A kind of titanium-based ceramics and its green preparation method

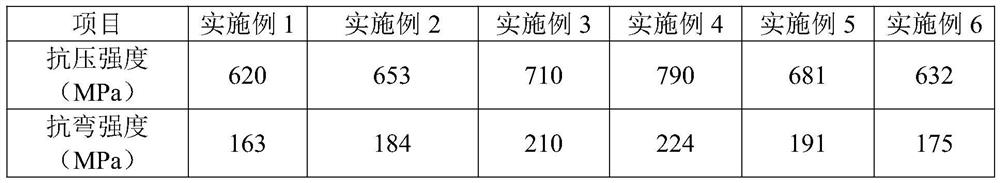

A ceramic and titanium-based technology, applied in the field of green preparation of titanium-based ceramics, can solve the problems of high bending strength less than 190MPa, secondary pollution, etc., to avoid secondary pollution, simple preparation process, and realize high value-added resources The effect of chemical utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of titanium-based ceramics:

[0029] (1) Wash the waste vanadium-titanium catalyst with 25wt% ammonia water, 3wt% nitric acid solution and water to remove surface-attached substances, dry at 100°C for 3h, and then place it in a muffle furnace for calcination at 300°C 3h, and finally crushed through a 150-mesh sieve to obtain vanadium-titanium-based denitration catalyst powder;

[0030] (2) 45 parts by mass of vanadium-titanium-based denitration catalyst powder and 0.8 parts by mass of ZrO 2 , 2.5 parts by mass of Al 2 o 3 , 0.1 parts by mass of Co 3 o 4 , 0.2 parts by mass of TiB 2 , 0.2 parts by mass of Nb 2 o 5 1. After mixing 5 parts by mass of CaO evenly, carry out wet ball milling. Ethanol is used as a solvent during wet ball milling. The wet ball milling time is 8 hours, then dried at 80° C. for 5 hours, and finally passed through a 100-mesh sieve to obtain a mixed powder;

[0031] (3) Add the mixed powder into the mold and hold the p...

Embodiment 2

[0033] Embodiment 2 Preparation of titanium-based ceramics:

[0034] (1) Wash the waste vanadium-titanium catalyst with 25wt% ammonia water, 3wt% nitric acid solution and water in order to remove the substances attached to the surface, dry it at 100°C for 3h, and then place it in a muffle furnace for calcination at 300°C 3h, and finally crushed through a 150-mesh sieve to obtain vanadium-titanium-based denitration catalyst powder;

[0035](2) 50 parts by mass of vanadium-titanium-based denitration catalyst powder and 1 part by mass of ZrO 2 , 3 parts by mass of Al 2 o 3 , 0.2 parts by mass of Co 3 o 4 , 0.5 parts by mass of TiB 2 , 0.5 parts by mass of B 2 o 3 , 8 parts by mass of CaO are mixed uniformly and then wet ball milled, using ethanol as a solvent during wet ball milling, the wet ball milling time is 10h, then dried at 80°C for 5h, and finally passed through a 100-mesh sieve to obtain a mixed powder;

[0036] (3) Add the mixed powder into the mold and hold the...

Embodiment 3

[0038] Example 3 Preparation of titanium-based ceramics:

[0039] (1) Wash the waste vanadium-titanium catalyst with 25wt% ammonia water, 3wt% nitric acid solution and water in order to remove the substances attached to the surface, dry it at 120°C for 1h, and then place it in a muffle furnace for calcination at 450°C 2h, and finally crushed through a 150-mesh sieve to obtain vanadium-titanium-based denitration catalyst powder;

[0040] (2) 80 mass parts of vanadium-titanium-based denitration catalyst powder and 6 mass parts of ZrO 2 , 10 parts by mass of Al 2 o 3 , 1.5 parts by mass of Co 3 o 4 , 1.5 parts by mass of TiB 2 , 1.2 parts by mass of CuO, and 15 parts by mass of CaO are mixed evenly and then wet ball milled. Ethanol or water is used as a solvent during wet ball milling. The wet ball milling time is 12h, then dried at 100°C for 3h, and finally passed through 100 mesh Sieve to obtain mixed powder;

[0041] (3) Add the mixed powder into the mold and hold the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com