Orthogonal volume holographic grating solid-state laser

A technology of solid-state lasers and volume holographic gratings, which is applied to lasers, laser components, laser components, etc., can solve problems such as complex optical paths, and achieve the effect of power increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

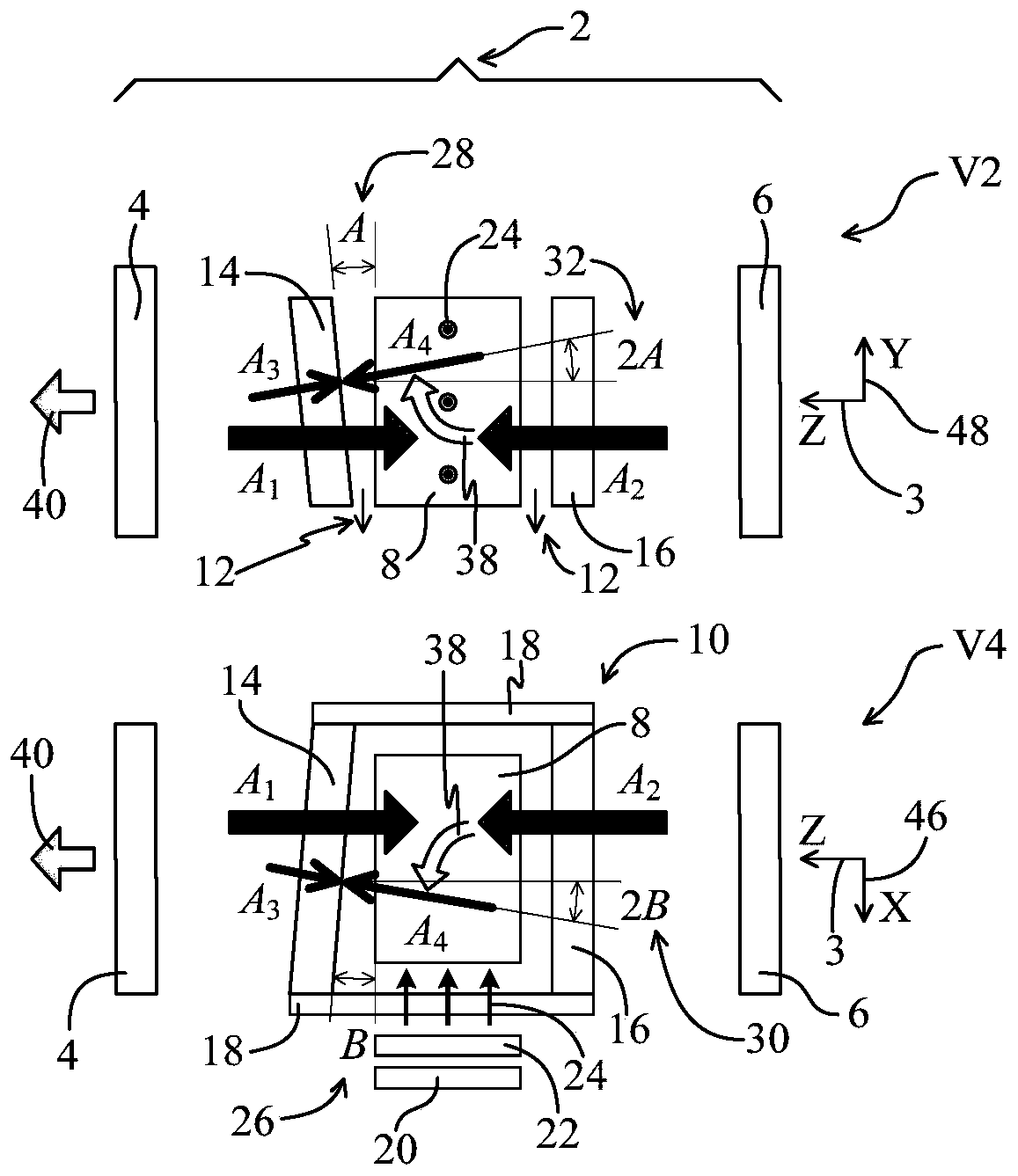

[0026] like figure 1As shown, it is a schematic structural diagram of a single-side pumping mode of an orthogonal volume holographic grating solid-state laser according to an embodiment of the present invention, including a V2 plane view of the Y-Z plane and a V4 plane view of the X-Z plane. The orthogonal volume holographic grating solid-state laser includes a laser resonant cavity 2 , an activation element 8 and a pumping source 20 . The laser resonator 2 is a linear resonator, using parallel planar cavities. Non-parallel planar cavities, or other cavity types can also be used. One reason for using non-parallel planar cavities is to compensate for the additional optical path inside the active element 8 due to one-sided pumping. The laser resonator 2 includes an output mirror 4 and a high reflection mirror 6 which are oppositely arranged. A strip-shaped activation element 8 in the shape of a cuboid is arranged in the laser resonator 2 . The activation element 8 is arrange...

