A display panel, its manufacturing method and display device

A display panel and encapsulation layer technology, which is applied in the field of display panel, display device, and its preparation, can solve problems such as rising cost, reduced device life, and reduced production efficiency, so as to improve density, increase production efficiency, and reduce the number of film layers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

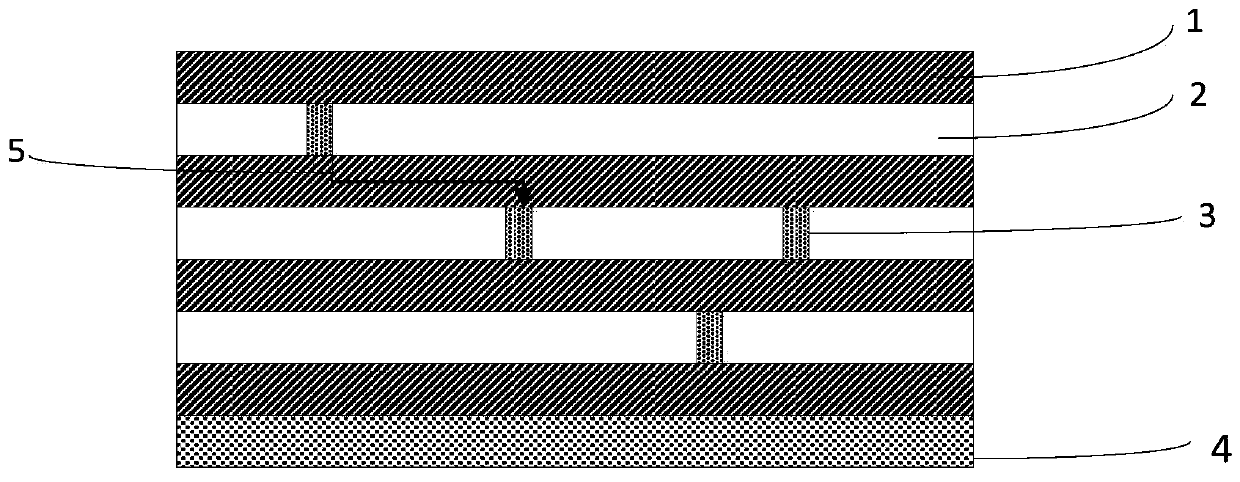

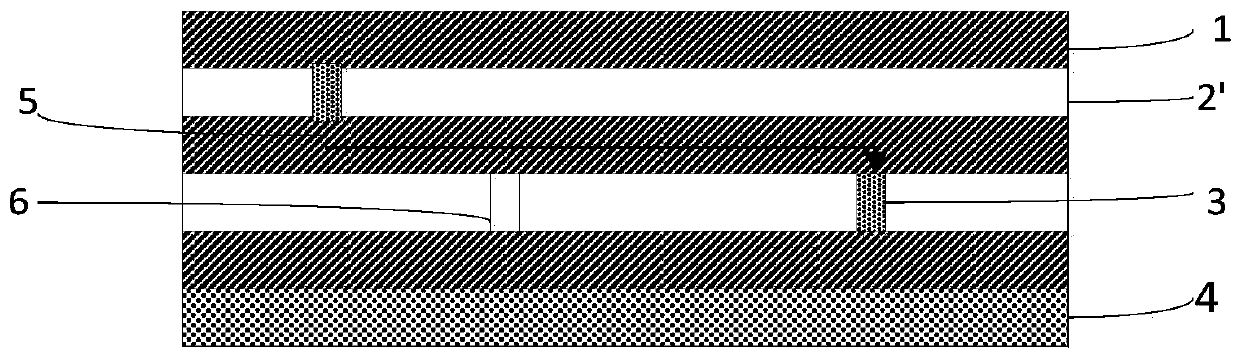

[0050] The embodiment of the present invention also provides a method for preparing a display panel, including forming an encapsulation layer covering the display substrate, the encapsulation layer including an inorganic composite film layer, and the step of forming the inorganic composite film layer includes:

