Method for manufacturing femtosecond laser complex components in large batch

A femtosecond laser and manufacturing method technology, applied in manufacturing tools, laser welding equipment, image data processing, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Fine manufacturing and fine engraving of patterns on the surface of large components such as satellite solid-surface antenna transmitters, radar stealth frequency selectors, and thin-walled cylinders of engine casings, such as the use of conventional laser fixed-position single-point processing combined with component movement to achieve large-scale curved surfaces Graphic manufacturing, not only the processing efficiency is low, but also the mechanical comprehensive precision of the large-stroke device directly affects the manufacturing precision of the pattern.

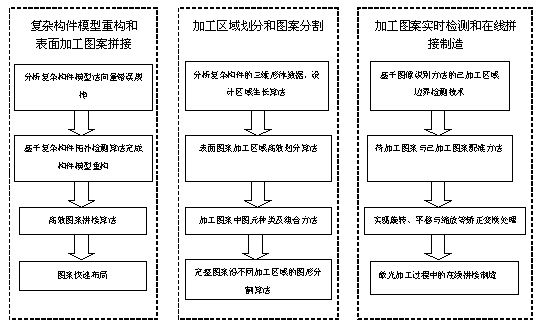

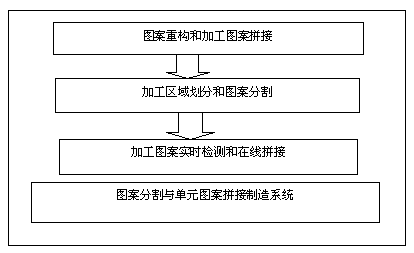

[0017] In order to improve the quality and efficiency of laser manufacturing on the surface of large and complex components, this project proposes a large-scale three-dimensional pattern precision segmentation and unit pattern online splicing manufacturing technology, which divides large components into multiple processing areas. Laser focal depth and galvanometer scanning range, design a reasonable area divis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com