System and method for treating and recycling regenerative waste liquid of macroporous denitrification resin

A technology for resin regeneration and waste liquid treatment, which is applied in chemical instruments and methods, biological water/sewage treatment, special treatment targets, etc. It can solve the problems of strict control of reaction conditions, secondary pollution by by-products, difficulty in popularization and application, etc. problems, to achieve the effects of small footprint, stable effluent quality, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate those skilled in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

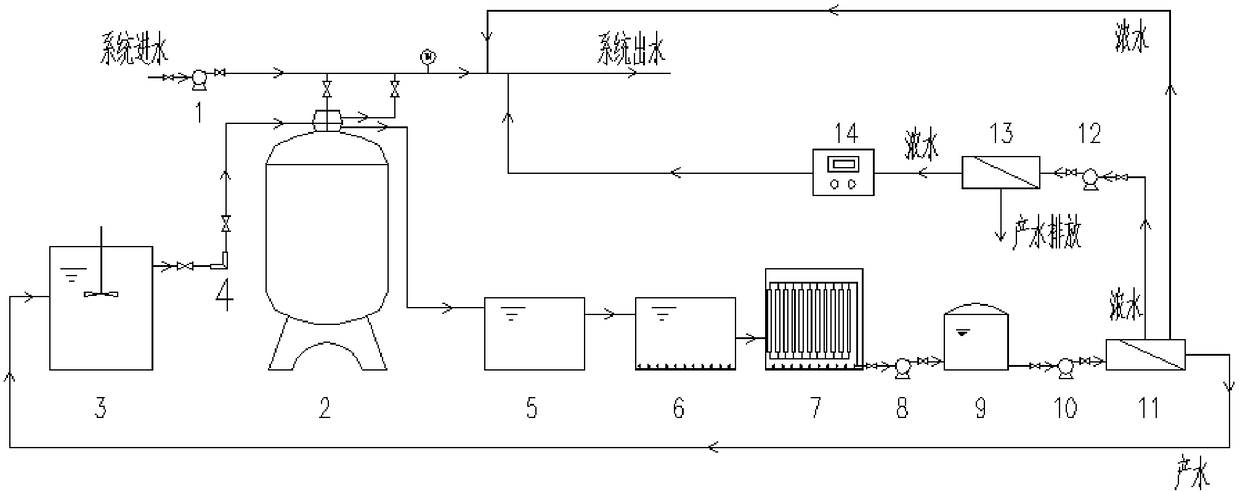

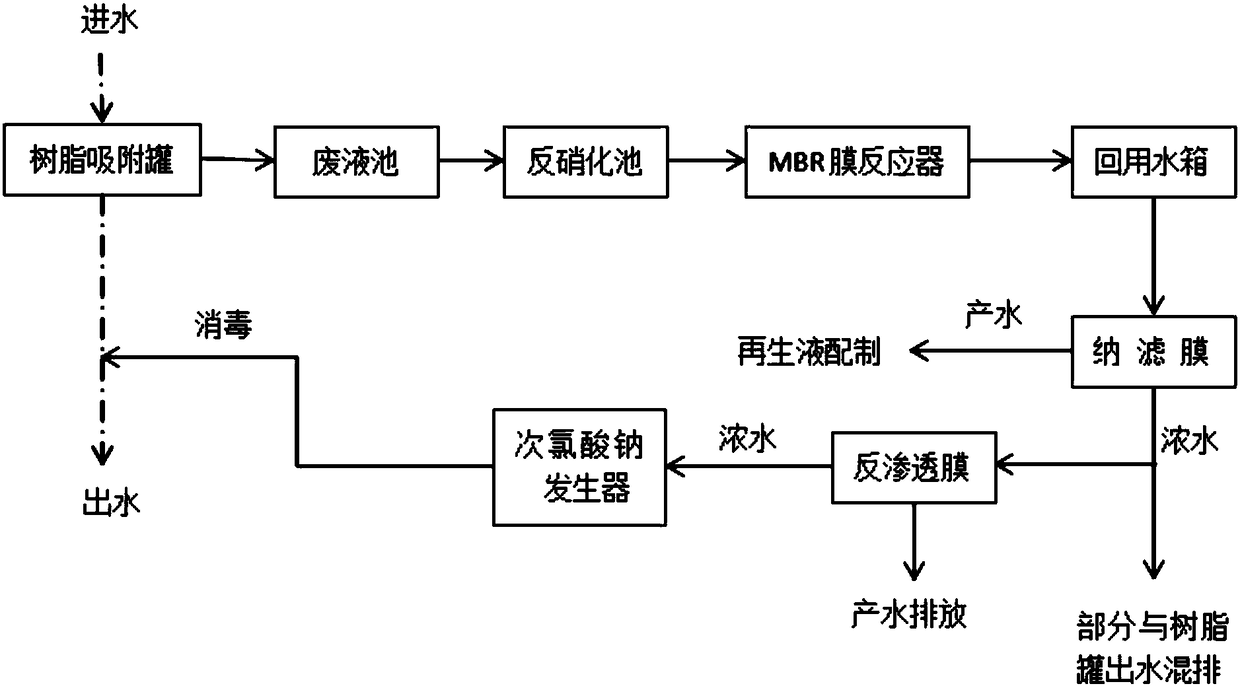

[0022] please see figure 1 , a system for treating and reusing macroporous denitrification resin regeneration waste liquid provided by the present invention, comprising water inlet pump 1, resin adsorption tank 2, sodium chloride dosing box 3, sodium chloride dosing pump 4, waste liquid Pool 5, denitrification pool 6, MBR membrane reactor 7, MBR outlet pump 8, reuse water tank 9, primary high pressure pump 10, nanofiltration membrane module 11, secondary high pressure pump 12, reverse osmosis membrane module 13, sodium hypochlorite generation device 14;

[0023] Adopt macropor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com