Method for preparing processed ginseng containing honey ingredients

A technology of ginseng and honey, which is applied to the functions of food ingredients, food ingredients, and food ingredients as taste improvers, etc., can solve the problems of inability to ingest beneficial ingredients of ginseng, not publicly providing ginseng with preserved nutritional ingredients, and unable to expect effects, etc. Achieve the effect of easy intake, increased speed, and rapid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

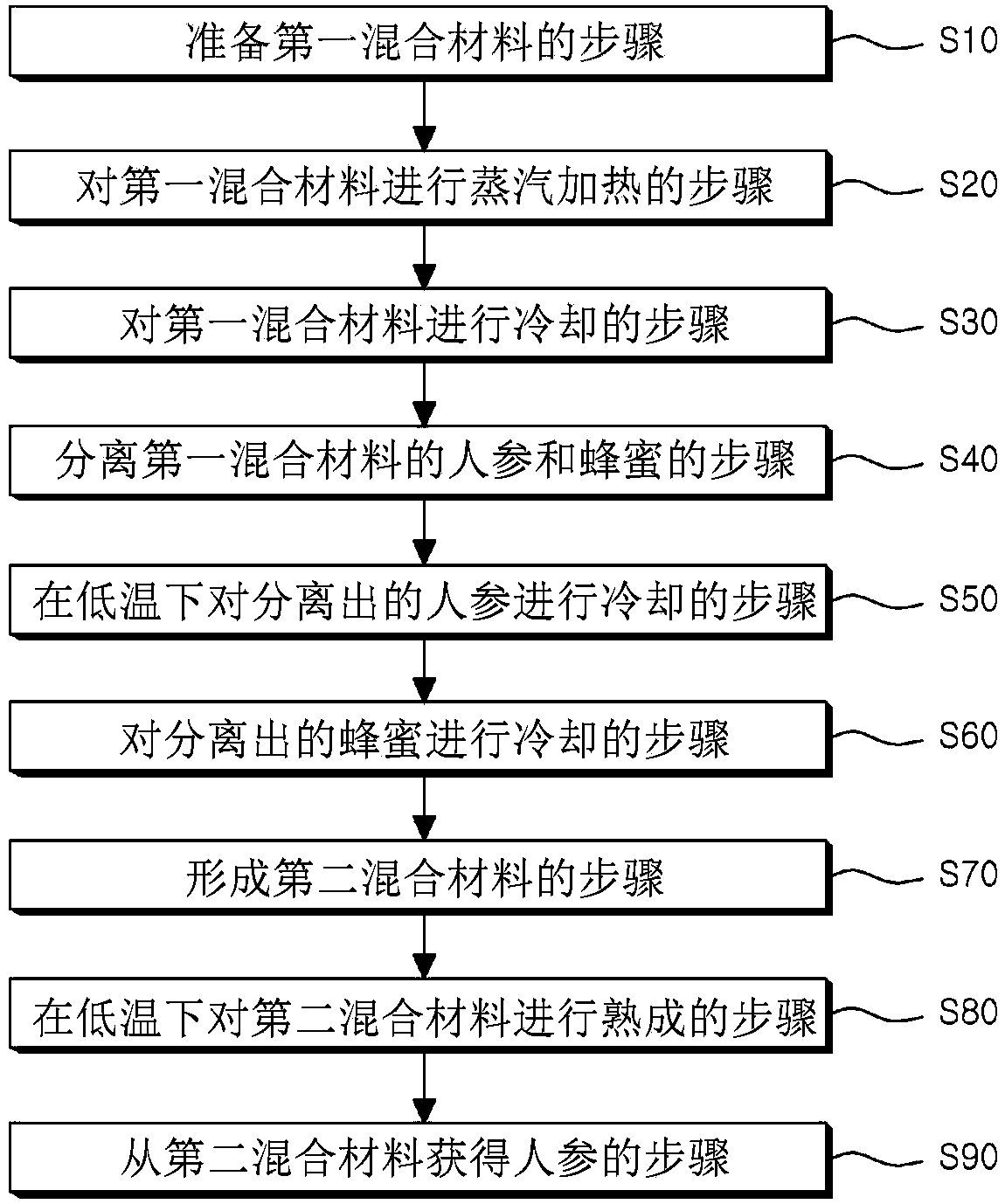

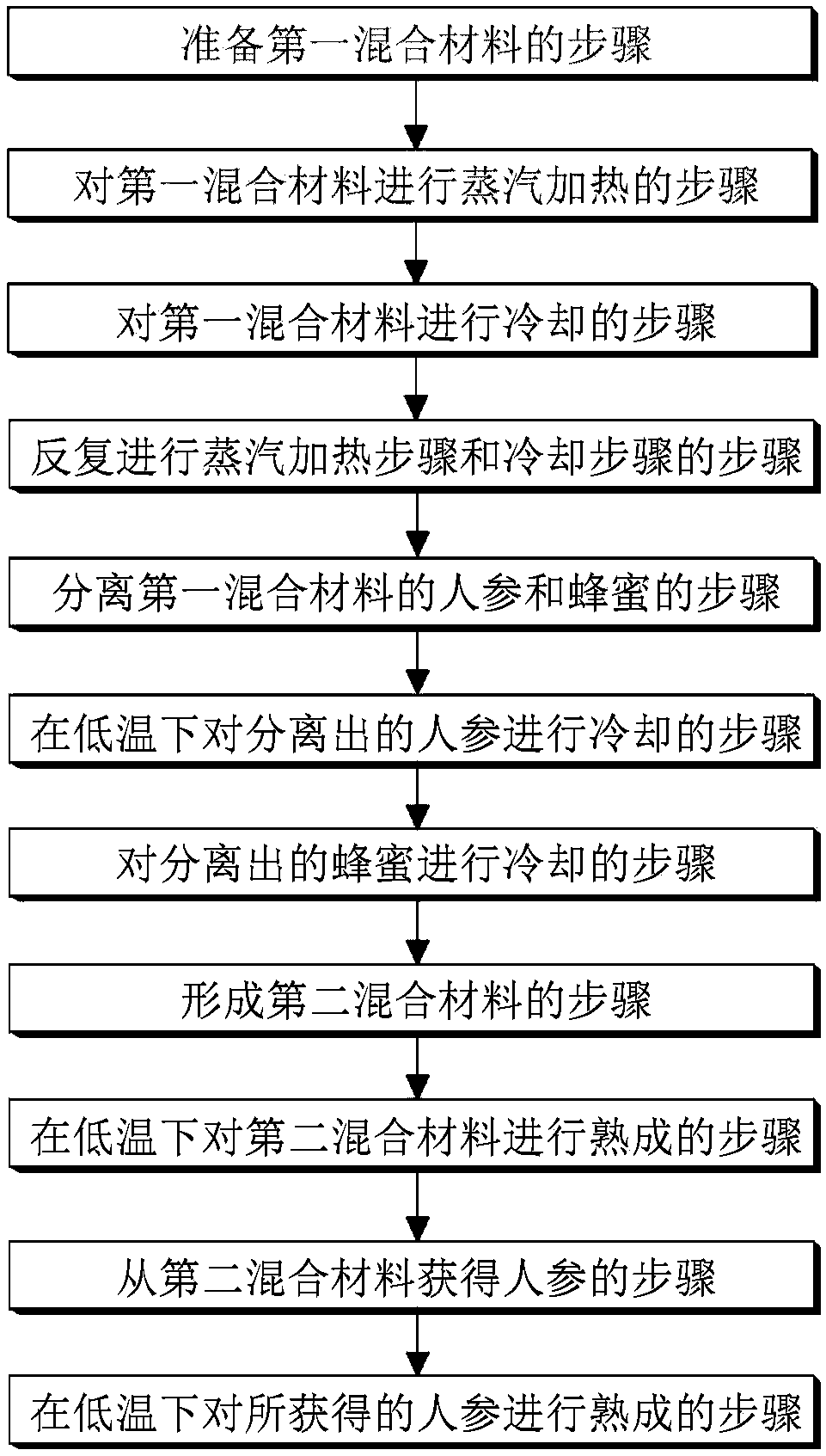

[0033] The first embodiment of the present invention relates to a method for preparing processed ginseng containing honey, comprising: a step of preparing a first mixed material containing ginseng and honey; a step of steam heating the first mixed material; The step of cooling the material; the step of separating the above-mentioned ginseng and the above-mentioned honey of the above-mentioned first mixed material; the step of cooling the separated above-mentioned ginseng at a low temperature; the step of cooling the separated above-mentioned honey at normal temperature; The step of mixing the above-mentioned ginseng cooled at low temperature and the above-mentioned honey cooled at normal temperature to form a second mixed material; the step of aging the above-mentioned second mixed material at a low temperature; and obtaining from the above-mentioned second mixed material Ginseng steps.

[0034] figure 1 and figure 2 It is a flow chart of a method for preparing processed gi...

