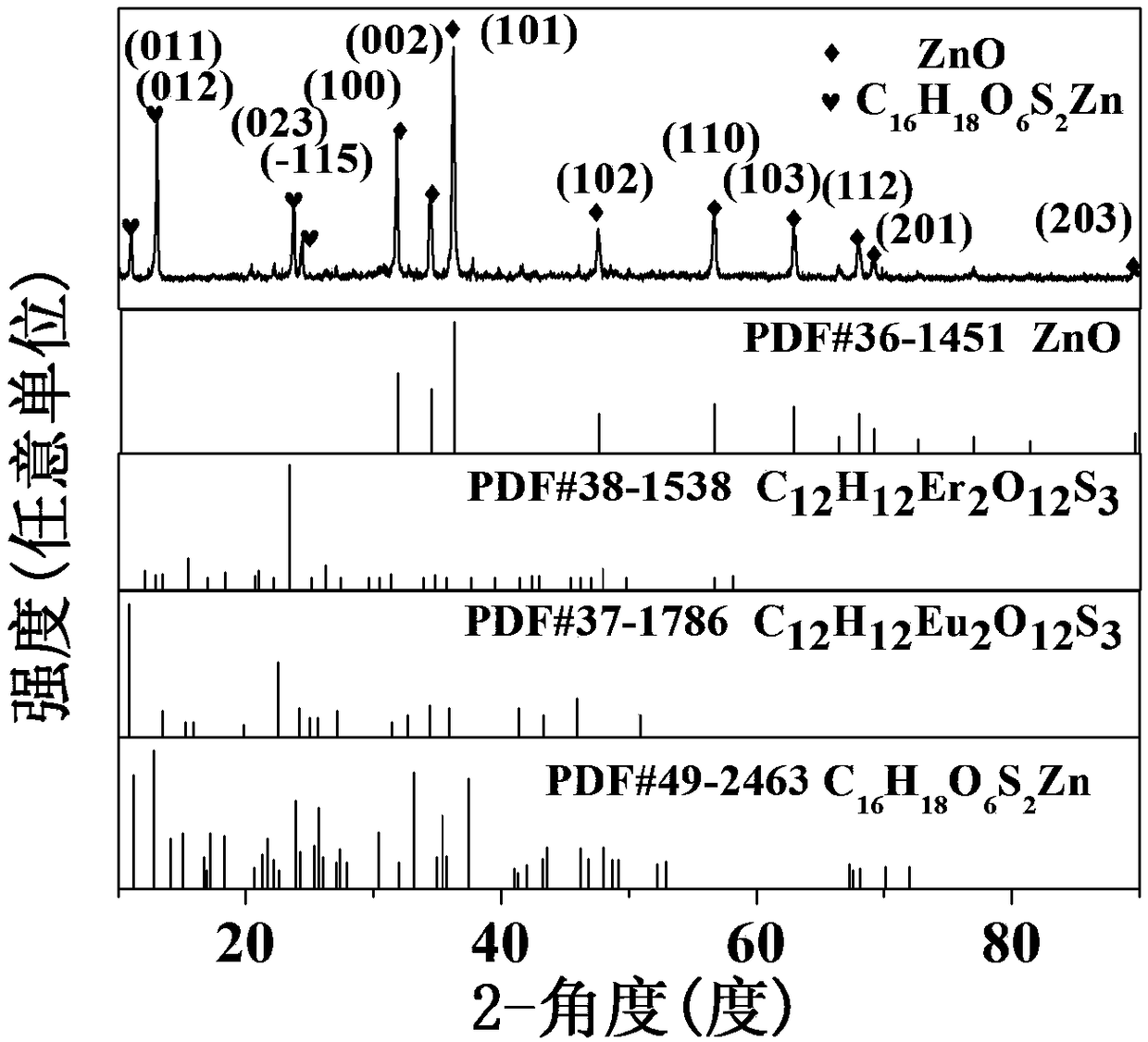

Regular rod-shaped porous Er/Eu-ZnO composite material and preparation method thereof

A composite material, eu-zno technology, used in luminescent materials, chemical instruments and methods, zinc oxide/zinc hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Weigh 1g of CTAB and dissolve it in 480mL of water, and keep stirring evenly at 80°C, then add 3.5mL of 2mol / L sodium hydroxide solution and continue stirring until uniform, then add 4.92g of zinc acetate dihydrate and continue stirring until uniform Afterwards, lithium hydroxide was slowly added until the solution was slightly alkaline, the mixture was stirred at 80°C for 2h and the resulting mixed solution was filtered, and the filtered product was dried at 60°C in an electric blower for 24h, and then The dried powdery product was put into a crucible, and calcined in a muffle furnace at 500° C. for 4 hours to obtain an ordered mesoporous zinc oxide matrix.

[0033] Weigh 0.1417g of europium chloride, 0.3408g of erbium chloride, 0.4558g of sulfosalicylic acid and 0.8000g of the ordered mesoporous zinc oxide prepared above in a clean beaker, add an appropriate amount of deionized water and continue at room temperature Stir for 48 hours, then inject the obtained mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com