Aqueous fluororubber emulsion adhesive and preparation method thereof

A technology of rubber emulsion and water-based fluorine, which is applied in adhesives, adhesive additives, epoxy resin glue, etc., and can solve problems that have not been reported in research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] A water-based fluororubber emulsion adhesive. The water-based fluororubber emulsion adhesive is mainly made of water-based fluororubber emulsion, water-based epoxy resin, amine curing agent, acid absorbing agent, and emulsion film-forming aid. The parts by weight of non-volatile parts are respectively 100 parts of water-based fluororubber, 20 parts of water-based epoxy resin E-20 emulsion, 8 parts of water-based alicyclic amine curing agent EA50B, 1.5 parts of acid absorbing agent magnesium oxide aqueous dispersion, emulsion film-forming assistant Agent N,N-dimethylacetamide 4 parts.

[0029] The preparation method of a kind of water-based fluororubber emulsion adhesive described in the present embodiment comprises the following steps:

[0030] Step 1. Take a certain quality of water-based fluororubber emulsion, water-based epoxy resin, amine curing agent, acid absorbing agent, and emulsion film-forming aid respectively according to the weight and number of non-volatile...

specific Embodiment approach 2

[0044] A water-based fluororubber emulsion adhesive. The water-based fluororubber emulsion adhesive is mainly made of water-based fluororubber emulsion, water-based epoxy resin, amine curing agent, acid absorbing agent, and emulsion film-forming aid. The parts by weight of non-volatile parts are 100 parts of water-based fluororubber, 15 parts of water-based epoxy resin H220A, 8 parts of aliphatic polyamine H220B, 1 part of acid absorbent zinc oxide aqueous dispersion, and ethylene glycol butadiene as emulsion film-forming aid 2 parts ether.

[0045] The preparation method of a kind of water-based fluororubber emulsion adhesive described in the present embodiment comprises the following steps:

[0046] Step 1. Take a certain quality of water-based fluororubber emulsion, water-based epoxy resin, amine curing agent, acid absorbing agent, and emulsion film-forming aid respectively according to the weight and number of non-volatile parts, and set aside;

[0047] Step 2. Pour the w...

specific Embodiment approach 3

[0060] A water-based fluororubber emulsion adhesive, the water-based fluororubber emulsion adhesive is mainly made of water-based fluororubber emulsion, water-based epoxy resin, amine curing agent, acid absorbing agent, and its non-volatile parts by weight They are 100 parts of water-based fluororubber, 18 parts of water-based phenolic epoxy resin BH652 emulsion, 9 parts of water-based epoxy curing agent BH560, and 1.5 parts of aqueous dispersion of acid absorbing agent magnesium oxide.

[0061] The preparation method of a kind of water-based fluororubber emulsion adhesive described in the present embodiment comprises the following steps:

[0062] Step 1. Take a certain quality of water-based fluororubber emulsion, water-based epoxy resin, amine curing agent, and acid absorbing agent respectively according to the weight and number of non-volatile parts, and set aside;

[0063] Step 2. Pour the water-based fluororubber emulsion and water-based epoxy resin weighed in step 1 into...

PUM

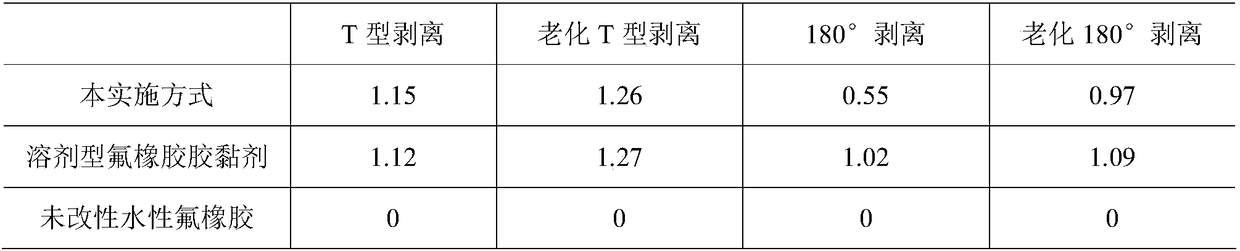

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com