Method for preparing semaglutide

A technology of semaglutide and a synthesis method, which is applied in the field of preparation of polypeptide drug semaglutide, can solve the problems of incomplete reaction, waste of raw materials and high production cost, and achieves improvement of purity and yield, reduction of racemic impurities, The effect of reducing the cost of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

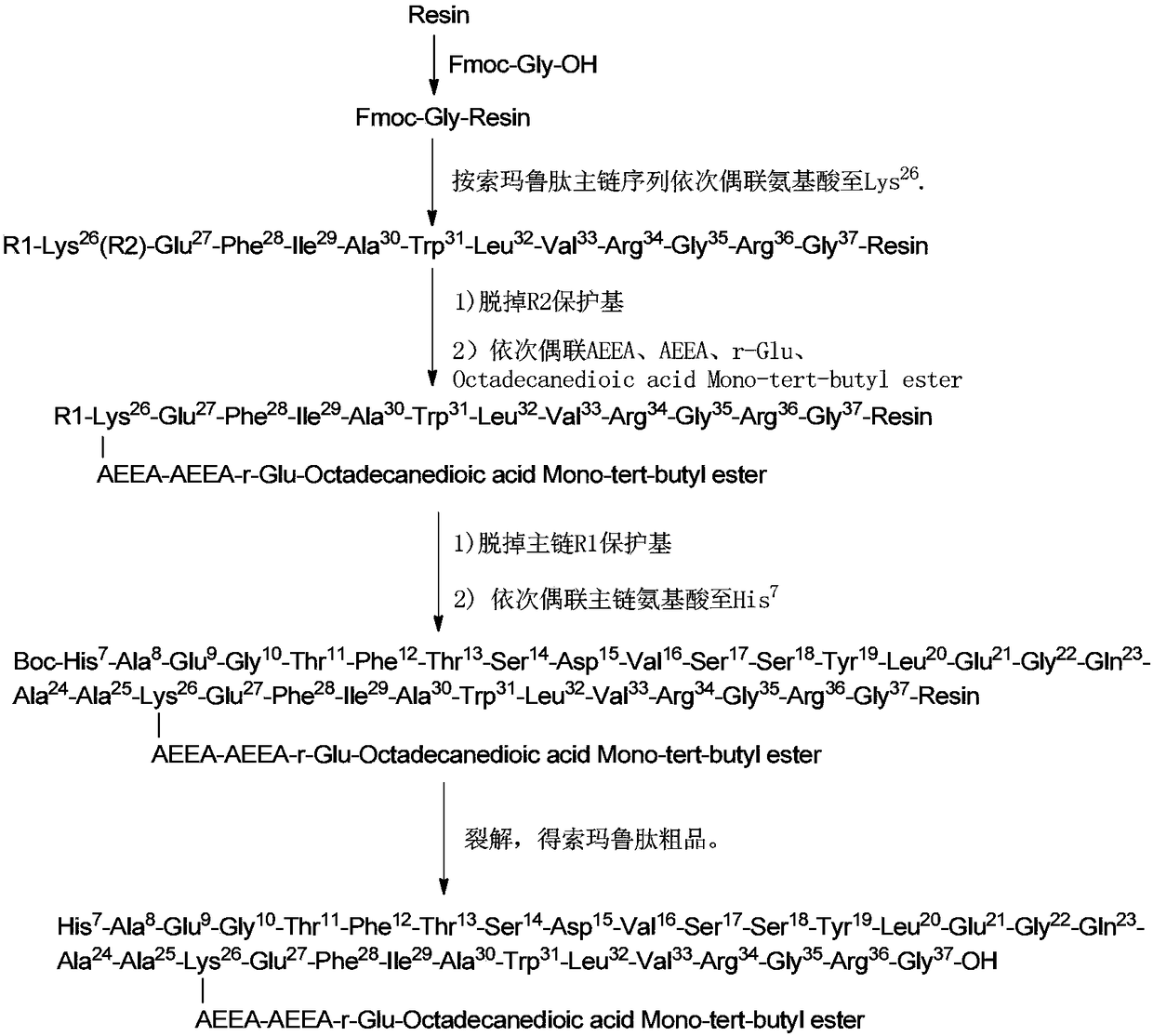

Method used

Image

Examples

Embodiment 1

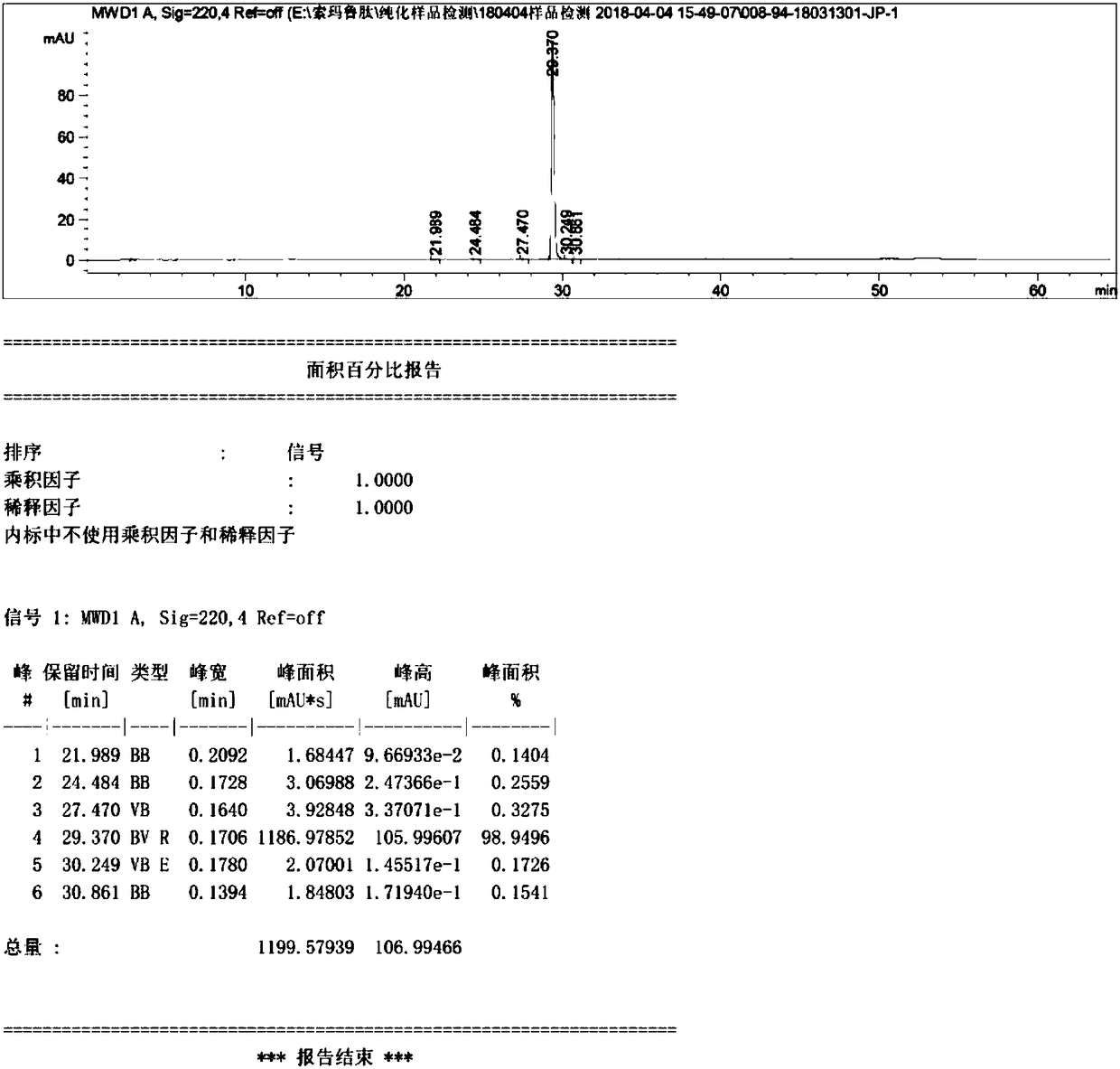

[0091] Embodiment 1, the preparation of semaglutide

[0092] (1) Preparation of Fmoc-Gly with a degree of substitution of 0.35mmol / g 37 -CTC

[0093] A. Add 50g (45mmol) of CTC Resin resin with a substitution degree of 0.9mmol / g into the reaction kettle, add 800ml of dichloromethane, mix for 2min, filter out the dichloromethane, then add 800ml of dichloromethane, mix for 40min, Dichloromethane was filtered off, and finally 800ml of dichloromethane was added, and after mixing for 2 minutes, dichloromethane was filtered off, and the resin was set aside.

