Cellulose triacetate thin film and polarizer

A technology of cellulose triacetate and cellulose ester, which is applied in the direction of optics, optical components, polarizing components, etc., to achieve stable performance, better appearance and improved crystal point problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

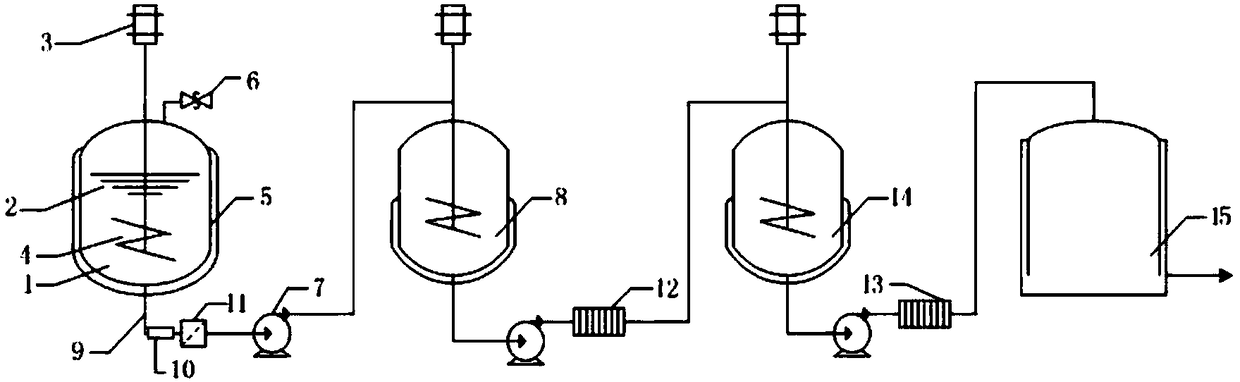

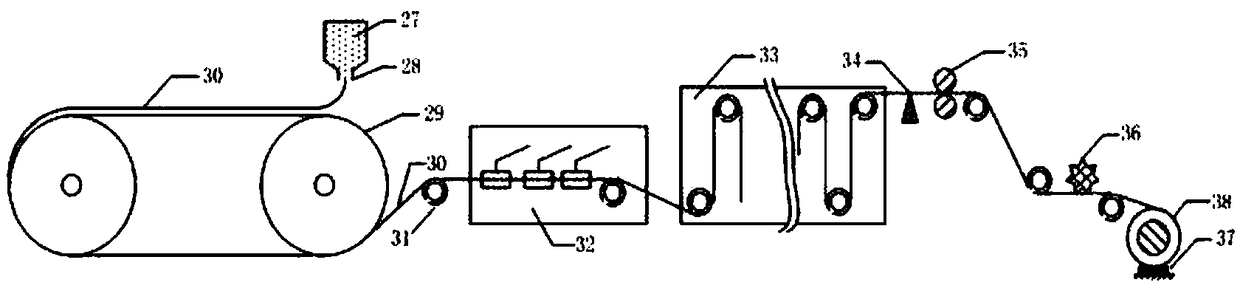

[0027] The preparation of cellulose triacetate film, including the steps of preparation of cotton glue solution, casting, drying and winding, will be described in detail below with reference to the accompanying drawings.

[0028] 1. If figure 1 Proceed to the preparation of the cotton glue solution as indicated.

[0029] Mix and dissolve

[0030] The accurately weighed organic solvent is prepared as a mixed solvent and sent to the mixing kettle 1. Mixed solvent comprises one or more in methylene chloride and methyl alcohol, ethanol, acetone, the mixed solvent of preferred methylene chloride and methyl alcohol of the present invention, the amount of mixed solvent is preferably accounted for 70-85% of cotton glue solution 27, further Preferably dichloromethane:methanol is 90:10.

[0031] Then, the cellulose triacetate particles are put into the mixing tank 1 , the amount of the cellulose triacetate particles is preferably 10-20% of the cotton gum solution 27 .

[0032] Then,...

Embodiment 1

[0063] like figure 1 As shown, in the mixing tank 1, 70% by weight of mixed solvent, 20% by weight of cellulose triacetate particles, 7% by weight of TPP and BDP plasticizer mixture, 2.99% by weight of UV928 and UV329 UV absorber mixture. Stir the above mixture at a constant speed for 20 minutes to obtain the initially dissolved cotton glue solution 2, heat the cotton glue solution 2 at 80°C and pressurize at 0.5MPa for 10 minutes, drop to normal temperature and pressure and continue to dissolve for 20 minutes. The control temperature of the cotton glue solution 2 transported by the pipeline 9 is 32° C., and the temperature difference is 0-0.5° C. The cotton glue solution 2 is filtered three times and then enters the thermostat 15 to stand still for defoaming, and then transported to the front end of the casting nozzle 28 to be mixed with the matting agent dispersion 17.

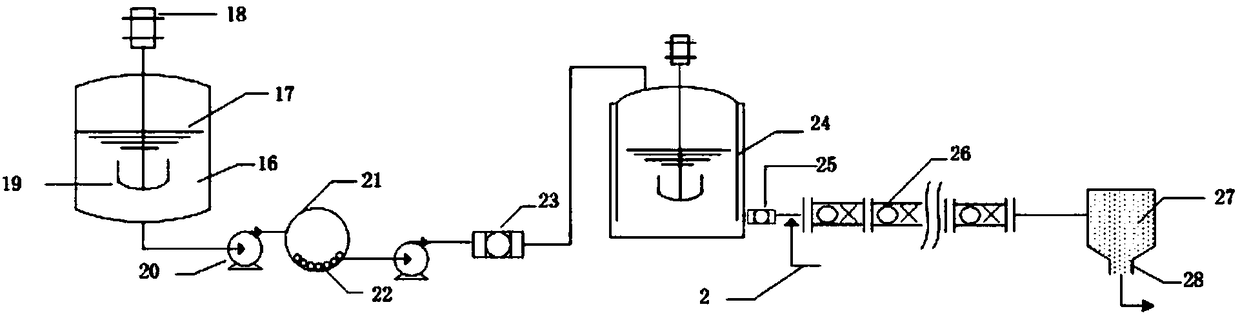

[0064] like figure 2 As shown, a small amount of cotton glue solution 2 and a mixed solvent are put i...

Embodiment 2

[0067] The TAC film preparation process is as in implementation 1, the difference is that in the mixing tank 1, drop into 75% by weight of the mixed solvent, drop into 15% by weight of cellulose triacetate particles, 5.95% by weight of TPP and BDP for plasticization Agent mixture, 4% by weight of UV928 and UV329 UV absorber mixture. Heat the initially dissolved cotton glue solution 2 at 90° C. and pressurize at 0.3 MPa for 20 minutes. The temperature of the cotton glue solution 2 in the delivery pipeline 9 is controlled to be 34°C, and the temperature difference is 0-0.3°C.

[0068] The specific surface area is 110m 2 / g of R972 is added to the diluted cotton glue solution to make dispersion 17, and is sent to dispersion device 21 (sand mill), and the matting agent in dispersion 17 is dispersed into an average particle diameter of 0.6 micron, and the dispersion The liquid a filter 23 filters the dispersion liquid 17, and the particles of the dispersion liquid matte agent with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com