Preparation method and application of ternary layered transition metal chalcogenide

A transition metal chalcogenide, ternary layered technology, applied in molybdenum compounds, nickel compounds, cobalt compounds, etc., can solve the problems of high cost, poor stability, multi-step synthesis, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Add 20ml of ammonium sulfide solution with a mass fraction of 16% to 1.5g of ammonium paramolybdate tetrahydrate, stir with a magnetic stirrer for 2.5h, and red gravel-like crystals appear;

[0034] 2) Filter the gravel crystals and wash them repeatedly with absolute ethanol until the filtrate becomes colorless to obtain the precursor;

[0035] 3) Take 4 mmol of the precursor and CoCl respectively 2 ·6H 2 O was dissolved in 80ml of absolute ethanol (10mL) and deionized water (70mL), stirred at room temperature for 3h to obtain a precipitate, left to stand for 2h, filtered, alternately washed with deionized water and ethanol, and centrifuged to dry to obtain Ternary Layered Transition Metal Chalcogenides CoMoS 4 .

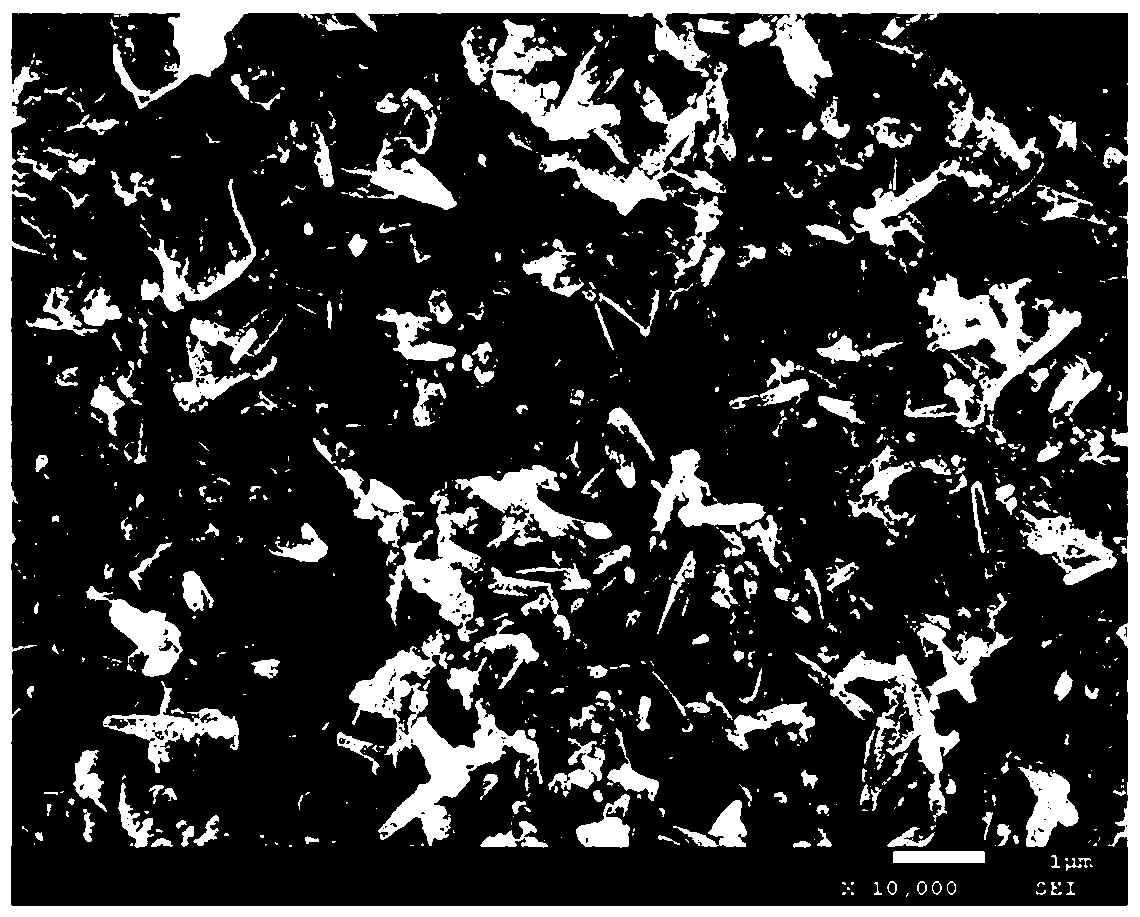

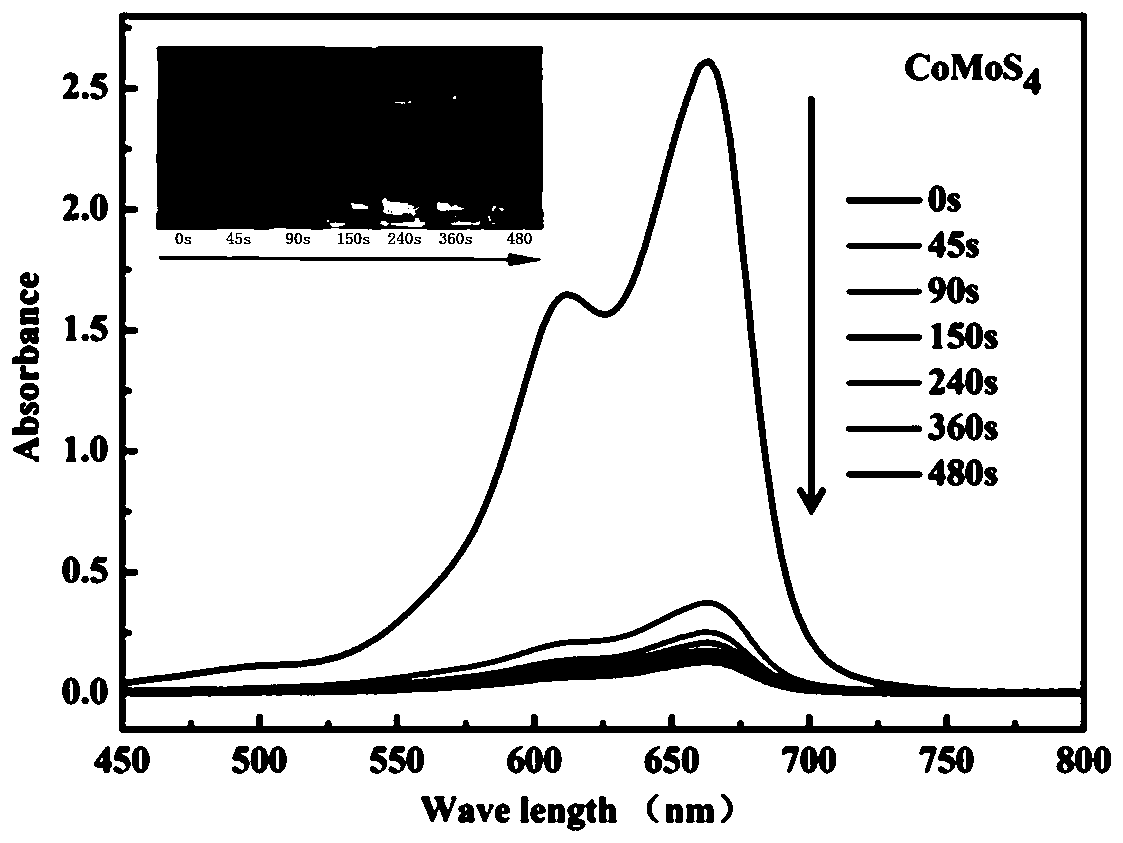

[0036] CoMoS prepared above 4 SEM images of the (see figure 1 ) showed obvious needle-like and granular structures. The adsorption performance shows that the CoMoS prepared by the present invention 4 It has high-efficiency adsorption performance for...

Embodiment 2

[0038] 1) Add 20ml of ammonium sulfide solution with a mass fraction of 16% to 1.5g of ammonium paramolybdate tetrahydrate, stir with a magnetic stirrer for 2.5h, and red gravel-like crystals appear;

[0039] 2) Filter the gravel crystals and wash them repeatedly with absolute ethanol until the filtrate becomes colorless to obtain the precursor;

[0040] 3) Take 4 mmol of the precursor and NiCl respectively 2 ·6H 2O was dissolved in 80ml of absolute ethanol (10mL) and deionized water (70mL), stirred at room temperature for 3h to obtain a precipitate, left to stand for 2h, filtered, alternately washed with deionized water and ethanol, and centrifuged to dry to obtain Ternary Layered Transition Metal Chalcogenides NiMoS 4 .

