Lithium-rich positive electrode material based on surface modification of MOFs and preparation method thereof

A technology of lithium-rich cathode material and lithium-rich material, applied in battery electrodes, structural parts, electrical components, etc., can solve problems such as low electronic conductivity spinel coating, HF corrosion, etc., to improve rate performance, inhibit Corrosion, the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Surface modification of MOFs applied to lithium-rich manganese-based cathode materials Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 , prepared by the following steps:

[0040] (1) Mix N,N-dimethylformamide, absolute ethanol and deionized water at a volume ratio of 15:1:1, add 0.3g of aluminum nitrate and 0.17g of 1,3,5-benzenetricarboxylic acid to obtain mixture;

[0041] (2) Add 2 g of the lithium-rich positive electrode material to the mixed solution prepared in step (1), put it into a vacuum stirring reactor, and react at 80° C. for 2 h;

[0042] (3) The suspension obtained by the reaction is centrifuged and washed three times, and dried under vacuum to obtain a lithium-rich positive electrode material coated with MOFs;

[0043] (4) The MOFs-coated lithium-rich cathode material obtained in step (3) was placed in N 2 Sintering at 550 °C for 2 h under atmosphere to obtain MOFs-modified lithium-rich cathode materials.

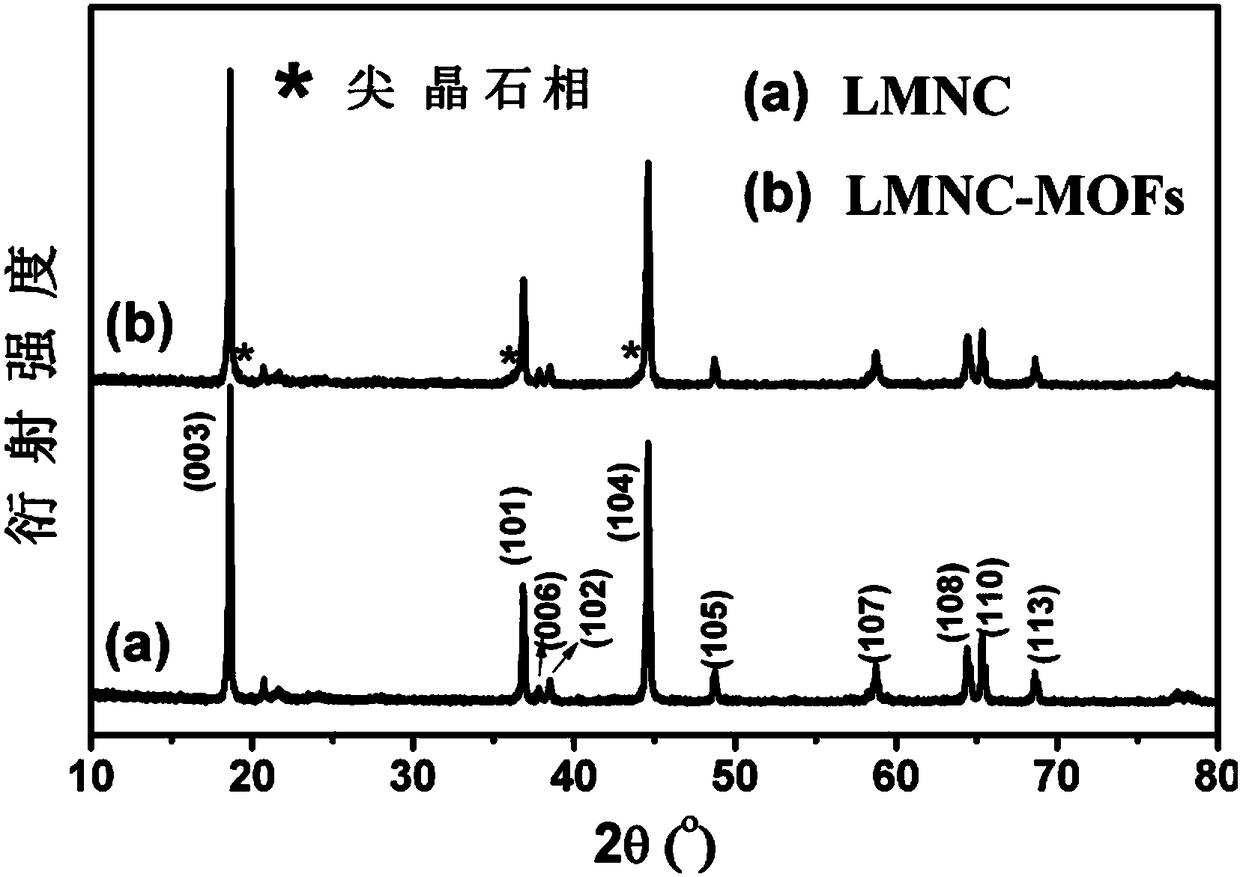

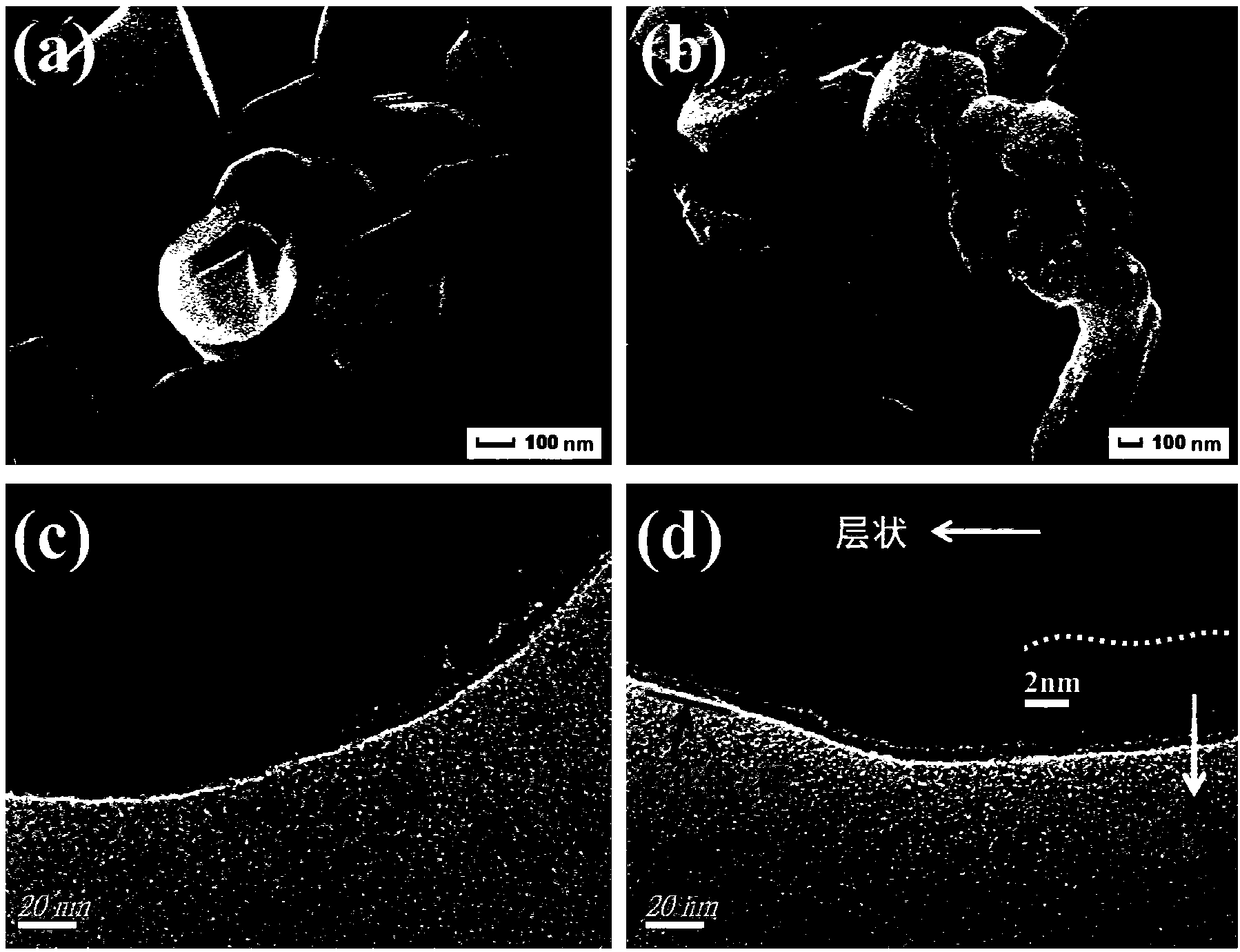

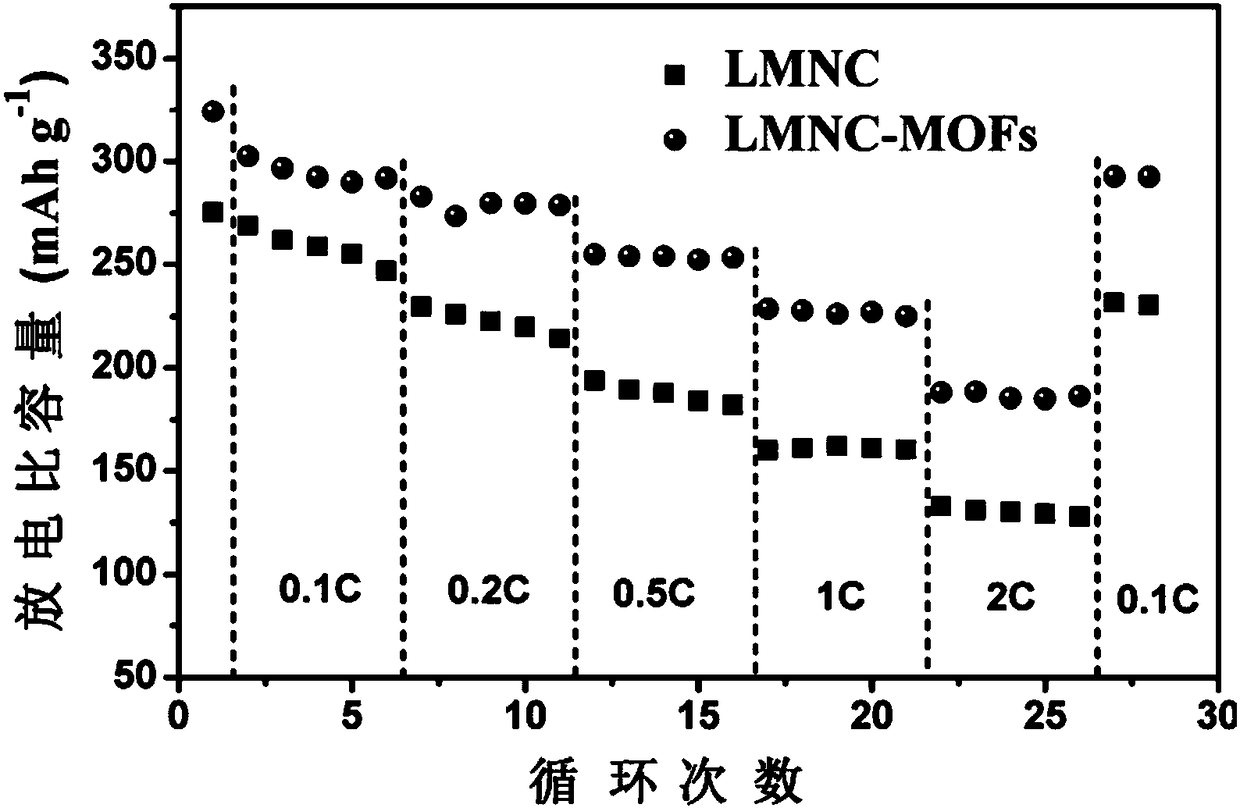

[0044] By XRD pattern ( figure 1 ) shows that the l...

Embodiment 2

[0049] Surface modification of MOFs applied to lithium-rich manganese materials Li 1.2 mn 0.6 Ni 0.2 o 2 , prepared by the following steps:

[0050] (1) Mix N,N-dimethylformamide, absolute ethanol and deionized water in a volume ratio of 13:2:2, add 0.12 manganese chloride and 0.13 g of 1,3,5-benzenetricarboxylic acid to obtain a mixed solution;

[0051] (2) Add 2 g of the lithium-rich positive electrode material to the mixed solution prepared in step (1), put it in a vacuum stirred reactor, and react at 120° C. for 1 h;

[0052] (3) The suspension obtained by the reaction is centrifuged and washed three times, and dried under vacuum to obtain a lithium-rich positive electrode material coated with MOFs;

[0053] (4) The MOFs-coated lithium-rich cathode material obtained in step (3) was placed in N 2 Sintering at 450 °C for 3 h under atmosphere to obtain MOFs-modified lithium-rich cathode materials.

Embodiment 3

[0055] Surface modification of MOFs applied to lithium-rich manganese materials Li 1.2 mn 0.6 Ni 0.2 o 2 , prepared by the following steps:

[0056] (1) Mix N,N-dimethylformamide, absolute ethanol and deionized water at 11:4:4, add 0.04g ferric chloride, 0.046g manganese chloride and 0.1g of 1,3,5 -benzenetricarboxylic acid obtains mixed solution;

[0057] (2) Add 2 g of the lithium-rich positive electrode material to the mixed solution prepared in step (1), put it into a vacuum stirred reactor, and react at 150° C. for 0.5 h;

[0058] (3) The suspension obtained by the reaction is centrifuged and washed three times, and dried under vacuum to obtain a lithium-rich positive electrode material coated with MOFs;

[0059] (4) The MOFs-coated lithium-rich cathode material obtained in step (3) was placed in N 2 Sintering at 600 °C for 2 h under atmosphere to obtain MOFs-modified lithium-rich cathode materials.

[0060] In summary, the present invention can stably prepare spin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com