Solid material continuous sterilization and fermentation equipment and continuous sterilization and fermentation system

A technology of fermentation equipment and fermentation system, which is applied in biochemical equipment and methods, solid-phase fermentation bioreactor, bioreactor/fermenter combination, etc. Pollution, slow fermentation and other problems, to achieve the effect of thorough sterilization and fermentation process, reduced labor intensity, and stable fermentation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

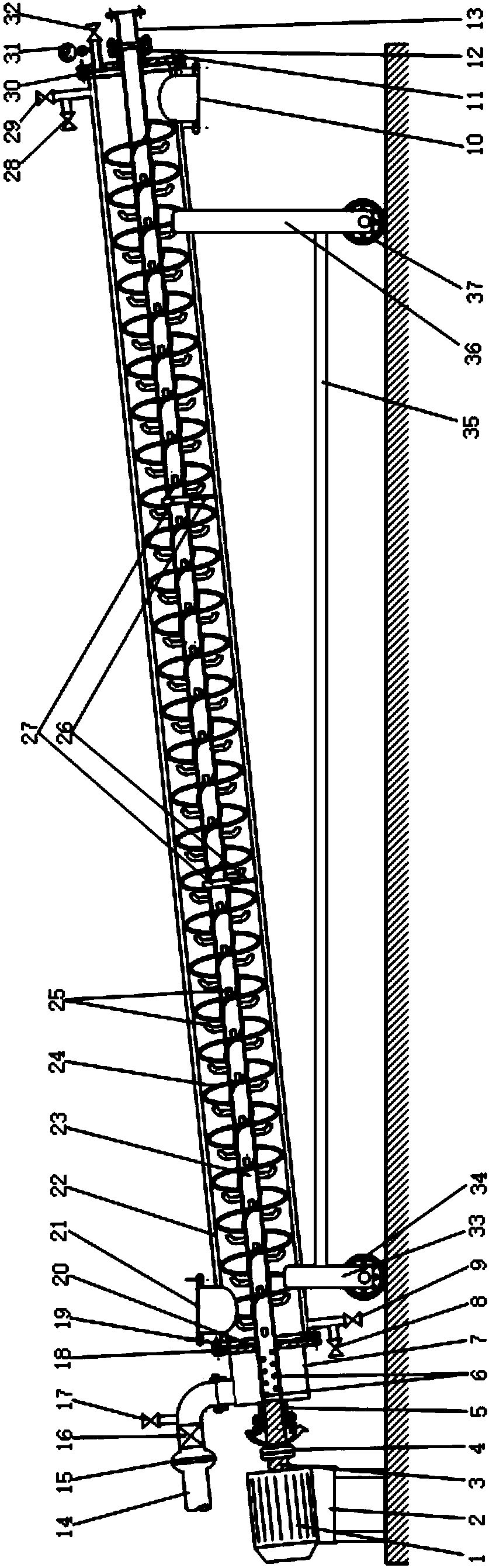

[0038] see further figure 1 , as a specific embodiment of the solid material continuous sterilization and fermentation equipment provided by the present invention, the flange sealing cover includes a left flange sealing end cover 18 and a right flange sealing end cover 11 arranged at both ends of the horizontal tank body, Wherein the right flange sealing end cover 11 is provided with an exhaust pipe communicating with the inside of the horizontal tank body, and the exhaust pipe is provided with a pressure gauge 31, a temperature and humidity sensor (not shown) and a tank pressure regulating valve 32.

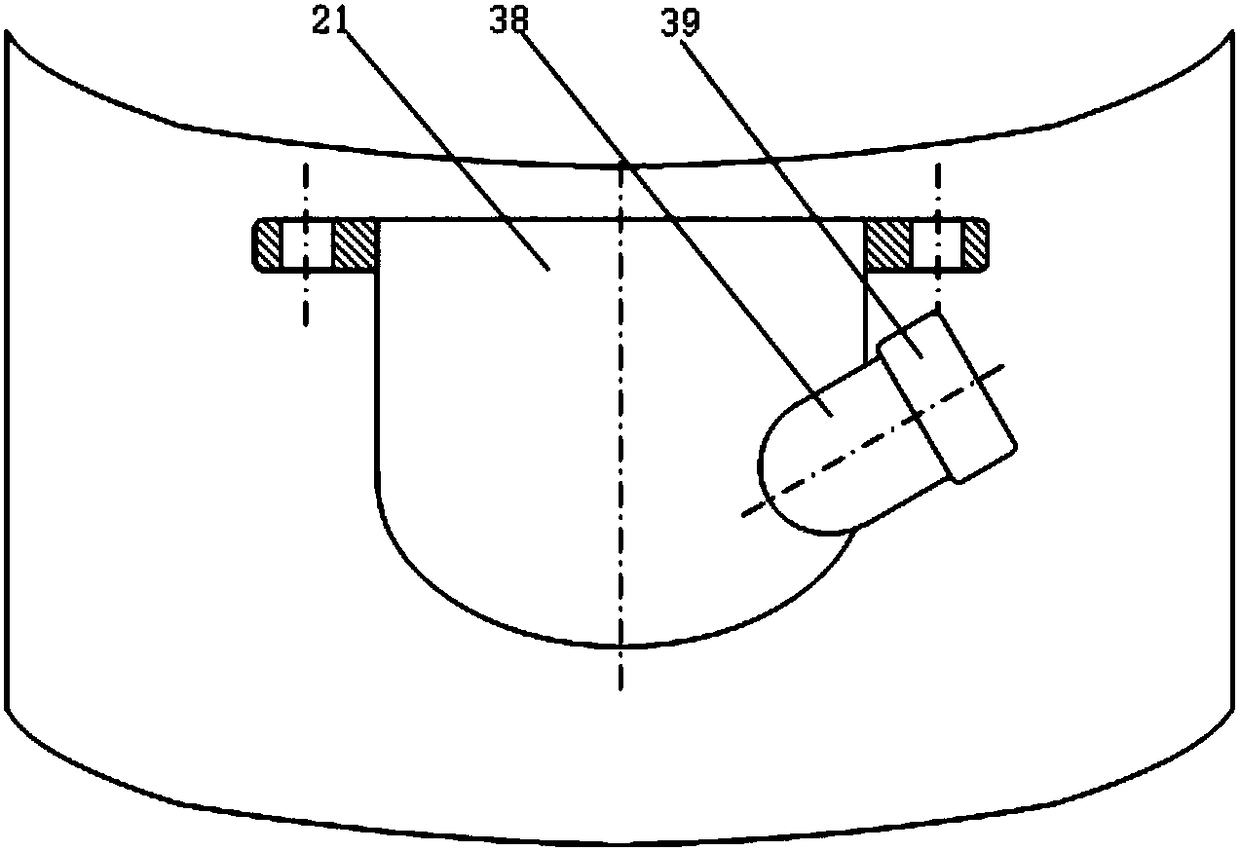

[0039] see further figure 2 As a specific embodiment of the solid material continuous sterilization and fermentation equipment provided by the present invention, the side of the feed port 21 is provided with an inoculation port 38 and a screw cap 39 for closing the inoculation port 38, which can be protected by a fire ring when inoculation is required. Open screw cap 39 down, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com