[0094] B. Weigh 10.2g of Fmoc-Gly-OH in a beaker, add 800ml of dichloromethane and 7ml of DIEA, stir and activate the solution at 0-10°C for 5min, pour it into the CTC resin obtained in step A, and After mixing for 10 minutes at 20-25°C, add 20ml of DIEA and continue mixing for 50 minutes. After the reaction was completed, 50 ml of methanol was added, and the mixture was continued for 30 min. After the reaction, filter with...

Embodiment 2

[0128] Embodiment 2, the preparation of semaglutide

[0129](1) Preparation of Fmoc-Gly-Wang with a degree of substitution of 0.35mmol / g

[0130] A. Add 50g (45mmol) of Wang resin with a degree of substitution of 0.9mmol / g into the reactor, add 800ml of dichloromethane, mix for 2min, filter out the dichloromethane, then add 800ml of dichloromethane, mix for 40min, filter In addition to dichloromethane, finally add 800ml of dichloromethane, after mixing for 2min, filter out dichloromethane, and use the resin for later use.

[0131] B. Weigh 6.2g of Fmoc-Gly-OH and 3.2g of HOBT into a beaker, add 800ml of DMF and 37ml of DIEA, stir and activate the solution at 0-10°C for 5min, then pour it into the Wang resin obtained in step A, Add 7.5g of DMAP and mix for 2h at 20-25°C. After the reaction was completed, 20 ml of acetic anhydride was added, and the mixture was continued for 1 h. After the reaction, filter with suction, wash the resin 5 times with DMF, 800ml each time; after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com