UV printing ink, and preparation method thereof

An ink and urethane acrylate technology, applied in the field of UV ink and its preparation, can solve the problems of ink adhesion, water resistance, wine resistance, poor weather resistance, inability to achieve instant curing, human health hazards, etc., and achieve no irritation. The effect of smell, low production cost and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

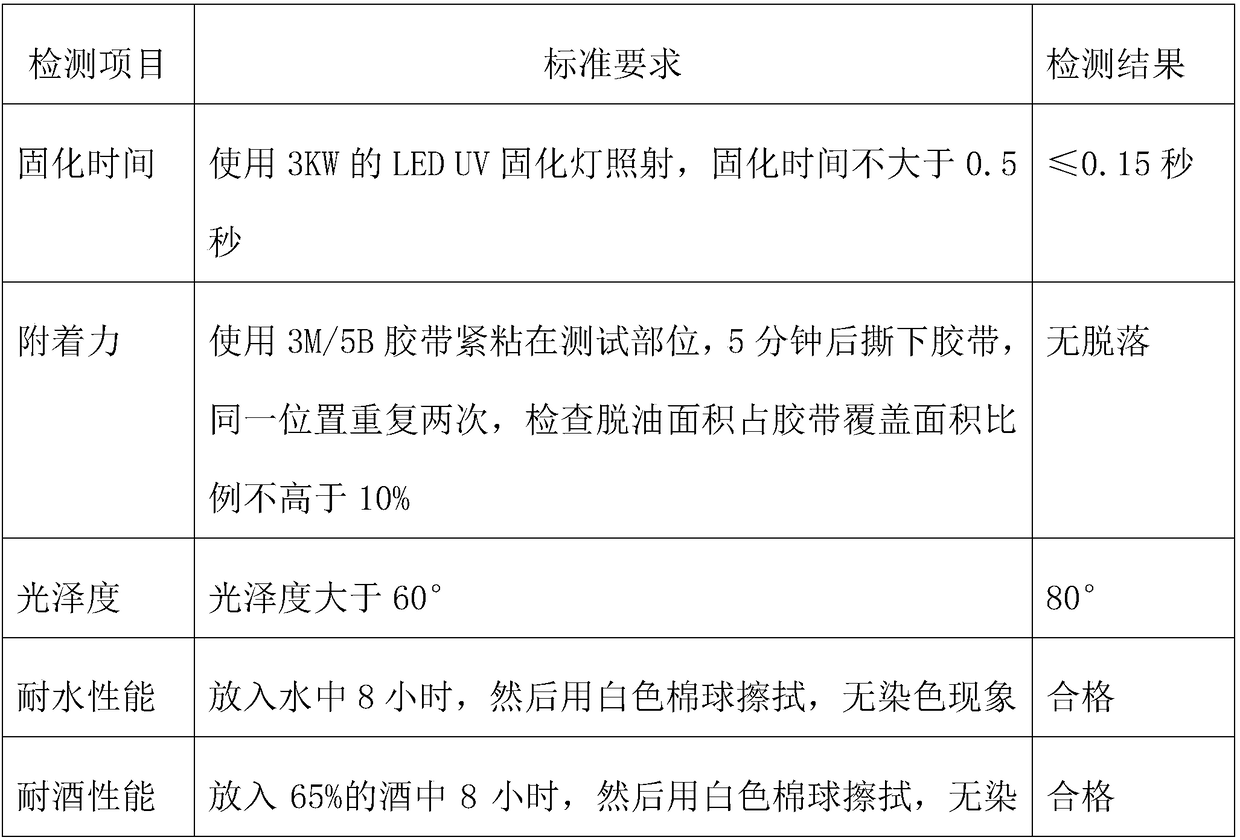

Embodiment 1

[0025] Embodiment 1 of the present invention provides a UV ink, which is mainly made of the following components in parts by weight: 40 parts of polyurethane acrylate, 10 parts of epoxy acrylate, 20 parts of alkoxy acrylate, benzophenone 2 parts, 2 parts of triethanolamine, 2 parts of polyethylene wax, 5 parts of pigment, 2 parts of bentonite.

