Preparation method of iron, cobalt and nitrogen co-doped carbon nanofiber catalyst

A carbon nanofiber and nanofiber technology, applied in the field of fuel cell oxygen reduction catalyst materials, can solve the problems of complex preparation method, high cost, limited application, etc., and achieve the effects of simple steps, low cost, increased activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

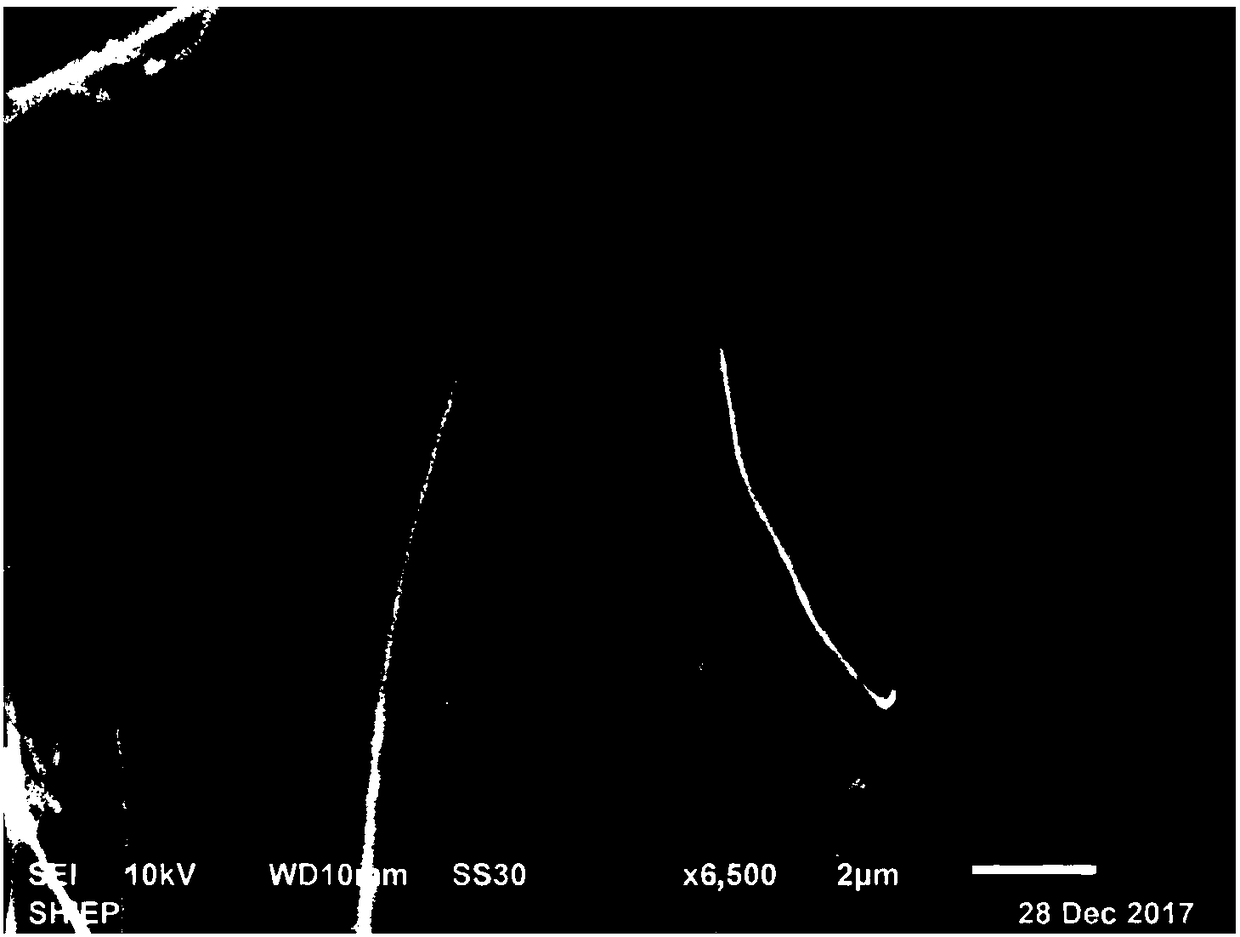

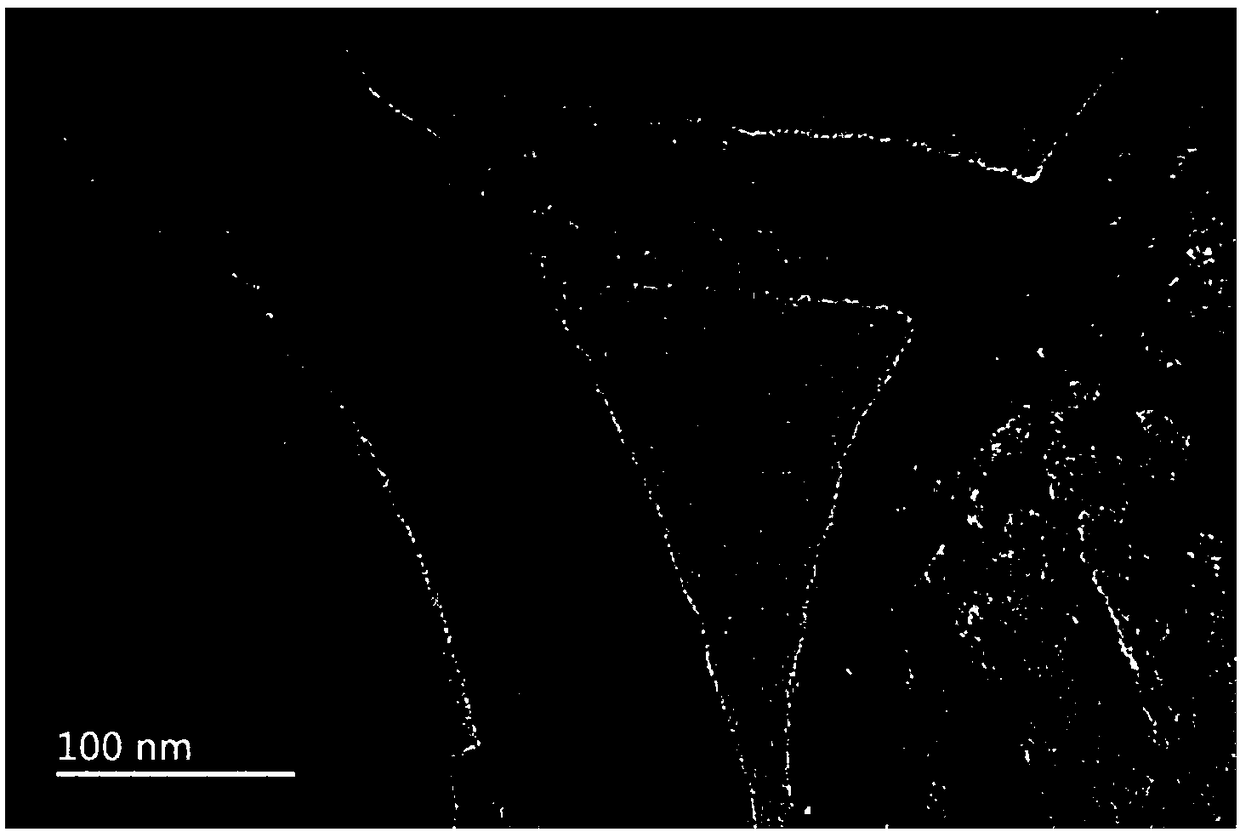

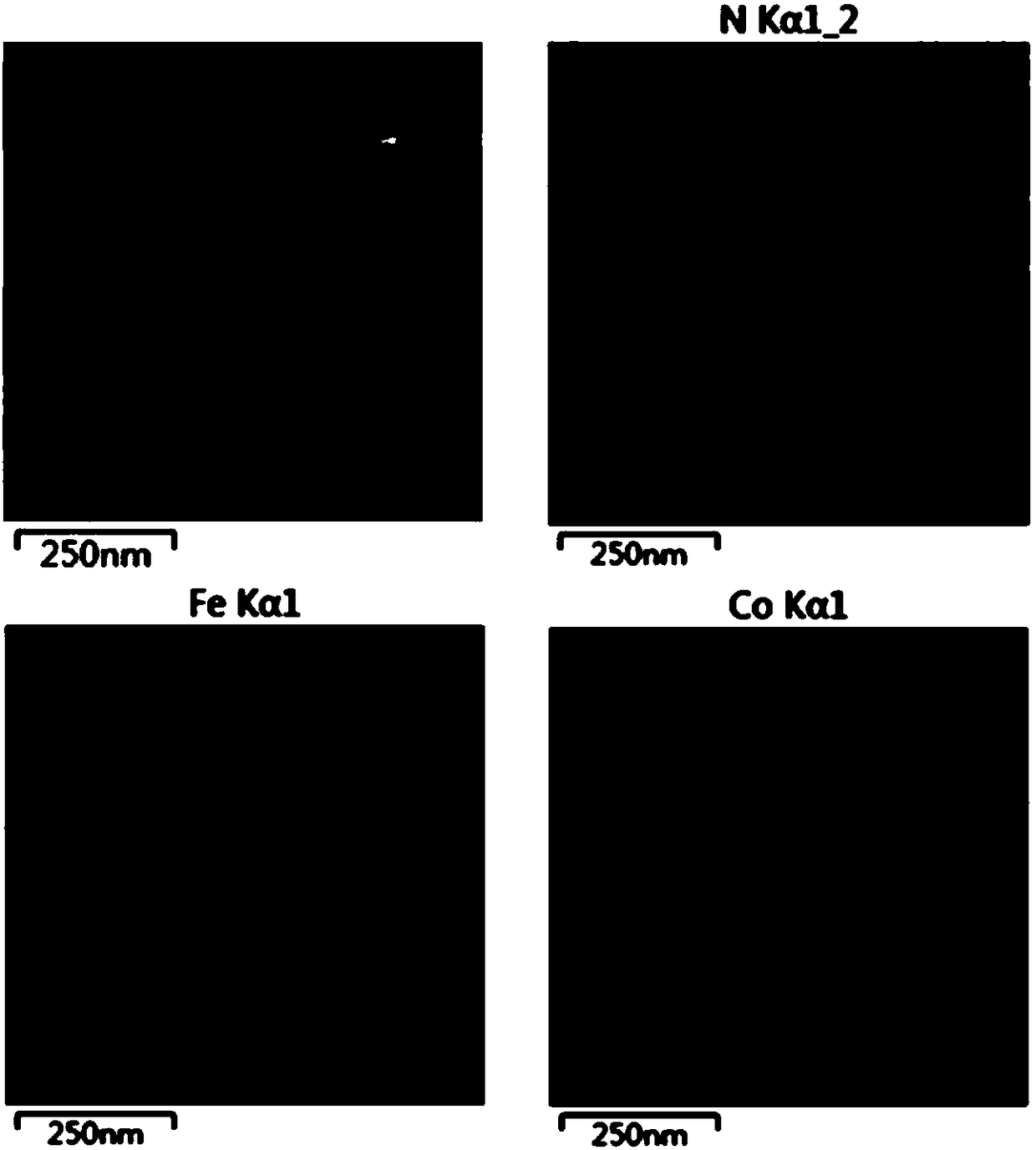

[0035] A preparation method of iron, cobalt, nitrogen co-doped carbon nanofiber catalyst, specifically comprising the following steps:

[0036] 1) Preparation of electrospinning precursor solution:

[0037] Weigh 0.1g of cobalt acetate, 1.9g of zinc acetate, and 0.2g of ferric chloride respectively, add them to 10mL of N,N-dimethylformamide, stir at room temperature until the cobalt acetate, zinc acetate, and ferric chloride are completely dissolved, Denoted as solution A. Weigh 2g of polyacrylonitrile, add it into 10mL of N,N-dimethylformamide, stir at room temperature until the solution is transparent, and record it as solution B. Solution A was added into solution B, and after stirring for 12 hours, a homogeneously mixed electrospinning precursor solution was obtained.

