Filtering and regeneration system for waste non-woven fabric

A non-woven fabric, filtration and regeneration technology, applied in textiles and papermaking, removal of solid waste, melting of filament raw materials, etc. Affecting the molecular weight distribution of polymers and other problems, achieving the effect of energy saving and environmental protection production process, reducing labor and material consumption, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

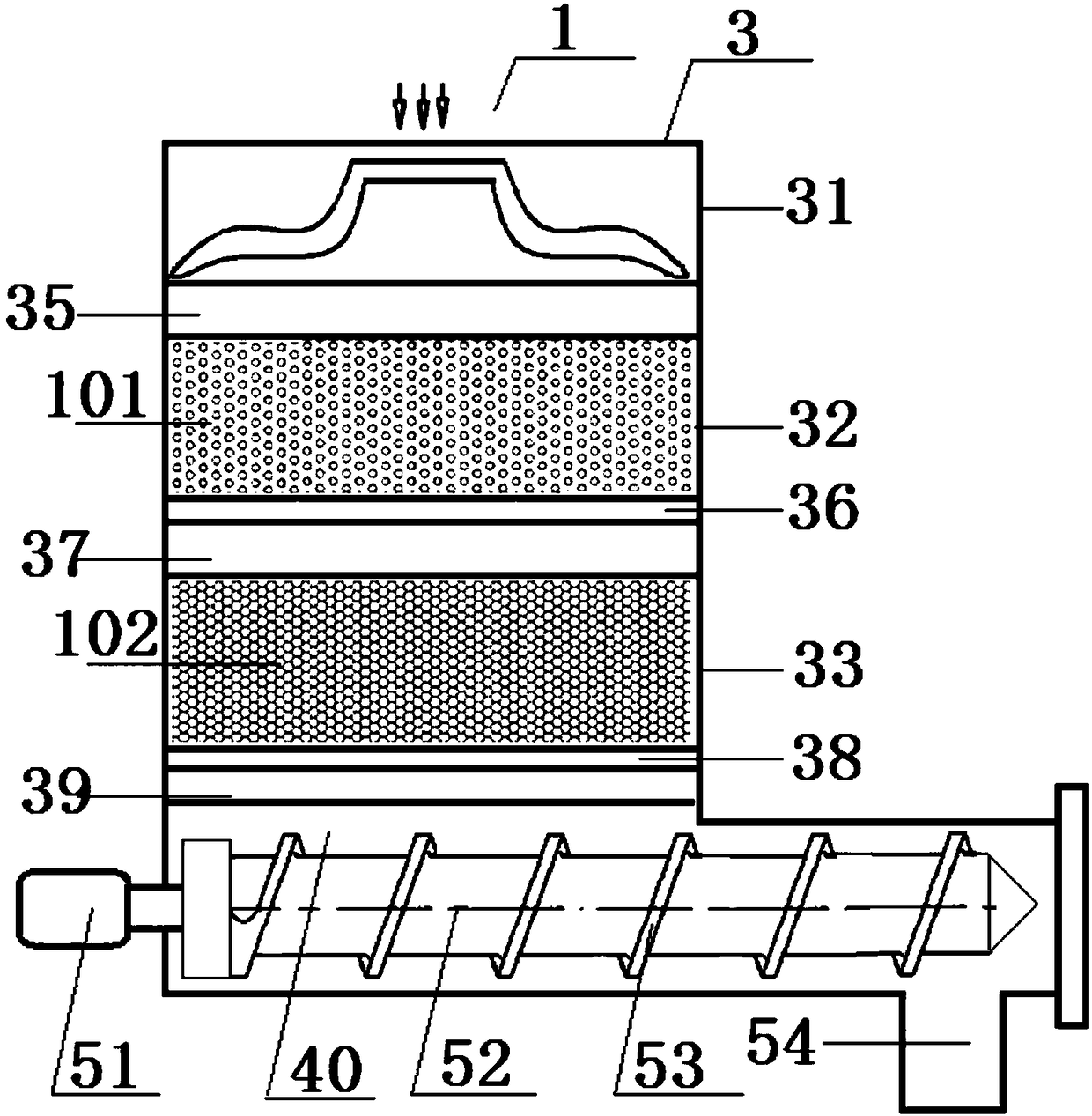

[0033] as attached figure 1 As shown, the waste filter system 1 includes a filter assembly and a material delivery assembly. The filter assembly includes a housing 3, and a top cover 31 with a feed port is arranged on the housing 3. In the housing 3 3 is provided with a feeding assembly, and at least one section of primary filter section 32 filled with coarse filter sand 101 and at least one section of fine filter section 33 filled with fine filter sand 102 are sequentially arranged in the inner cavity of the housing 3 . But in this embodiment, a section of preliminary filter section 32 and a section of fine filter section 33 are preferably set in the inner cavity of the housing 3, wherein the volume of the preliminary filter section 32 is preferably 0.13-0.15m 3 , the volume of fine filter section 33 is preferably 0.09-0.10m 3 .