Embodiment

[0074] Preparation of processed ginseng containing honey components

[0075] The cleaned ginseng and honey are packed into a container at a weight ratio of 1:2 to prepare the first mixed material. The first mixed material was placed inside the steam heater and covered with a lid, and steam heating was performed at a temperature of 100° C. for 6 hours while the inside was isolated from the outside. The lid of the steam heater was put on, and the steam-heated first mixed material was cooled for 45 minutes. Next, the steam heating of the first mixed material and the cooling of the steam-heated first mixed material were repeated three times. Next, ginseng and honey were separated from the above-mentioned first mixed material. The separated ginseng was matured for 18 hours at a temperature of 4° C., and the separated honey was cooled for about 18 hours at normal temperature. Next, the ginseng cooled at low temperature and the honey cooled at normal temperature were mixed to form...

experiment example

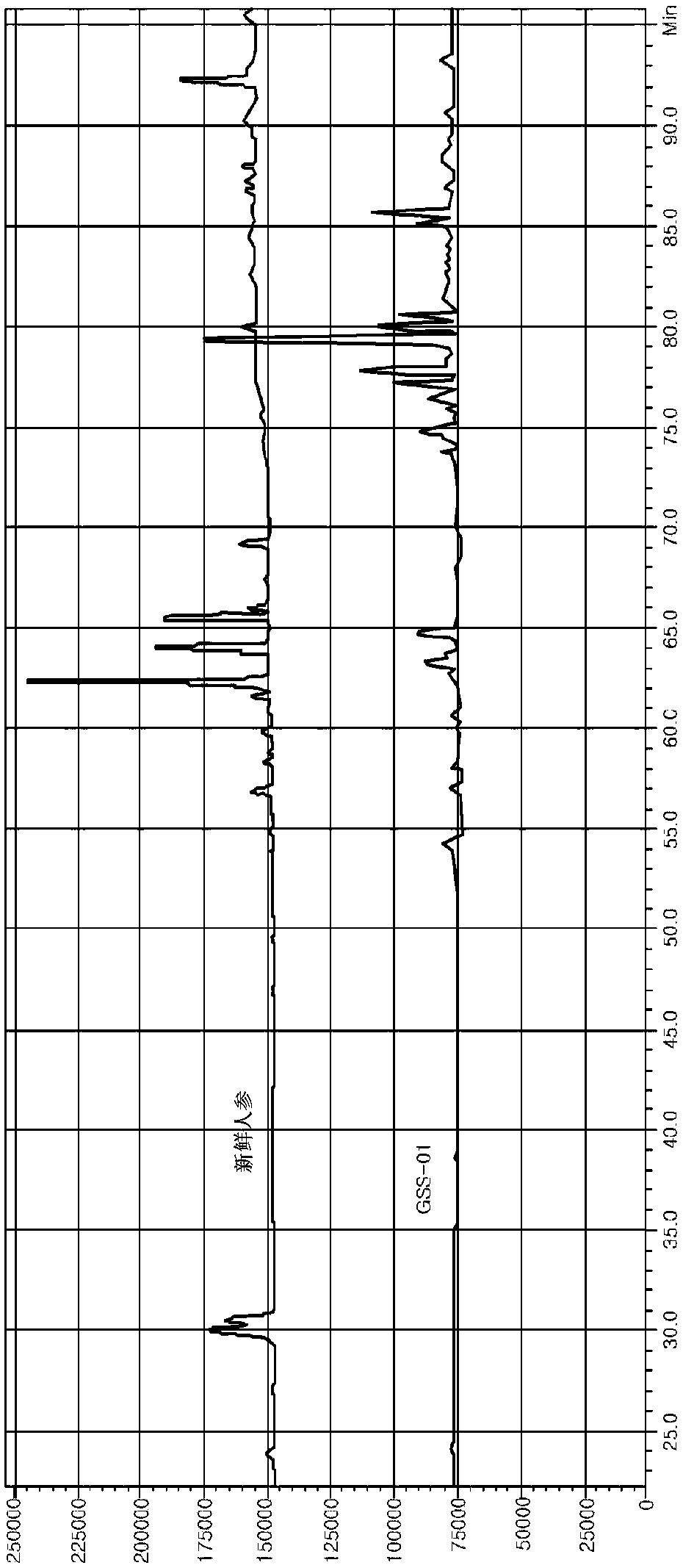

[0077] Analysis results of processed ginseng

[0078] The processed ginseng prepared in the above example was extracted in accordance with the Codex Standards for Food and Drugs and the Codex Standards for Health Functional Foods, purified with a Sep-pak cartridge, and filtered with 0.45 μm PTFE to be analyzed by HPLC. use.

[0079] As a control group, unprocessed 5-year-old fresh ginseng was prepared.

[0080] The HPLC equipment used in the analysis is Shimadzu 10Avp HPLC system (Shimadzu, Japan), and the chromatographic column uses GraceApollo RP18column 250×4.6mm, 5u (Grace, USA). Mobile phase is acetonitrile (acetonitrile) (HPLC grade, JT Baker, the U.S.) and HPLC with distilled water, with 20% (0 minutes), 20% (10 minutes), 26% (42 minutes), 40% (67 minutes), The ratio of acetonitrile was increased in order of 47% (70 minutes), 65% (80 minutes) and 65% (93 minutes), and finally adjusted to 20%. The development temperature was 40° C., the flow rate was 1.2 ml per minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com