[0038] 2) Preparation of polymer nanofibers:

[0039] Inject the electrospinning precursor solution obtained in step 1) into a syringe with a stainless steel needle, place the syringe on the electrospinn...

Embodiment 2

[0047] A preparation method of iron, cobalt, nitrogen co-doped carbon nanofiber catalyst, specifically comprising the following steps:

[0048] 1) Preparation of electrospinning precursor solution:

[0049] Weigh 0.5g of cobalt acetate, 1.9g of zinc acetate, and 0.2g of ferric chloride respectively, add them to 10mL of N,N-dimethylformamide, stir at room temperature until the cobalt acetate, zinc acetate, and ferric chloride are completely dissolved, Denoted as solution A. Weigh 2g of polyacrylonitrile, add it into 10mL of N,N-dimethylformamide, stir at room temperature until the solution is transparent, and record it as solution B. Solution A was added into solution B, and after stirring for 12 hours, a homogeneously mixed electrospinning precursor solution was obtained.

[0050] 2) Preparation of polymer nanofibers:

[0051] Inject the electrospinning precursor solution obtained in step 1) into a syringe with a stainless steel needle, place the syringe on the electrospinn...

Embodiment 3

[0055] A preparation method of iron, cobalt, nitrogen co-doped carbon nanofiber catalyst, specifically comprising the following steps:

[0056] 1) Preparation of electrospinning precursor solution:

[0057] Weigh 0.5g of cobalt acetate, 0.95g of zinc acetate, and 0.2g of ferric chloride, respectively, and add them to 10mL of N,N-dimethylformamide, and stir at room temperature until the cobalt acetate, zinc acetate, and ferric chloride are completely dissolved. Denoted as solution A. Weigh 2g of polyacrylonitrile, add it into 10mL of N,N-dimethylformamide, stir at room temperature until the solution is transparent, and record it as solution B. Solution A was added into solution B, and after stirring for 12 hours, a homogeneously mixed electrospinning precursor solution was obtained.

[0058] 2) Preparation of polymer nanofibers:

[0059] Inject the electrospinning precursor solution obtained in step 1) into a syringe with a stainless steel needle, place the syringe on the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com