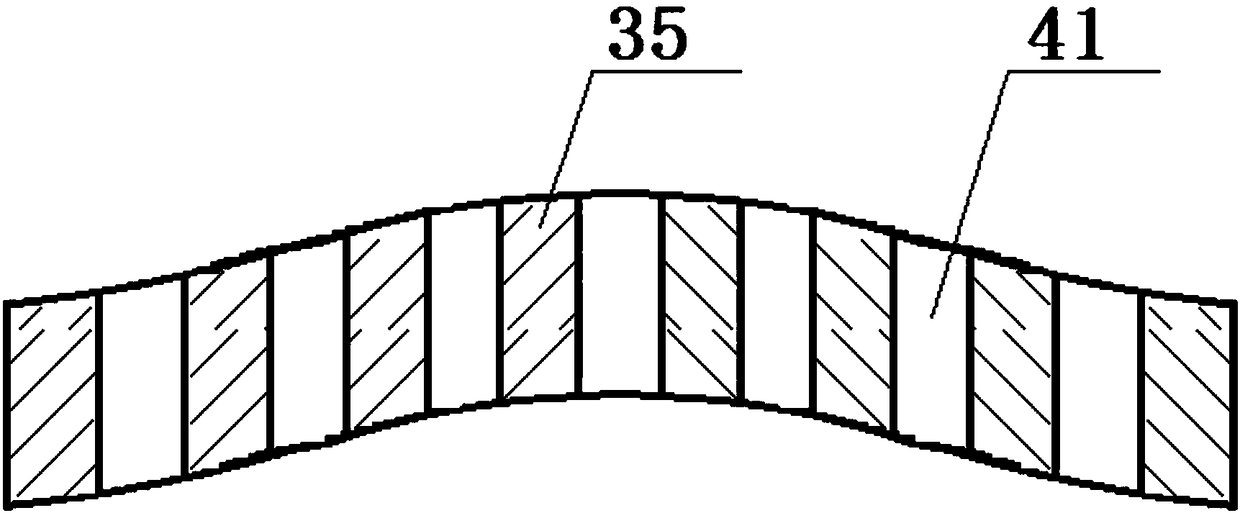

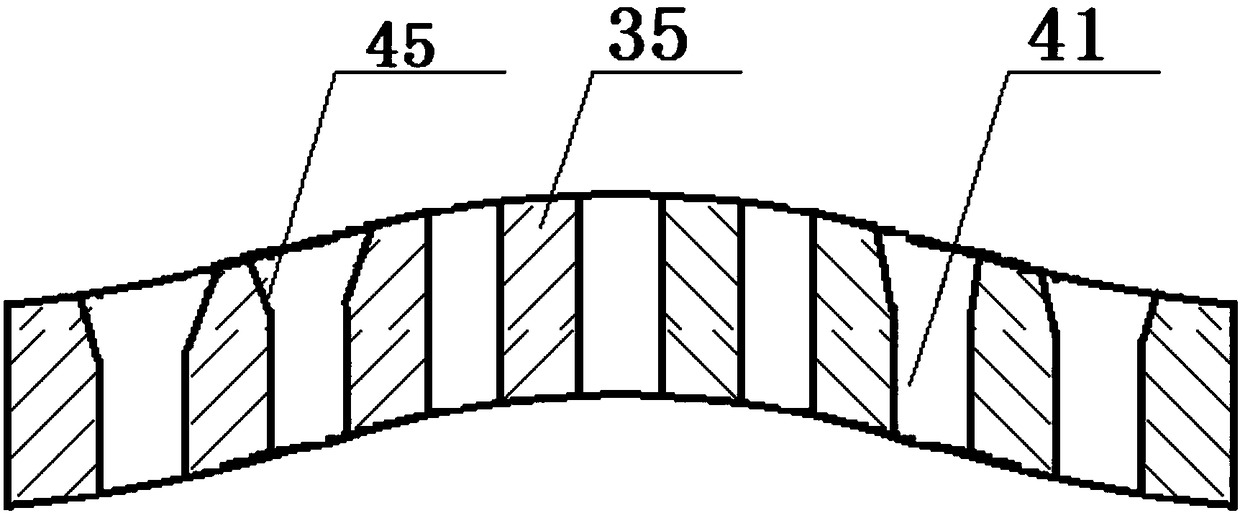

[0034] as attached figure 1 , figure 2 As shown, a cover plate is provided between the top cover 31 and the primary filter section 32, and the...

Embodiment 2

[0045] In the prior art, the components of non-woven fabrics are PP / PE or PET / PE, in which PP or PET is used as the core material, PE is the skin material, and PE is melted to produce bonding points through a heat-sealing process. . In this embodiment, recycled waste PP / PE nonwoven fabrics or scraps generated during the production process of PP / PE nonwoven fabrics are used as raw materials, and the recycled melt of waste materials is obtained through the steps of regeneration treatment.

[0046] as attached figure 1 , Figure 6 and Figure 7 As shown, in this embodiment, waste non-woven fabrics are regenerated to obtain a waste regeneration melt, including the following steps:

[0047] 1) Crushing step: In this step, the waste nonwoven fabric crushing system 21 is a crusher, and the waste nonwoven fabric is broken into sheet-like fabrics with a size not larger than 30mm×30mm by using the crusher.

[0048] 2) The step of pretreatment: adopt the hot cyclone separator 22 to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com