[0026] The preparation method of this UV printing ink is as follows:

[0027] S1: Add urethane acrylate, epoxy acrylate, polyethylene wax and alkoxy acrylate into the first dispersion tank according to the above weight parts for pre-dispersion;

[0028] S2: Add the pigment into the second dispersion tank for pre-dispersion, then use the first grinder to grind the dispersed pigment, and add the ground pigment into the first dispersion tank according to the above weight portion;

[0029] S3: sequentially add benzophenone, triethanolamine and bentonite to the first dispersing tank according to the above weight parts, then heat the soluti...

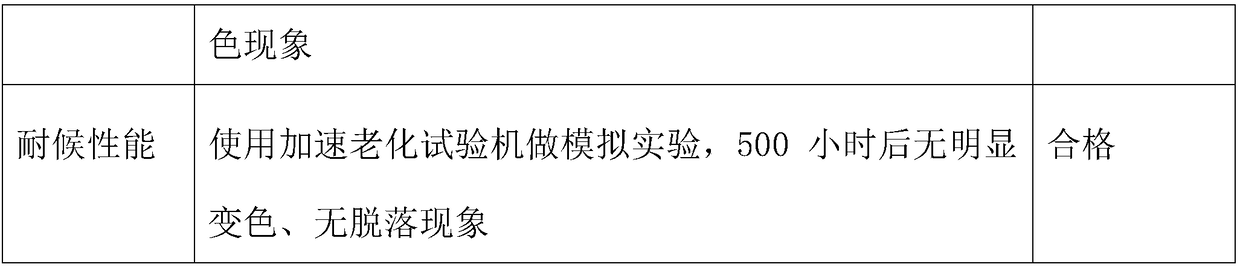

Embodiment 2

[0037] Embodiment 2 of the present invention provides a UV ink, which is mainly made of the following components in parts by weight: 55 parts of polyurethane acrylate, 5 parts of epoxy acrylate, 20 parts of trimethylolpropane triacrylate, two 5 parts of benzophenone, 5 parts of triethanolamine, 4 parts of polyethylene wax, 10 parts of pigment, 3 parts of bentonite.

[0038] The preparation method of this UV printing ink is as follows:

[0039] S1: Add urethane acrylate, epoxy acrylate, polyethylene wax and trimethylolpropane triacrylate to the first dispersion cylinder in the above weight parts for pre-dispersion;

[0040] S2: Add the pigment into the second dispersion tank for pre-dispersion, then use the first grinder to grind the dispersed pigment, and add the ground pigment into the first dispersion tank according to the above weight portion;

[0041] S3: sequentially add benzophenone, triethanolamine and bentonite to the first dispersing tank according to the above weigh...

