Preparation method of titanium-steel composite board

A clad plate and titanium steel technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of interface reaction affecting the bonding performance of clad plates, reduce submerged arc sealing welding, ensure vacuum degree, prevent oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the Q235B steel grade with a substrate thickness of 66 mm is selected, the industrial pure titanium TA2 with a thickness of 6 mm as a cladding material, and a TA2 / Q235B composite plate with a thickness of 0.5+5.5 mm as a rolled product.

[0030] Ⅰ. Surface treatment: Grind the surface to be compounded of two Q235B substrate blanks and two TA2 cladding blanks, remove the rust layer and oxide layer on the surface of the blanks, and expose the fresh metal on the surface completely.

[0031] Ⅱ. Application of release agent: Apply release agent to the unpolished surface of the cladding material, and then dry the release agent.

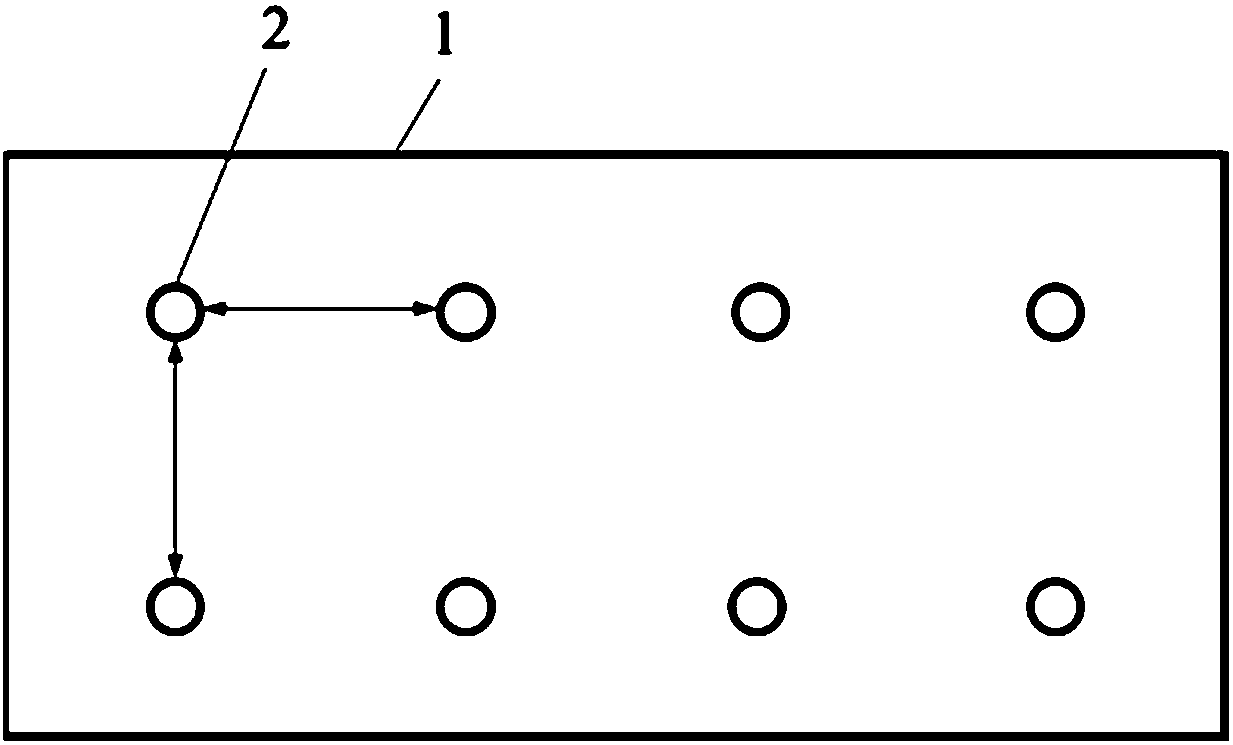

[0032] Ⅲ. Symmetrically combined blank: select one of the base materials as the blank, and fix it with seal spot welding around the surface to be compounded. The width of the seal is 30mm and the thickness is 13mm. The base material is to be compounded in the groove surrounded by the seal. every 0.5 meters (see figure 1 Arrow dis...

Embodiment 2

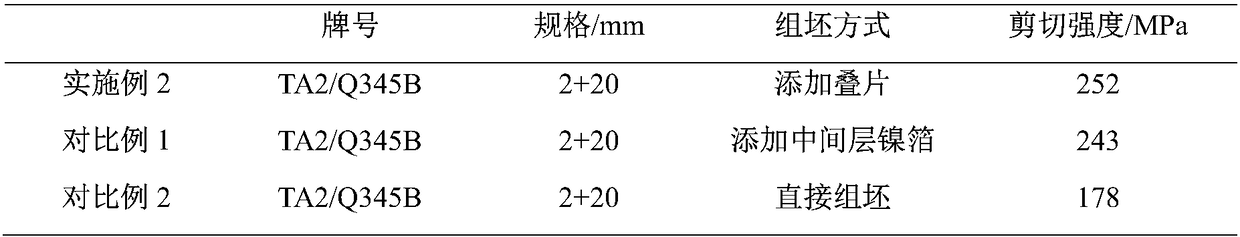

[0039] In this embodiment, a Q345B steel grade with a substrate blank thickness of 100 mm, a TA2 industrial pure titanium plate with a thickness of 10 mm as a cladding material blank, and a TA2 / Q345B composite plate with a thickness of 2+20 mm as a rolled product are selected.

[0040] Ⅰ. Surface treatment: Grind the surface to be compounded of two Q345B substrate blanks and two TA2 cladding blanks, remove the rust layer and oxide layer on the surface of the blanks, and expose the fresh metal completely on the surface.

[0041] Ⅱ. Application of release agent: Apply release agent to the unpolished surface of the cladding material, and then dry the release agent.

[0042] Ⅲ. Symmetrically combined blank: select one of the base materials as the blank, and fix it with seal spot welding around the surface to be compounded. The width of the seal is 45mm and the thickness is 23mm. The base material is to be compounded in the groove surrounded by the seal. Place a circular lamination a...

Embodiment 3

[0049] In this embodiment, a Q370R steel grade with a substrate thickness of 275mm is selected, a TA1 industrial pure titanium with a cladding thickness of 25mm, and a rolled TA1 / Q370R composite plate with a thickness of 5+55mm.

[0050] Ⅰ. Surface treatment: Grind the surface to be compounded of two Q370R base material blanks and two TA1 cladding material blanks, remove the rust layer and oxide layer on the surface of the blanks, and completely expose the fresh metal on the surface.

[0051] Ⅱ. Application of release agent: Apply release agent to the unpolished surface of the cladding material, and then dry the release agent.

[0052] Ⅲ. Symmetrically combined blank: select one of the base materials as the blank, and fix it with seal spot welding around the surface to be compounded. The width of the seal is 60mm and the thickness is 54mm. The base material is to be compounded in the groove surrounded by the seal. Place a circular lamination at intervals of 1.5 meters, the lam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com