Preparation method of nitrogen-doped porous carbon material based on citric acid transition/alkali metal complex salt

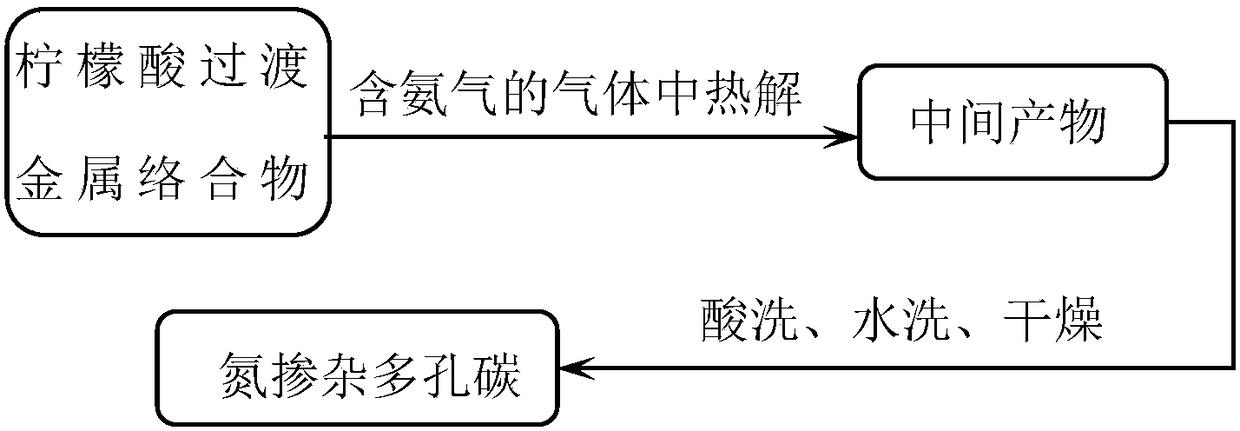

A technology of alkali metal complexes and nitrogen-doped porous carbon, which is applied in the preparation/purification of carbon, electrical components, battery electrodes, etc., can solve the complex structure and preparation process of metal complexes, expensive ligands, difficult It has been popularized to achieve excellent oxygen reduction catalytic performance and stability, promote electrocatalytic activity, and simplify the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 5g of ferric citrate and put it into an alumina porcelain boat, then put the porcelain boat into a resistance tube furnace, and inject ammonia gas after vacuuming. Set the heating rate at 5°C / min, and keep at 600°C for 2 hours. After the reaction, the obtained product was etched with 2.5 mol / L hydrochloric acid aqueous solution to remove metal impurities, then washed with water until neutral, and freeze-dried to obtain a nitrogen-doped porous carbon material.

Embodiment 2

[0034] Weigh 5g of ferric citrate and put it into an alumina porcelain boat, then put the porcelain boat into a tube furnace, and feed ammonia gas after vacuuming. Set the heating rate at 10°C / min, and keep at 900°C for 4 hours. After the reaction, the obtained product was etched with 5 mol / L hydrochloric acid aqueous solution to remove metal impurities, then washed with water until neutral, and freeze-dried to obtain a nitrogen-doped porous carbon material.

Embodiment 3

[0036] Weigh 5g of ferric citrate and put it into an alumina porcelain boat, then put the porcelain boat into a tube furnace, and inject a mixed gas of ammonia and nitrogen after vacuumizing. Set the heating rate at 0.5°C / min, and keep at 600°C for 4 hours. After the reaction, the obtained product was etched with 2.5 mol / L hydrochloric acid aqueous solution to remove metal impurities, then washed with water until neutral, and freeze-dried to obtain a nitrogen-doped porous carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com