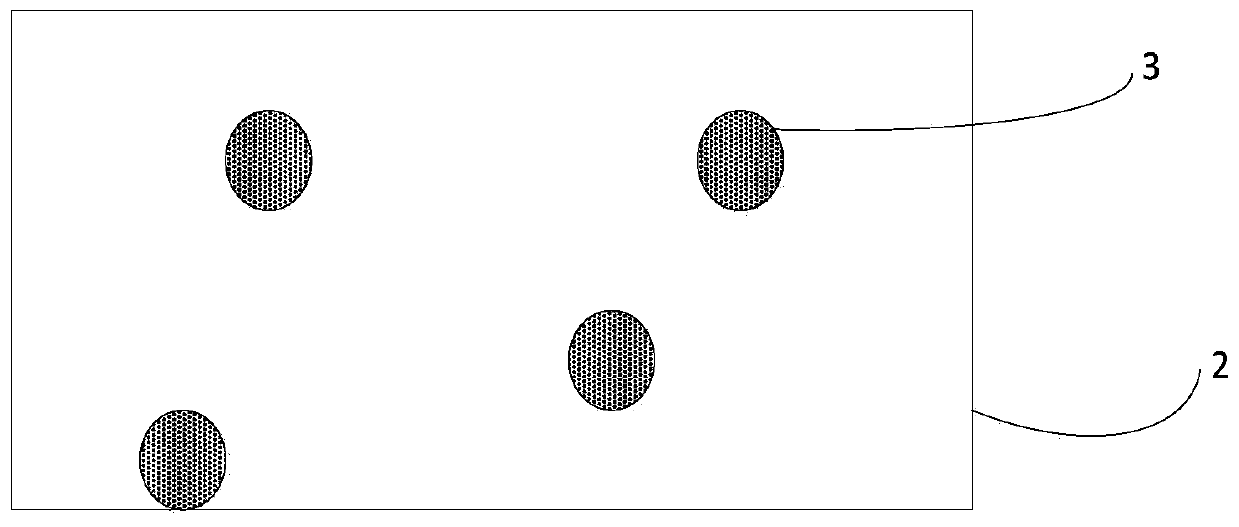

[0051] forming an inorganic matrix, the inorganic matrix comprising a plurality of crystal grains with voids between the crystal grains;

[0052] Spray the slurry on the inorganic matrix, the slurry gradually penetrates into the inorganic matrix, and after heating to remove the solvent in the slurry, an inorganic filler that wraps the crystal grains and fills the gaps is formed , the inorganic matrix and the inorganic filler together constitute an inorganic composite membrane.

[0053] According to the present invention, the encapsulation layer also includes an organic film layer, and the method for forming the encapsulation layer is:

[0054] Alternately forming orga...

Embodiment 1

[0079] Step S1: forming an organic film layer;

[0080] Step S2: forming a silicon nitride inorganic matrix on the organic film layer;

[0081] Preparation of 12%BaO-16%B 2 o 3 -9%Al 2 o 3 -63%SiO2 2 Glass sol, respectively select the highly active precursors of the target product, barium acetate, boric acid, aluminum nitrate nonahydrate, and ethyl silicate, and dissolve them in their respective organic solvents, such as glacial acetic acid, alcohol, etc., and mix them in a certain order to form a sol , and then add diethylenetriamine to the sol to form a gel, spray the prepared gel evenly on the surface of the inorganic substrate, heat it in the range of 280-340°C, and after the solvent evaporates, the slurry of the glass component in the amorphous state The material will fill the gaps in the film layer to form an inorganic composite film layer.

[0082] Step S3: forming an organic film layer on the inorganic composite film layer;

[0083] Repeat step S2 and step S3 un...

Embodiment 2

[0085] Step S1: forming an organic film layer;

[0086] Step S2: forming a silicon nitride inorganic matrix on the organic film layer;

[0087] Preparation of 8%CaO-8%MgO-17%Al 2 o 3 -67% SiO2 2 For glass sol, the highly active precursors of the target product, calcium nitrate tetrahydrate, magnesium nitrate hexahydrate, aluminum nitrate nonahydrate, and ethyl silicate, are also selected and dissolved in their respective organic solvents, and added in a certain order to form a sol, and then added to the sol Diethylenetriamine is added to form a gel, and the prepared gel is evenly sprayed on the surface of the inorganic substrate, and heated in the range of 280-340°C. After the solvent evaporates, the slurry of the amorphous glass component will adhere to the film. The gaps in the layer are filled to form an inorganic composite film layer.

[0088] Step S3: forming an organic film layer on the inorganic composite film layer;

[0089] Repeat step S2 and step S3 until at lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com