Method for continuously producing diamond wires

A diamond wire and production method technology, applied in the direction of electrolytic coating, coating, etc., can solve the problems of unfavorable slicing and uneven number of diamonds, and achieve the effects of uniform rate, environmental protection, and avoiding inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

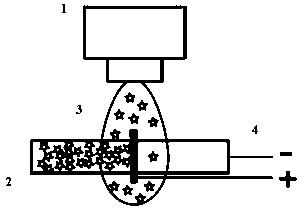

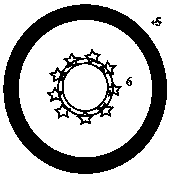

[0023] combine Figure 1-2 , The device in this embodiment includes a pump 1, a steel wire 2 and a power supply 4, and the steel wire 2 is connected to the negative pole of the power supply 4. Turn on the power to pass the current. The current passes through the ring-shaped nickel anode 5 and evenly reaches the cathode steel wire. At the same time, the anode nickel dissolves to form nickel ions that enter the electrolyte. The nickel ions in the electrolyte are reduced on the cathode surface of the steel wire to form an electroplated nickel layer, and at the same time, the diamond micropowder in the droplet is fixed on the steel wire, which is the process of pre-plating. The steel wire with diamond micropowder fixed on the surface enters the electroplating tank again for electroplating. There is no diamond micropowder in the electroplating bath of this electroplating tank, and only the nickel layer can be electroplated. The nickel layer around the diamond micropowder fixed o...

Embodiment 2

[0026] If you want to prepare diamond wire with thicker diamond thickness, there are two ways to get it: First, you can increase the diamond concentration in the pre-plating solution. Although this method is simple, it is impossible to increase the diamond concentration due to the limited diameter of the nozzle. The amplitude increases, which can exacerbate the possibility of nozzle clogging. In this case, the method of combined electroplating with dual nozzles can be used. As in the above embodiment, the diamond micropowder, nickel salt and boric acid of the same quality are weighed, and deionized water of the same quality is added to prepare a pre-plating solution. Heat the pre-plating solution to 45 o C, and add ultrasonic vibration. Connect the two nozzles into the pre-plating solution container respectively, start the two peristaltic pumps and wait for the two nozzles to enter a stable state respectively. Pass the two nickel ring anodes through the steel wire, and conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com