Feeding and treating apparatus for raw material of methane tank

A biogas digester raw material and processing device technology, applied in the direction of biomass post-treatment, biomass pre-treatment, biochemical cleaning device, etc., can solve the problems of high raw material requirements, inconvenient use, etc., and achieve the effect of ensuring a closed environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

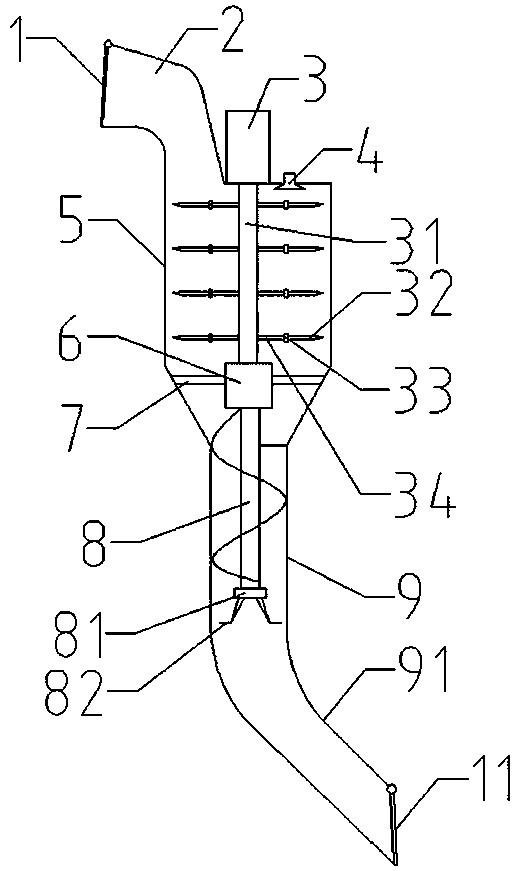

[0021] Such as figure 1 As shown, a biogas digester raw material feeding treatment device includes a feed nozzle 2, a crusher, a gearbox 6, a screw conveyor and a feed pipe 91, the feed nozzle 2 is a curved trumpet shape, and the screw conveyor includes a screw The auger 8 and the cover body 9, the breaker includes a drive motor 3, a rotating column 31, a cutting blade and a casing 5, the lower end of the feed nozzle 2 is arranged on one side of the upper end of the casing 5, and the drive motor 3 is arranged at the center of the upper end of the casing 5, The upper end of casing 5 is also provided with a liquid nozzle 4, and rotating column 31 is vertically arranged in casing 5 and the output shaft of upper end connection drive motor 3, and rotating column 31 is provided with four layers of cutting blades from top to bottom, each layer There are three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com