A kind of preparation method of waterproof mortar

A technology of waterproof mortar and distilled water, which is applied in the field of building materials, can solve the problems of poor waterproof performance and aging, and achieve the effects of self-repair, enhanced compactness, and extended use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

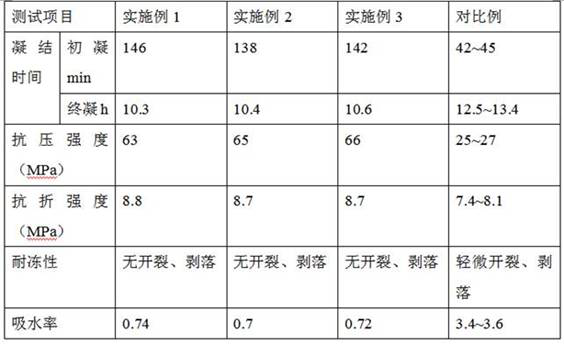

Examples

preparation example Construction

[0022] A preparation method for waterproof mortar, comprising the steps of:

[0023] (1) Take styrene and add it to the sodium hydroxide solution with a mass fraction of 5% according to the mass ratio of 1:1, stir and mix for 30~50min, let it stand for 2~3h, take the precipitate and wash it with distilled water, and distill under reduced pressure to obtain the reduced pressure Distillate, in parts by mass, takes 0.3~0.7 parts of n-bromobutane, 0.6~0.9 parts of aluminum trichloride, 80~90 parts of 1,2-dichloroethane, 30~40 parts of vacuum distillate, Stir and mix at 25-30°C for 3-4 hours to obtain a stirred mixture, take the stirred mixture and add methanol at a mass ratio of 1:6, stir and mix for 20-30 minutes, filter, and take the filter residue;

[0024] (2) Take polyvinyl alcohol and mix it with distilled water at a mass ratio of 1:40~50, heat up to 75~80°C and stir and mix for 20~30 minutes to obtain a mixture. In terms of parts by mass, take 70~90 parts of the mixture, 1~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com