A kind of porous ges single crystal nano sheet and preparation method thereof

A single crystal nano, silicon wafer technology, applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problem that the battery has not made obvious progress, to reduce the difficulty of preparation, ensure the integrity, increase the The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of porous GeS single crystal nanosheets, comprising the following steps:

[0029] (1) Place silicon wafers with a thickness of 500 μm and a width of 3 mm in acetone and isopropanol in sequence, ultrasonically clean them for 5 minutes, then dry them with high-purity nitrogen, and place them 12 to 15 cm downstream of the center of the tube furnace ;

[0030] (2) Place the quartz boat containing 10mgGeS powder in the center of the quartz tube, then evacuate to a background vacuum of 100mTorr, then flush with high-purity argon gas for 3 times, and then feed argon gas at a rate of 30sccm until The pressure is kept at 40Torr;

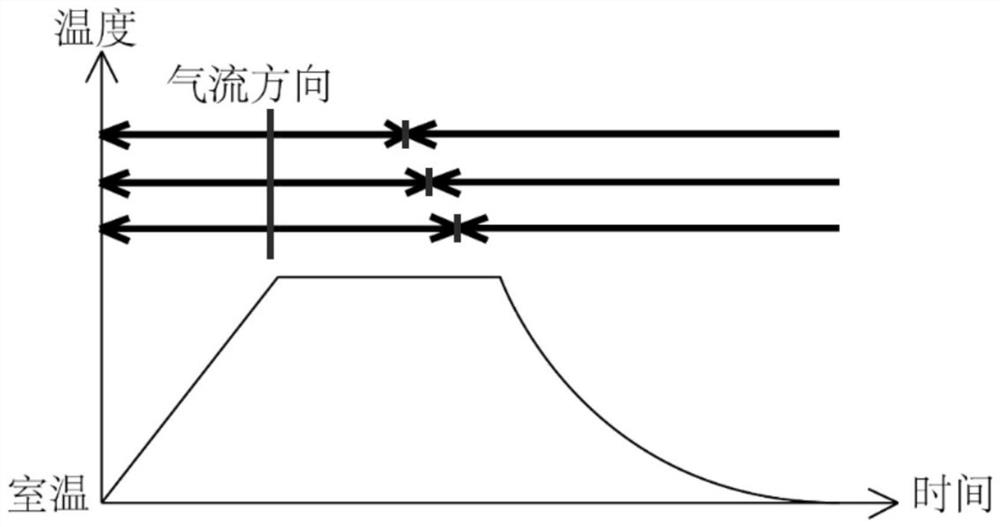

[0031] (3) After the pressure in the quartz tube is stabilized, the temperature of the tube furnace is raised at a rate of 50°C / min. In the opposite direction, refer to figure 1 ), to prevent the deposition of GeS powder in the heating process;

[0032] (4) When the deposition temperatures of the GeS powder and the substrate ri...

Embodiment 2

[0036] A preparation method of porous GeS single crystal nanosheets, comprising the following steps:

[0037] (1) Place silicon wafers with a thickness of 500 μm and a width of 3 mm in acetone and isopropanol in sequence, ultrasonically clean them for 5 minutes, then dry them with high-purity nitrogen, and place them 12 to 15 cm downstream of the center of the tube furnace ;

[0038] (2) Place the quartz boat containing 10mgGeS powder in the center of the quartz tube, then evacuate to a background vacuum of 80mTorr, then flush with high-purity argon gas for 3 times, and then feed argon gas at a rate of 10sccm until The pressure is kept at 20Torr;

[0039] (3) After the pressure in the quartz tube is stabilized, the temperature of the tube furnace is raised at a rate of 60°C / min. in the opposite direction) to prevent the deposition of GeS powder during the heating process;

[0040] (4) When the deposition temperatures of the GeS powder and the substrate rise to 500°C and 330...

Embodiment 3

[0044] A preparation method of porous GeS single crystal nanosheets, comprising the following steps:

[0045] (1) Place silicon wafers with a thickness of 500 μm and a width of 3 mm in acetone and isopropanol in sequence, ultrasonically clean them for 5 minutes, then dry them with high-purity nitrogen, and place them 12 to 15 cm downstream of the center of the tube furnace ;

[0046] (2) Place the quartz boat containing 10mgGeS powder in the center of the quartz tube, then evacuate to a background vacuum of 90mTorr, then flush it with high-purity argon gas for 3 times, and then feed argon gas at a rate of 15sccm until The pressure is kept at 22Torr;

[0047] (3) After the pressure in the quartz tube is stabilized, the tube furnace is heated up at a rate of 58°C / min. During the temperature rise process, the flow direction of the argon gas introduced is reversed (that is, it is different from the flow direction during the deposition. in the opposite direction) to prevent the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com