Mask-based zonal preheating apparatus and zonal preheating method thereof

A mask and equipment technology, applied in the field of rapid manufacturing equipment, can solve the problems of reduced working time and long-term working stability of molding machines, can not be recycled and reused, and narrow preheating range, etc., to increase working stability and continuous The effect of reducing working hours, reducing aging and hardening, and reducing equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

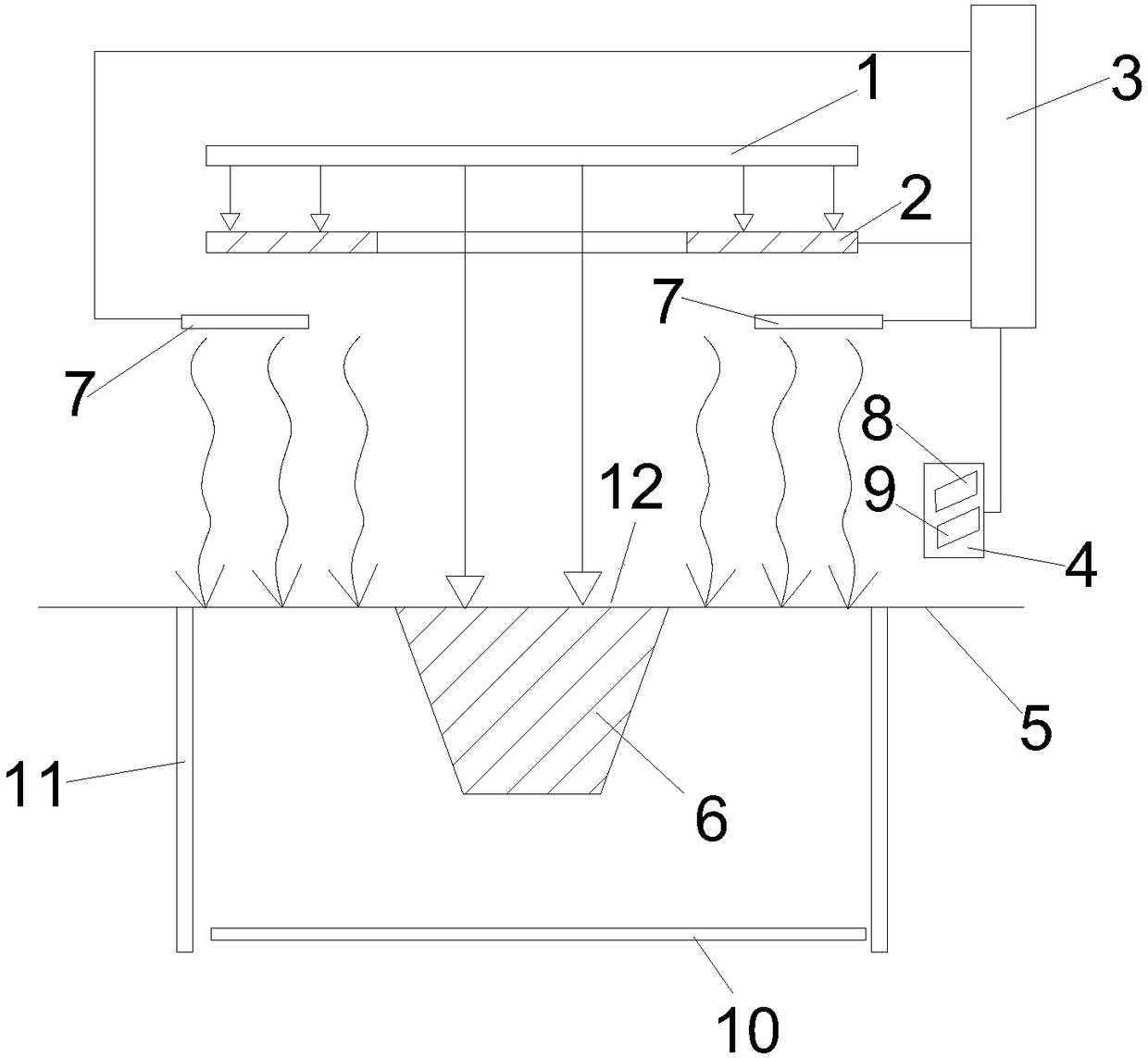

[0031] Such as figure 1 As shown, the mask-based partition preheating equipment provided by the present invention includes a molding cylinder 11 arranged at the bottom, and the bottom of the molding cylinder 11 is provided with a heating substrate 10 for heating the bottom powder. The cross-sectional profile is provided with a local preheating zone 12, the local preheating zone 12 is coated with the powder to be sintered 5 coated by the powder feeding mechanism, and the powder 5 is accumulated in the forming cylinder 11 to form a powder bed. In the embodiment, the high-melting point series polymer HP3PEEK powder introduced by the German EOS company is taken as an example to describe in detail. Among them, the melting point of HP3PEEK powder is 372°C. When the traditional global single preheating method is adopted, the preheating temperature of the powder surface is 365°C, the forming substrate is 340°C, and the temperature of the four walls of the forming cylinder 11 is 345°C;...

Embodiment 2

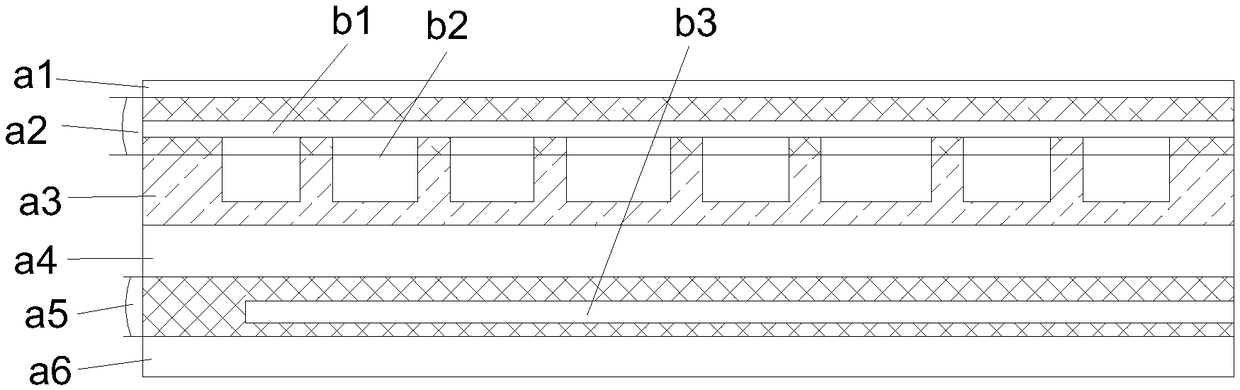

[0050] Such as figure 2 As shown, this embodiment has been further improved on the basis of Embodiment 1. The difference is that in this embodiment, a layered structure is provided under the mask plate 2, and the layered structure includes setting heat in an up-and-down order. The reflective layer a1, the first heat dissipation layer a2, the second heat dissipation layer a3, the heat insulation layer a4, the third heat dissipation layer a5 and the fixed layer a6, wherein the heat reflection layer a1 is made of a material with a high degree of smoothness. Made of light stainless steel. The fixed layer a6 is made of hard ceramic material, and then the bottom surface is bonded with heat-resistant resin and the top plate 10 of the molding cylinder. Preferably, the heat insulation layer a4 is made of asbestos material, which plays the role of heat insulation and heat resistance. The first heat dissipation layer a2 is made of coarse-grained sand material and made of pottery mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com