A kind of foliar fertilizer for increasing calcium content in rice grains and its preparation method and application

A technology of rice grain and foliar fertilizer, applied in application, organic fertilizer, fertilization device, etc., can solve the problems of complex operation, ineffective effect, high technical difficulty, etc., to increase calcium content, reduce spraying times, and accelerate decomposition The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

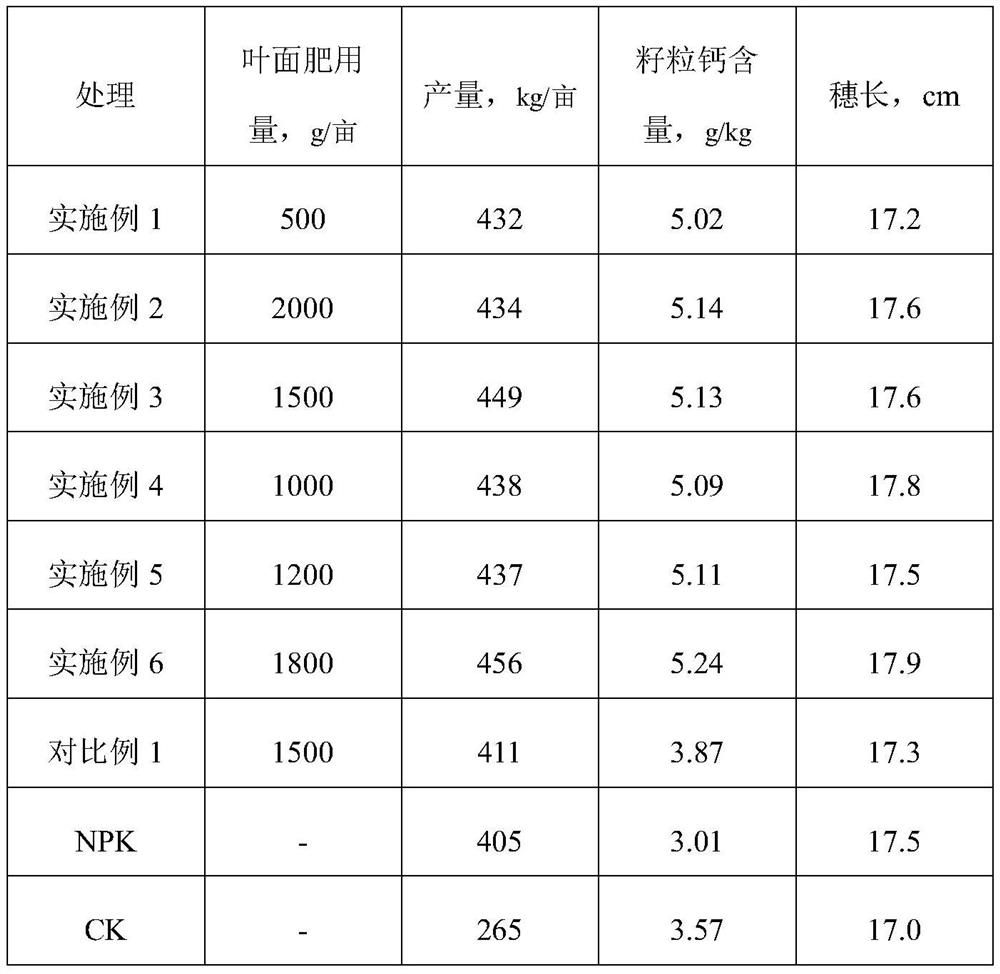

Examples

Embodiment 1

[0028] A foliar fertilizer for increasing calcium content in rice grains, comprising 100 g of calcium humate, 5 g of isoamyl acetate, and 895 g of water. Its preparation method comprises the following steps:

[0029] Preparation of calcium humate: crush 10kg of peanut stalks, mix them with 0.3kg of sepiolite powder and 1.5kg of lime based on the quality of the stalks, and mix with 0.1kg of EM bacteria solution, and adjust the C / N mass ratio to 30 with urea , mix well, adjust the water content to about 60wt%, and culture it under constant temperature and ventilation for 30 days under the condition of 30°C to obtain the decomposed product; air-dry the decomposed product, mix it with the extractant, calculate the decomposed product after air-drying, and extract The consumption of agent is 8mL / g, wherein the concentration of potassium citrate in the extractant is 0.03mol / L, the concentration of potassium hydroxide is 0.2mol / L, shakes 3h, leaves standstill 16h, then adds saturated ...

Embodiment 2

[0032] A foliar fertilizer for increasing calcium content in rice grains, comprising 150 g of calcium humate, 1 g of isoamyl acetate, and 849 g of water. Its preparation method comprises the following steps:

[0033] Preparation of calcium humate: crush 10kg of peanut stalks, mix them with 0.8kg of sepiolite powder and 1kg of lime based on the quality of the stalks, and mix with 0.2kg of EM bacteria liquid, adjust the C / N mass ratio to 20 with urea, Mix well, adjust the water content to about 70wt%, and cultivate at 30°C for 40 days with constant temperature and ventilation to obtain the decomposed product; air-dry the decomposed product, mix it with the extractant, and calculate the decomposed product after air drying, the extractant The dosage is 3mL / g, wherein the concentration of potassium maleate in the extractant is 0.08mol / L, the concentration of potassium hydroxide is 0.1mol / L, shaking for 12h, standing for 20h, then adding saturated sodium sulfate solution, the The a...

Embodiment 3

[0036] A foliar fertilizer for increasing calcium content in rice grains, comprising 120 g of calcium humate, 3 g of isoamyl acetate, and 877 g of water. Its preparation method comprises the following steps:

[0037] Preparation of calcium humate: crush 10kg of peanut stalks, and mix them with 0.5kg of sepiolite powder and 1.2kg of lime based on the quality of the stalks, 0.15kg of EM bacteria solution, and adjust the C / N mass ratio to 25 with urea , mix well, adjust the water content to about 65wt%, and culture it under constant temperature and ventilation for 35 days under the condition of 28°C to obtain the decomposed product; air-dry the decomposed product, mix it with the extractant, calculate the decomposed product after air-drying, and extract The consumption of agent is 5mL / g, wherein the concentration of potassium malate in the extractant is 0.05mol / L, the concentration of potassium hydroxide is 0.15mol / L, shakes 8h, leaves standstill 18h, then adds saturated sodium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com