Embodiment 2

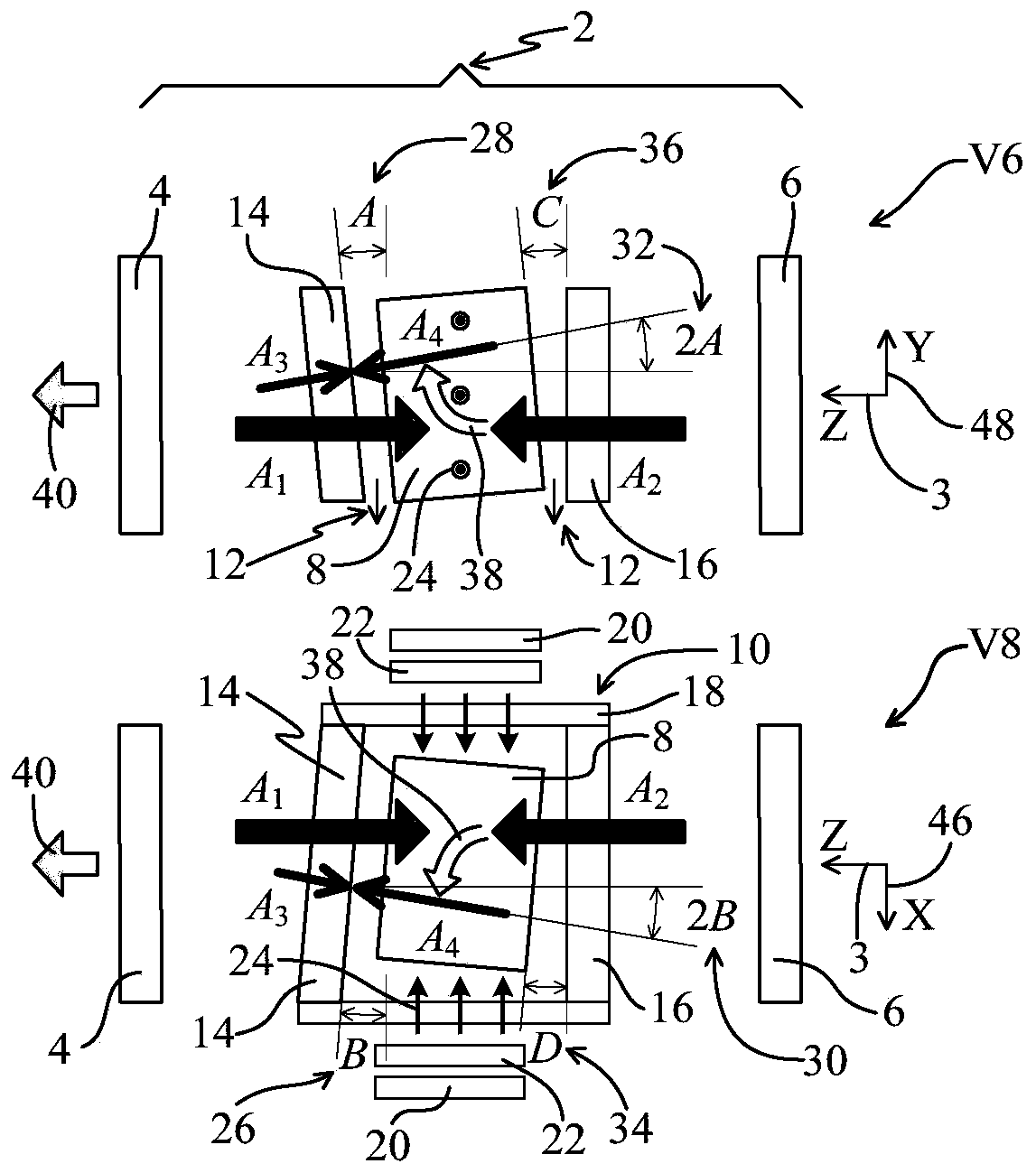

[0034] like figure 2 As shown, it is a schematic structural diagram of the opposite-side pumping mode of an orthogonal volume holographic grating solid-state laser according to an embodiment of the present invention, including the V6 plane view of the Y-Z plane and the V8 plane view of the X-Z plane. The difference between Embodiment 2 and Embodiment 1 lies in that two sets of pumping sources and their coupling devices are used for contralateral pumping and the activation element 8 is placed obliquely.

[0035] As shown in the view of V8, the pumping source 20 is arranged symmetrically on both sides of the front and back of the activation element 8, the pumping source is a semiconductor laser pumping source, and the pumping light 24 emitted by the pumping source 20 passes through the beam shaping system, that is, the coupling device 22 , through the pumping window glass sheet 18 of the liquid cooling chamber 10 , and irradiate on both sides of the activation element 8 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Gain coefficient | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com