Antibacterial capsaicin modified acrylic resin as well as preparation method and application thereof

A technology of acrylic resin and capsaicin, applied in coatings, biocide-containing paints, anti-fouling/underwater coatings, etc., can solve the problems of endangering the marine ecological environment and even human health, high efficiency, and long anti-fouling cycle. Achieve the effect of reducing attachment and reproduction ability, high reactivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

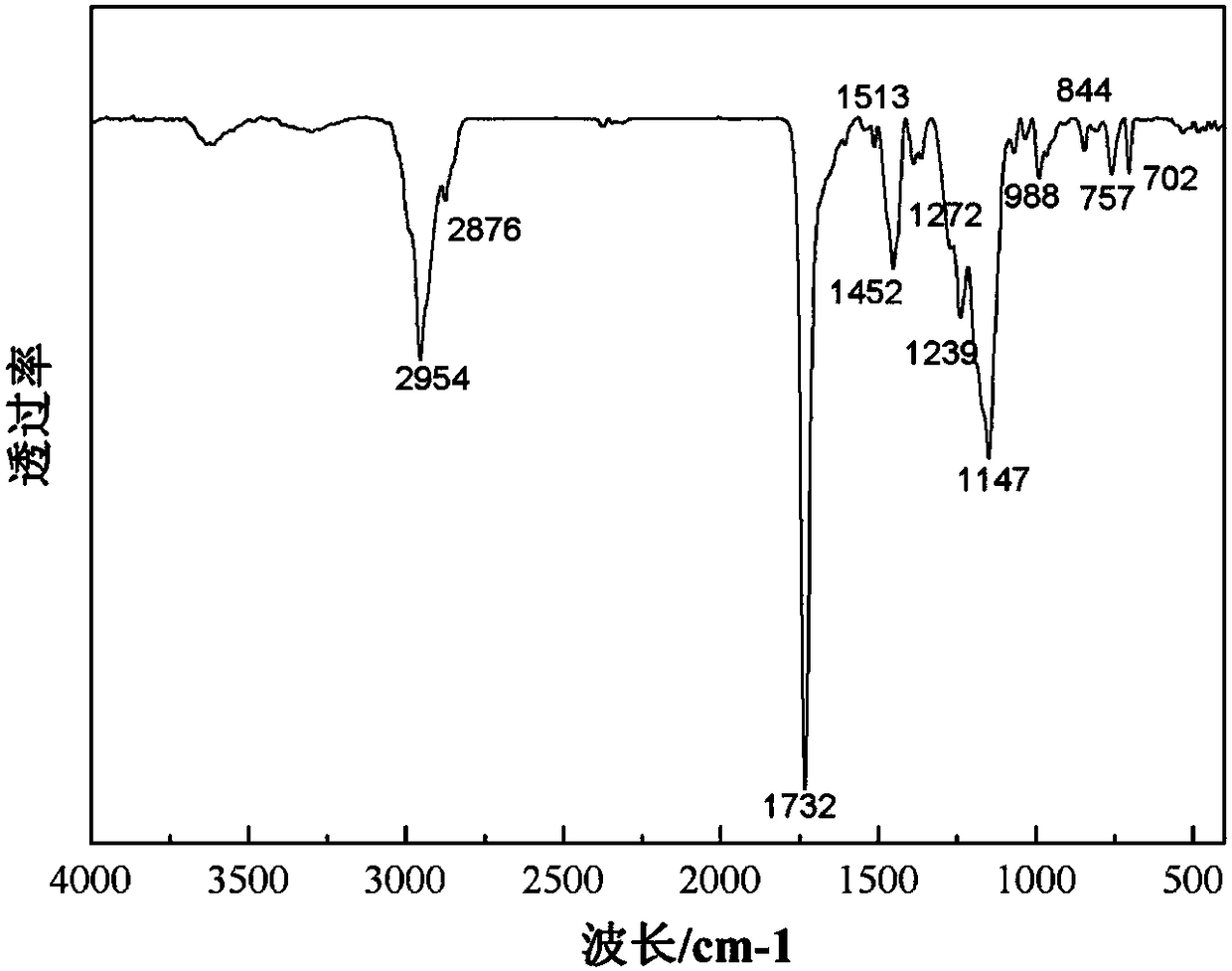

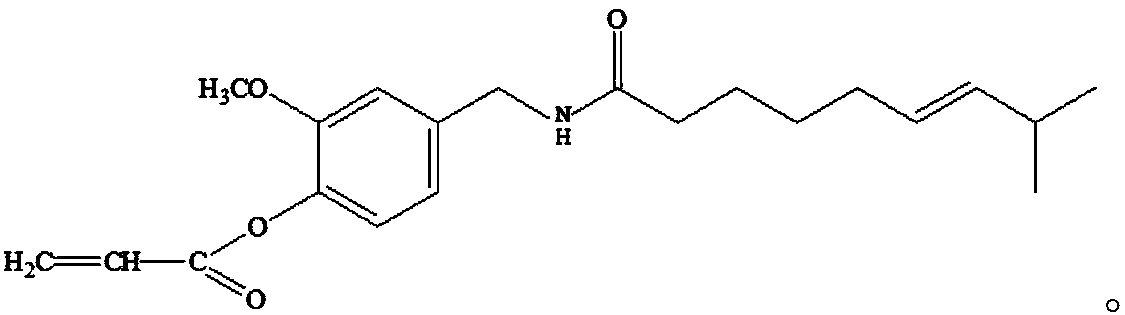

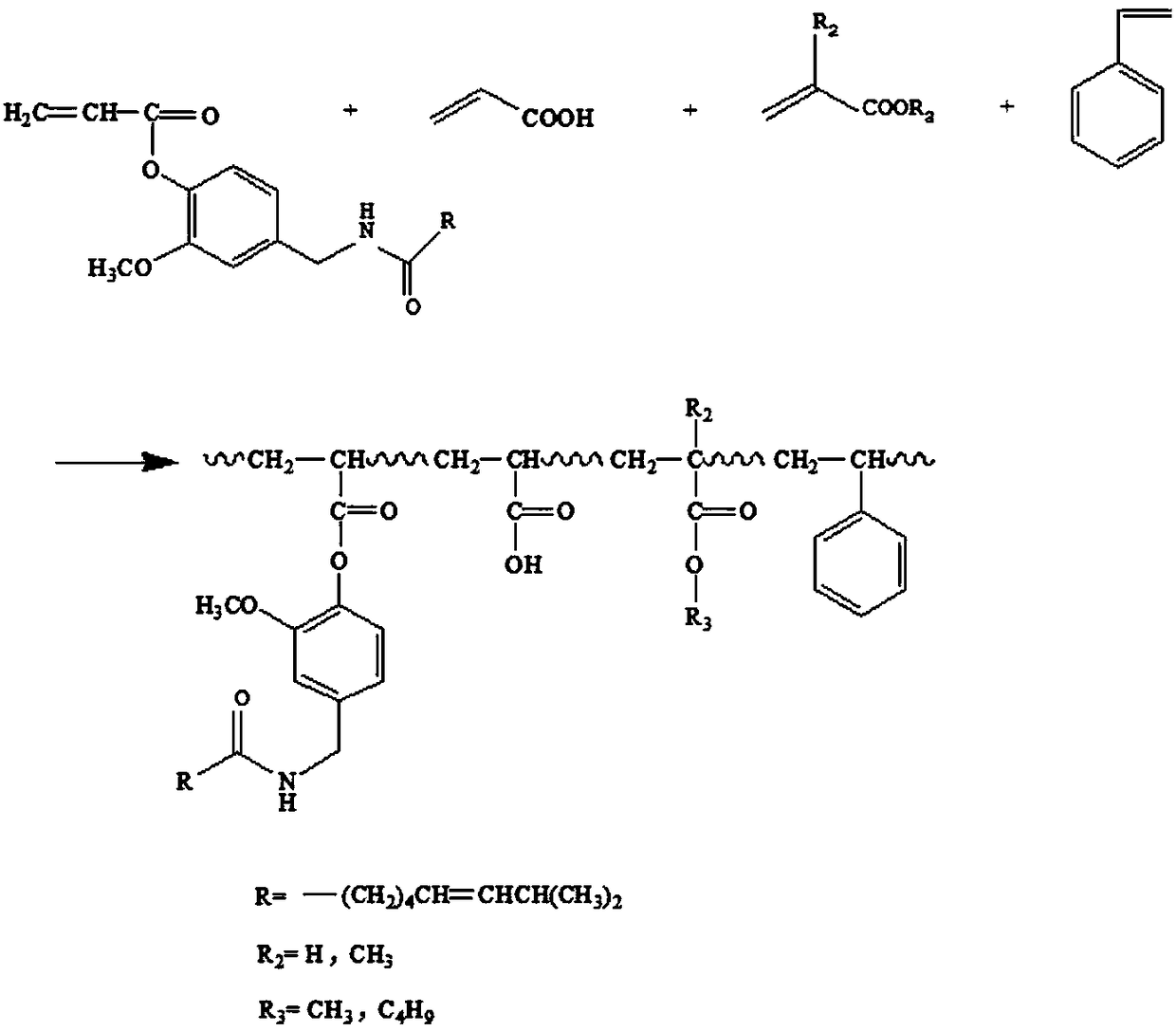

[0042] Antibacterial capsaicin-modified acrylic resin, the preparation steps are as follows: add 22g butyl acetate to a 250mL four-necked flask equipped with a condenser tube, a stirrer and a thermometer, heat up to 70°C while stirring, and the rotating speed is 200rpm. Add dropwise therein the butyl acetate that is dissolved with 3.5g capsaicin acrylate, 2g acrylic acid, 20g butyl acrylate, 25g methyl methacrylate, 3g styrene and 0.35g azobisisobutyronitrile (as solvent consumption is 20g ) solution, the dropping time is 3h. After dripping, keep warm for 2 hours, then add butyl acetate (4 g as a solvent) solution dissolved with 0.15 g of initiator (azobisisobutyronitrile), keep warm for 2 hours to prepare an acrylate polymer solution. Cool down to below 40°C and discharge. The resulting acrylate polymer solution was added to a large amount of methanol to obtain a solid acrylate polymer. The solution was formed into a film in an evaporating dish and dried for 7 days to obtai...

Embodiment 2

[0049] Antibacterial capsaicin-modified acrylic resin, the preparation steps are as follows: add 22g butyl acetate to a 250mL four-neck flask equipped with a condenser tube, a stirrer and a thermometer, heat up to 75°C while stirring, and the speed is 200rpm. Add dropwise therein the butyl acetate (20g) solution that dissolves 3.5g capsaicin acrylate, 1g acrylic acid, 20g butyl acrylate, 25g methyl methacrylate, 4g styrene and 0.18g azobisisobutyronitrile, drop Adding time is 3h. After dripping, keep warm for 2 hours, then add butyl acetate (4.25 g) solution dissolved with 0.07 g of initiator (azobisisobutyronitrile), keep warm for 3 hours, and obtain an acrylate polymer solution. Cool down to below 40°C and discharge. The resulting acrylate polymer solution was added to a large amount of methanol to obtain a solid acrylate polymer. The solution was formed into a film in an evaporating dish and dried for 7 days to obtain a polymer film.

[0050]The main performance characte...

Embodiment 3

[0056] Antibacterial capsaicin-modified acrylic resin, the preparation steps are as follows: add 22g butyl acetate in a 250mL four-neck flask equipped with a condenser, a stirrer and a thermometer, heat up to 80°C while stirring, and the rotation speed is 200rpm, with a peristaltic pump Add dropwise the butyl acetate (20g) solution that dissolves 2g capsaicin acrylate, 2g acrylic acid, 25g butyl acrylate, 21g methyl methacrylate, 3g styrene and 0.53g azobisisobutyronitrile, dropwise The time is 2h. After dripping, keep warm for 3 hours, then add butyl acetate (4.25 g) solution dissolved with 0.22 g of initiator (azobisisobutyronitrile), keep warm for 2 hours, and obtain an acrylate polymer solution. Cool down to below 40°C and discharge. The resulting acrylate polymer solution was added to a large amount of methanol to obtain a solid acrylate polymer. The solution was formed into a film in an evaporating dish and dried for 7 days to obtain a polymer film.

[0057] The main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com