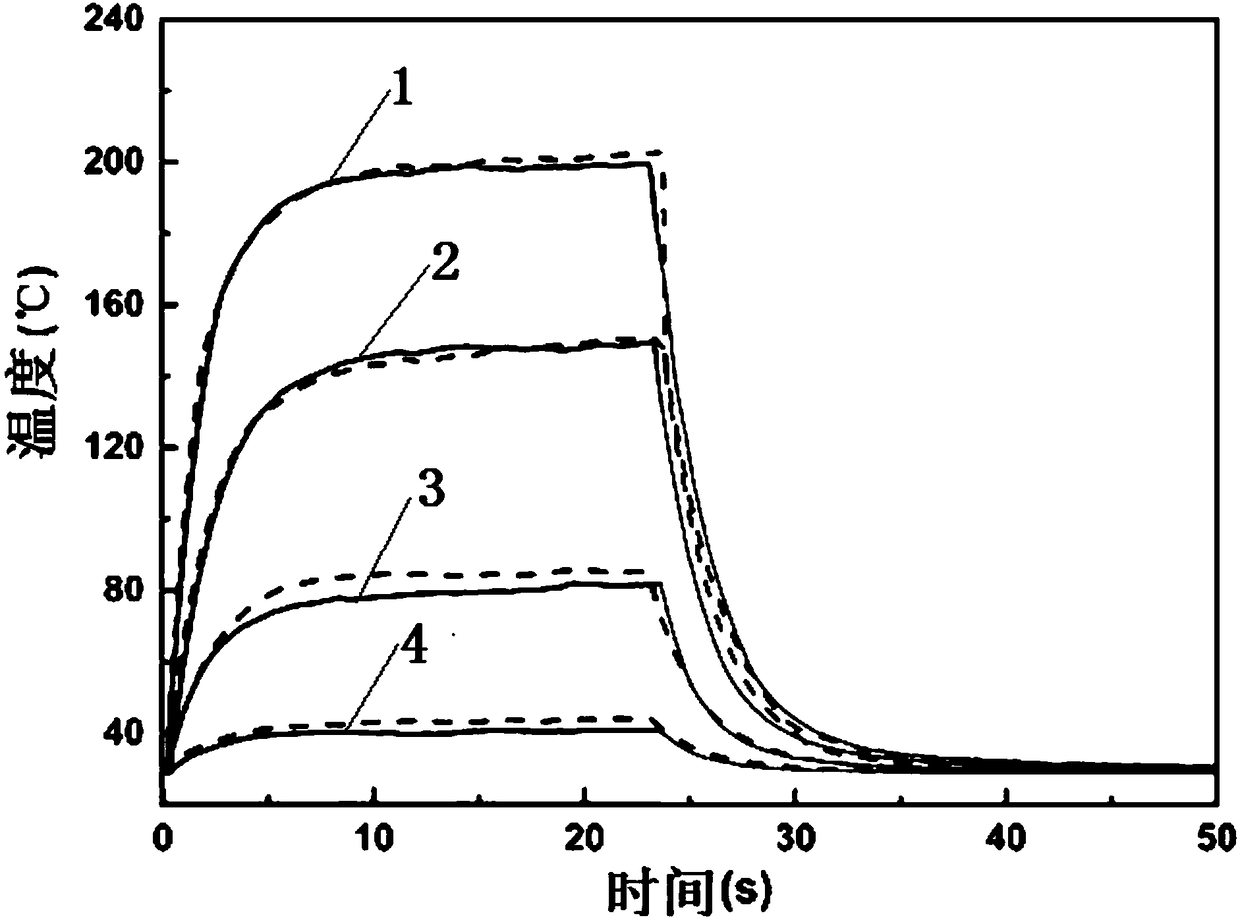

[0033] 1. The graphene-based material in this embodiment has the properties of light weight and rapid temperature rise. The graphene-based material graphene-based material prepared by the present invention has a density of 7-9 mg / cm 3 , under the voltage of 20v, the temperature is raised to 200°C in 8s, so as to achieve the purpose of rapid deicing;

[0034] 2. The surface of the graphene-based material in this embodiment is a three-dimensional network structure of open-pore microspheres, which has super-hydrophobic properties and can prevent the aggregation of water droplets; The upper solid-liquid contact surface is extremely small...

specific Embodiment approach 2

[0035] Specific embodiment two: present embodiment has the preparation method of the graphene-based material of anti-icing and deicing function to carry out as follows:

[0036] 1. Preparation of graphene oxide

[0037] 2. Preparation of graphene oxide Pickering emulsion

[0038] 3. Preparation of graphene-based materials with three-dimensional network structure of open-pore microspheres

[0039] The graphene oxide Pickering emulsion is subjected to suction filtration, and a polytetrafluoroethylene filter membrane is used during the suction filtration to obtain a polytetrafluoroethylene filter membrane loaded with graphene oxide, and then the polytetrafluoroethylene filter membrane loaded with graphene oxide is subjected to Drying, after drying, place the polytetrafluoroethylene filter membrane loaded with graphene oxide in a saturated steam of hydrogen iodide at 100-105°C for reduction, and then vacuum-dry the polytetrafluoroethylene filter membrane loaded with graphene oxid...

specific Embodiment approach 3

[0043]Embodiment 3: This embodiment is different from Embodiment 2 in that: the drying temperature in step 3 is 120-125° C., and the time is 12-13 hours. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com