Floating bead flotating and collecting method of microalgae

A harvesting method, microalgae technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high equipment requirements, high cost, low recovery rate, etc., to achieve increased recovery rate, Effects of reduced loss and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

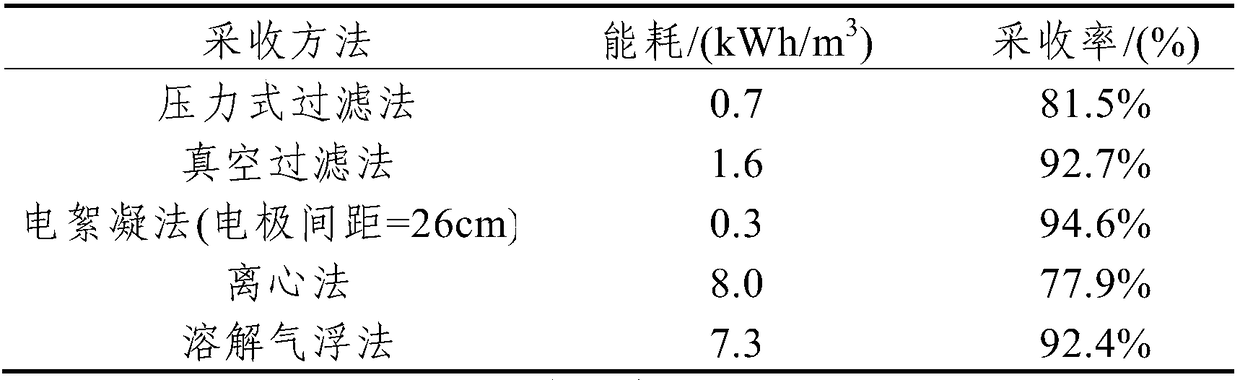

Problems solved by technology

Method used

Image

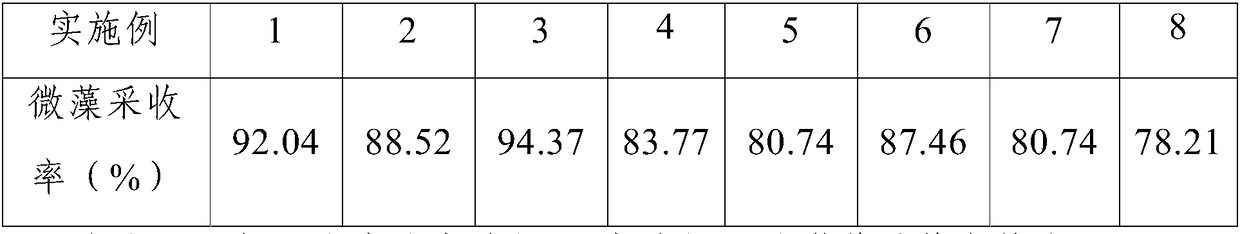

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] Step 1. Place Chlorella in a photobioreactor loaded with BG-11 medium, at a temperature of (25±1)°C, a light intensity of 3000Lux to 3500Lux, a light-dark cycle of 12L:12D, and an air flow of 15L / h, cultivate under the conditions of pH 7-7.5, and then select the chlorella suspension in the static growth period as the harvesting raw material;

[0028] 40mg chitosan flocculant was added to 2L chlorella suspension, then stirred for 1min under the condition of 250rpm, and then left to stand at room temperature for 15min to obtain the pretreated chlorella suspension; the chlorella The concentration of the suspension is 7.6×10 6 cells / mL;

[0029] Step 2. Disperse 1000 mg of floating beads in 500 mL of deionized water to form a floating bead dispersion system; the floating beads have a hollow structure, the material of the floating beads is sodium borosilicate, and the density of the floating beads is 0.35 g / cm 3 , the...

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] Step 1. Place Chlorella in a photobioreactor loaded with BG-11 medium, at a temperature of (25±1)°C, a light intensity of 3000Lux to 3500Lux, a light-dark cycle of 12L:12D, and an air flow of 15L / h, cultivate under the conditions of pH 7-7.5, and then select the chlorella suspension in the static growth period as the harvesting raw material;

[0035] Add 100mg of aluminum sulfate flocculant to 2L of chlorella suspension, then stir for 1min under the condition of 250rpm, and then let stand at room temperature for 15min to obtain the pretreated chlorella suspension; the chlorella suspension The concentration of liquid is 7.6×10 6 cells / mL;

[0036] Step 2. Disperse 1000 mg of floating beads in 500 mL of deionized water to form a floating bead dispersion system; the floating beads have a hollow structure, the material of the floating beads is sodium borosilicate, and the density of the floating beads is 0.35 g / cm 3 ...

Embodiment 3

[0040] This embodiment includes the following steps:

[0041] Step 1. Place Chlorella in a photobioreactor loaded with BG-11 medium, at a temperature of (25±1)°C, a light intensity of 3000Lux to 3500Lux, a light-dark cycle of 12L:12D, and an air flow of 15L / h, cultivate under the conditions of pH 7-7.5, and then select the chlorella suspension in the static growth period as the harvesting raw material;

[0042] 200mg of ferric sulfate flocculant was added to 2L of Chlorella suspension, then stirred for 1min under the condition of 250rpm, and then left to stand at room temperature for 15min to obtain pretreated Scenedesmus dimorphus suspension; said Scenedesmus dimorphus The concentration of the algae suspension was 15.8×10 6 cells / mL;

[0043] Step 2: Disperse 1200 mg of floating beads in 500 mL of deionized water to form a floating bead dispersion system; the floating beads have a hollow structure, the material of the floating beads is sodium borosilicate, and the density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com