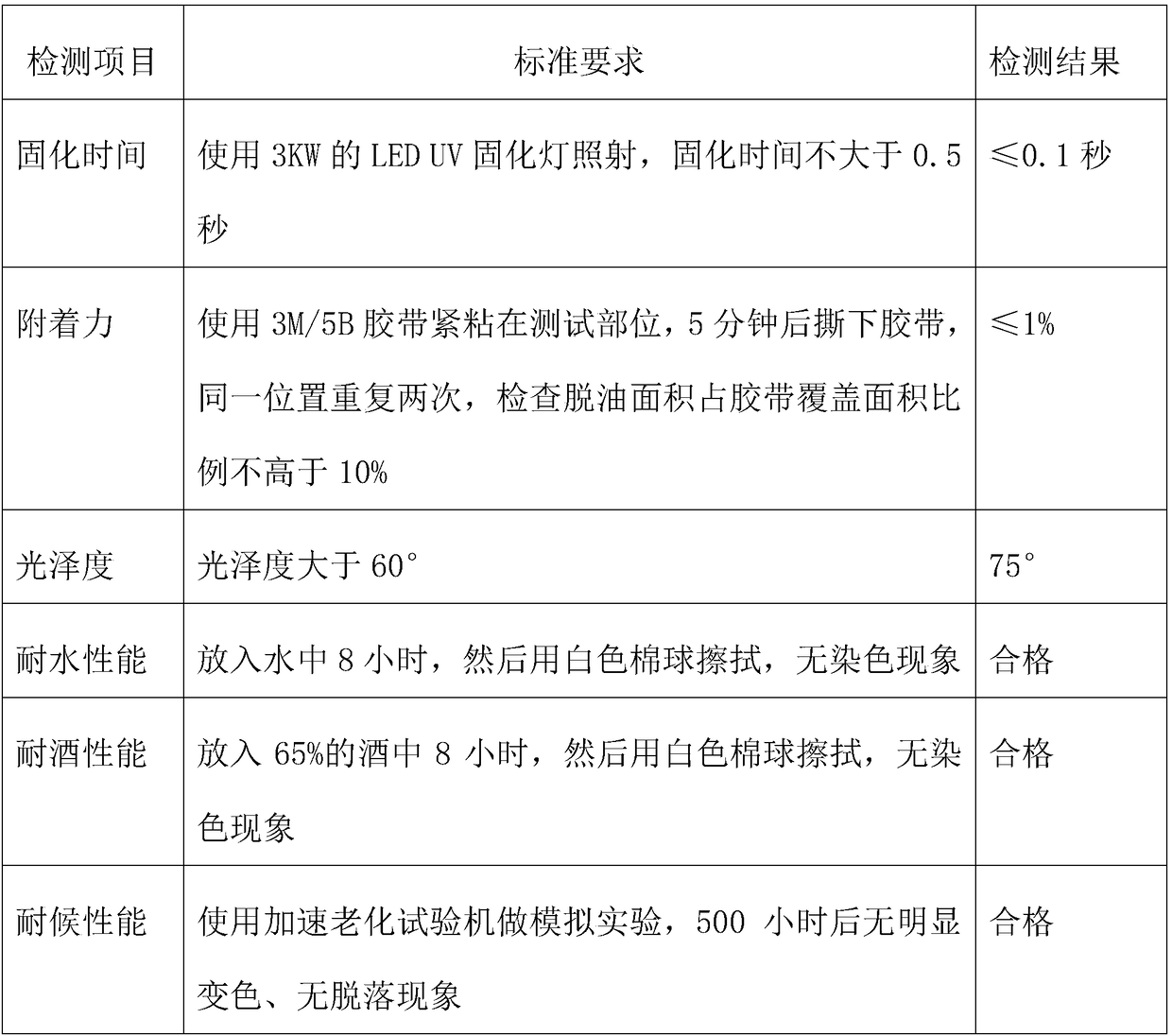

Embodiment 3

[0048] Embodiment 3 of the present invention provides a UV ink, which is mainly made of the following components in parts by weight: 45 parts of polyurethane acrylate, 8 parts of epoxy acrylate, 25 parts of hexanediol diacrylate, diphenylmethane 3 parts of ketone, 3 parts of triethanolamine, 3 parts of polyethylene wax, 8 parts of pigment, 2 parts of bentonite.

[0049] The preparation method of this UV printing ink is as follows:

[0050] S1: Add urethane acrylate, epoxy acrylate, polyethylene wax and hexanediol diacrylate into the first dispersion tank according to the above weight parts for pre-dispersion;

[0051] S2: Add the pigment into the second dispersion tank for pre-dispersion, then use the first grinder to grind the dispersed pigment, and add the ground pigment into the first dispersion tank according to the above weight portion;

[0052] S3: sequentially add benzophenone, triethanolamine and bentonite to the first dispersing tank according to the above weight par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com