A soil conditioner for enhancing crop stress resistance and its preparation and use method

A soil conditioner and crop enhancement technology, applied in soil conditioning materials, chemical instruments and methods, applications, etc., can solve problems such as failure to repair degraded soil, improvement of soil nutrient deficiency, failure to improve soil structure, etc. Effects of drought, improved crop quality, increased crop yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

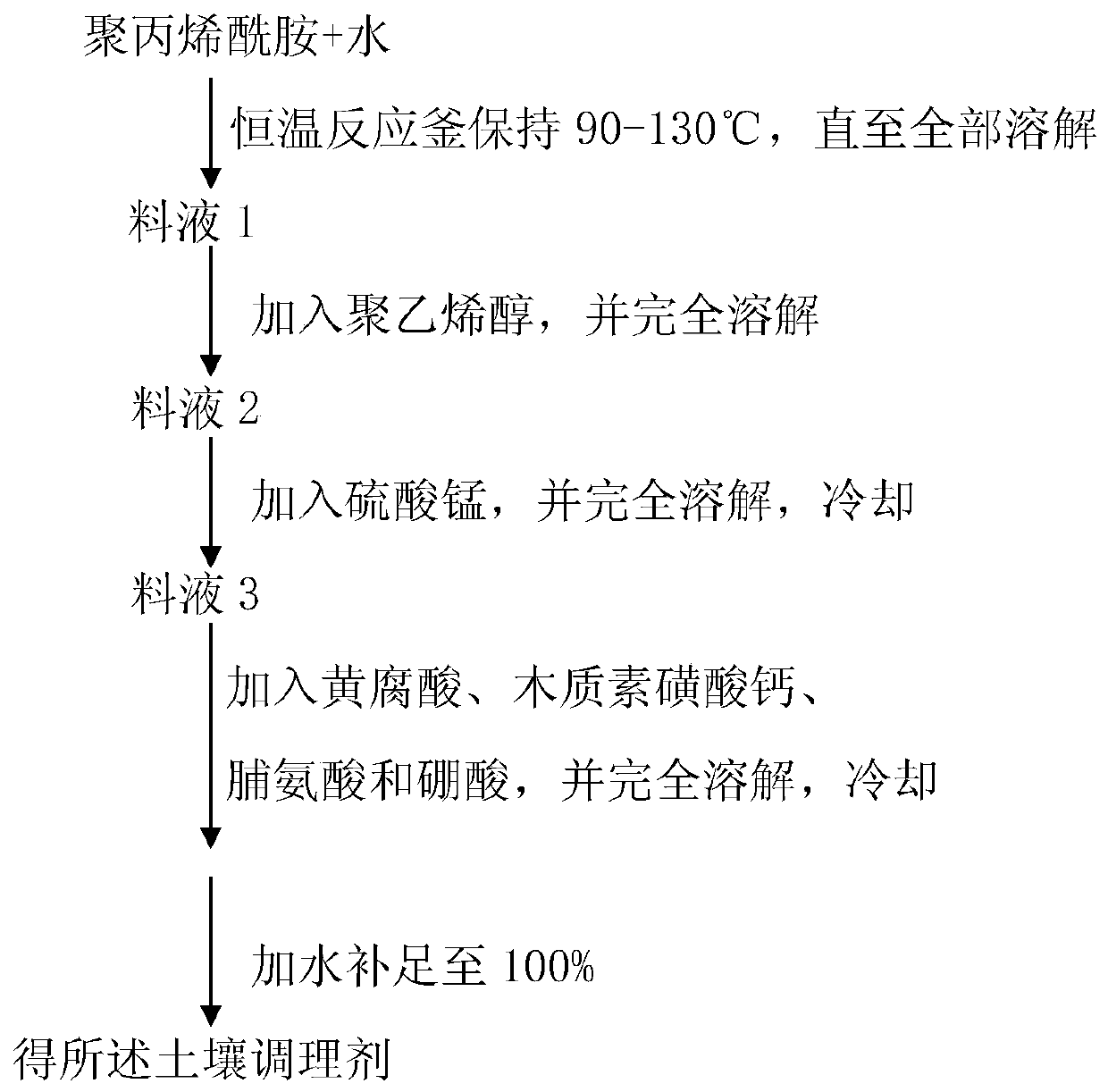

[0054] combine figure 1 Shown process flow chart, concrete preparation steps are as follows:

[0055] (1) Take 2kg of polyacrylamide in a reaction kettle, add 800kg of distilled water, heat it to 90°C to dissolve it completely, stir continuously during the dissolution process, and obtain feed liquid 1.

[0056] (2) Add 3 kg of polyvinyl alcohol to feed liquid 1, and stir continuously at 90° C. to completely dissolve it to obtain feed liquid 2.

[0057] (3) Weigh 10kg of manganese sulfate, add it into the feed liquid 2, and keep stirring continuously, without heating in this process, after making it completely dissolved, cool to room temperature to obtain the feed liquid 3.

[0058] (4) Add 50kg fulvic acid, 20kg calcium lignosulfonate, 0.05kg proline and 0.3kg boric acid to feed liquid 3, and stir until all materials are completely dissolved.

[0059] (5) There is also water loss in the process of step (1)(2), so it is necessary to weigh the weight of the feed liquid prepare...

Embodiment 2

[0070] Concrete preparation steps are as follows:

[0071] (1) Take 3kg of polyacrylamide in a reaction kettle, add 700kg of distilled water, heat it to 120°C to dissolve it completely, stir continuously during the dissolution process, and obtain feed liquid 1.

[0072] (2) Add 2 kg of polyvinyl alcohol into feed liquid 1, and stir continuously at 100° C. to completely dissolve it to obtain feed liquid 2.

[0073] (3) Weigh 20kg of manganese sulfate, add it into feed liquid 2, and keep stirring continuously, without heating in this process, after making it dissolve completely, cool to room temperature to obtain feed liquid 3.

[0074] (4) Add 70kg fulvic acid, 10kg calcium lignosulfonate, 0.1kg proline and 0.2kg boric acid to feed liquid 3, and stir until all materials are completely dissolved.

[0075] (5) There is also water loss in the process of step (1)(2), so it is necessary to weigh the weight of the feed liquid prepared in step (4) again, and then add distilled water ...

Embodiment 3

[0079] Concrete preparation steps are as follows:

[0080] (1) Take 5kg of polyacrylamide in a reaction kettle, add 500kg of distilled water, heat it to 100°C to dissolve it completely, stir continuously during the dissolution process, and obtain feed liquid 1.

[0081] (2) Add 10 kg of polyvinyl alcohol into feed liquid 1, and stir continuously at 100° C. to completely dissolve it to obtain feed liquid 2.

[0082] (3) The manganese sulfate of 50kg was weighed, added in the feed liquid 2, and kept stirring continuously, this process was not heated, after making it completely dissolved, cooled to room temperature, to obtain the feed liquid 3.

[0083](4) Add 60kg of fulvic acid, 50kg of calcium lignosulfonate, 0.01kg of proline and 0.2kg of boric acid into feed liquid 3, and stir until all materials are completely dissolved.

[0084] (5) There is also water loss in the process of step (1)(2), so it is necessary to weigh the weight of the feed liquid prepared in step (4) again,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com