Method for brewing grape vinegar by using fresh grape spirit residual liquid

A technology of table grapes and distilled wine, which is applied in the field of vinegar-making technology, can solve the problems of large differences in fermentation capacity of vinegar-making raw materials, lack of specificity of acetic acid bacteria, differences in acetic acid content and taste, and achieve mellow and mellow vinegar body. Long shelf life and strong flavor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

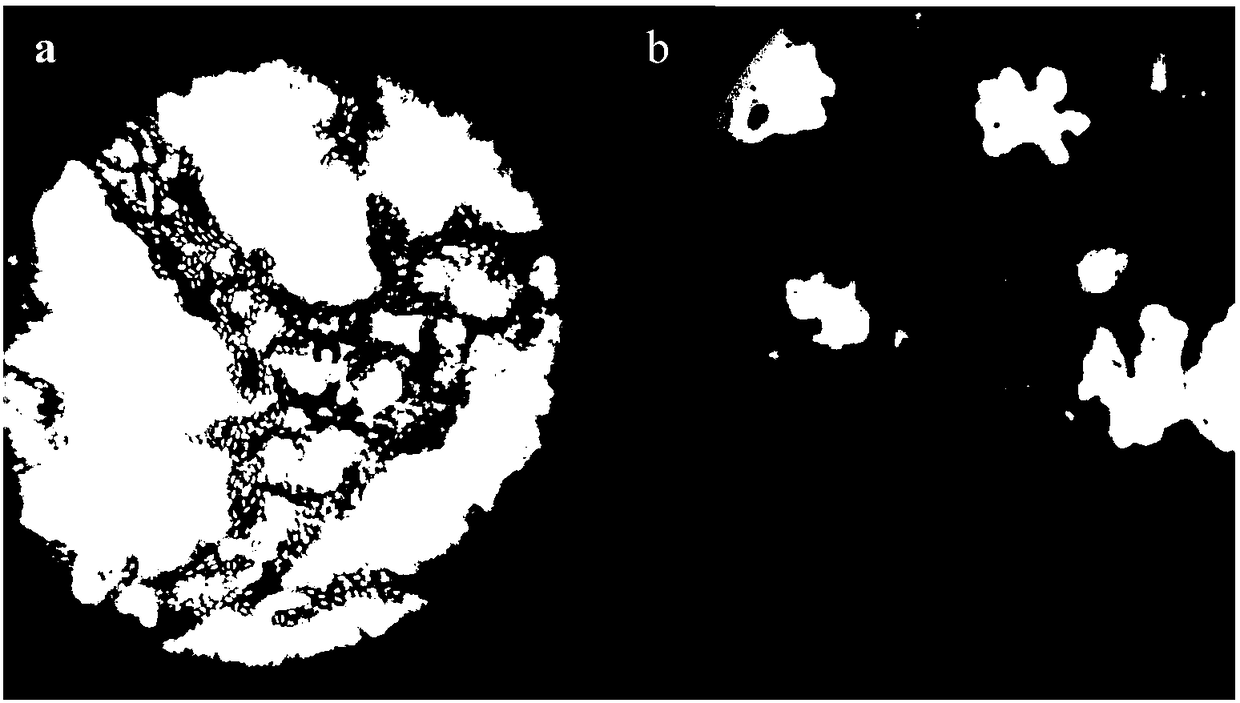

Image

Examples

Embodiment 1

[0026] Embodiment 1 obtains raffinate of grape distilled wine

[0027] 1. Isolation and purification of grape wild yeast

[0028] After the fresh grape fruit is broken, it is multiplied and cultured at 29-31° C. for 48 hours to obtain a grape wild yeast proliferation culture solution with more individuals. The obtained proliferation culture solution was diluted with sterile distilled water according to seven concentration gradients of 10 times, 20 times, 40 times, 80 times, 160 times, 320 times and 640 times, and then spread on the plate selection medium respectively (plate selection Medium formula: 4-5°Bé fresh grape pulp filtrate 24.5%, 4°Bé wort juice 24.5%, 4°Bé soybean juice 24.5%, 4°Bé potato juice 24.5%, agar 2%), each dilution concentration The gradient culture solution was used to make 4 plates, and dozens of single-cell colonies of grape wild yeast were isolated by "plate streaking method". According to the colony shape, single-cell individual shape, and growth of ...

Embodiment 2

[0068] Embodiment 2 Utilizes grape distilled wine residue to brew grape vinegar

[0069] 1. Isolation and purification of grape wild acetic acid bacteria

[0070] The fresh grape fruit is crushed and multiplied and cultured for 48 hours under the condition of 30-33° C. to obtain a multiplication culture solution of grape wild acetic acid bacteria with many individuals. The obtained proliferation culture solution was diluted with sterile distilled water according to seven concentration gradients of 10 times, 20 times, 40 times, 80 times, 160 times, 320 times and 640 times, and then spread on the plate selection medium respectively (plate selection medium) Culture medium formula: 3-4Bé grape juice 90 ml, yeast extract 1% calcium carbonate 2%, 65% alcohol 10 ml, agar 2.2%), each concentration gradient of the culture solution is made 4 plates, using the "plate streaking method" "Isolated dozens of single-cell colonies of Acetobacter viticum.

[0071] According to the colony shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com