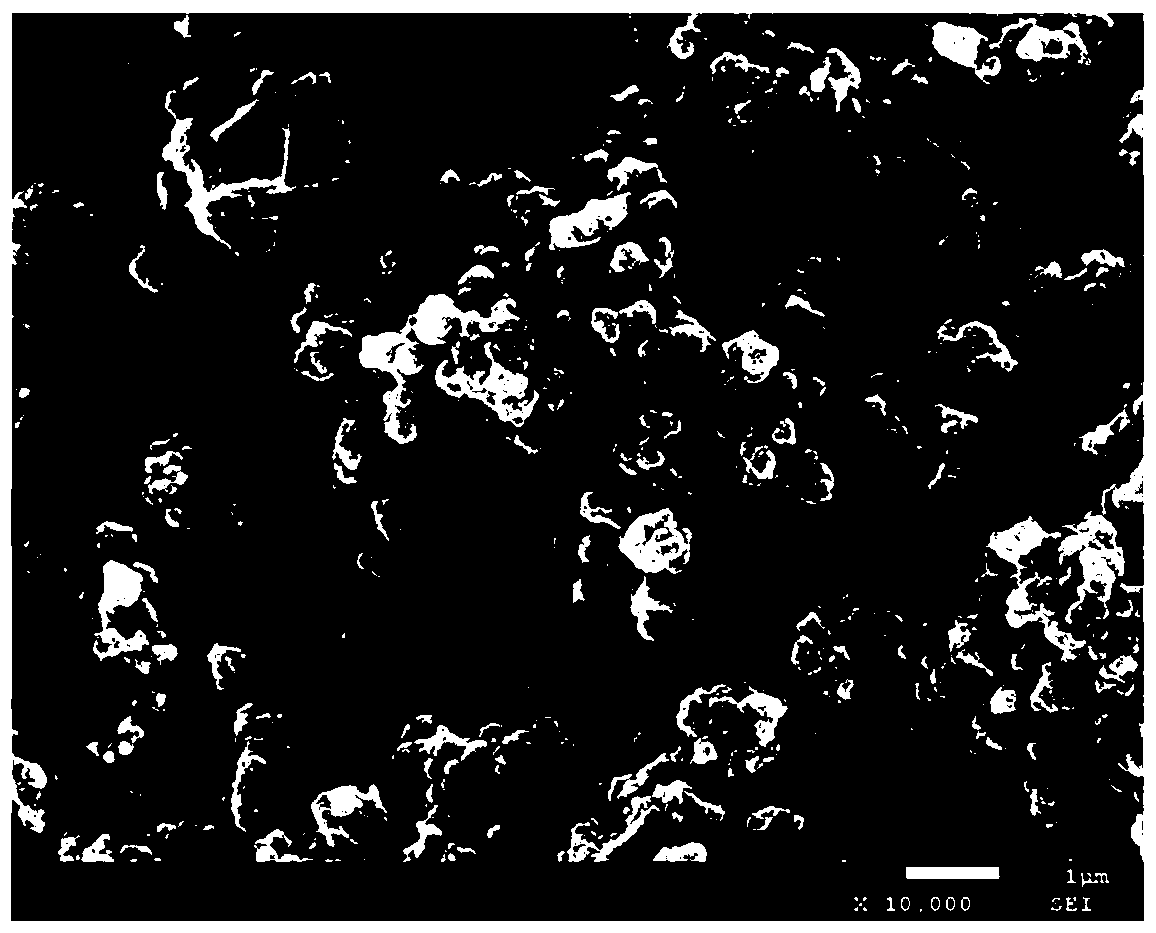

[0041] NiMoS prepared above 4 SEM images of the (see figure 2 ) presents an obvious granular structure. The adsorption performance showed that the adsorption rate of MB in 480S reached 75%.

Embodiment 3

[0043] 1) Add 20ml of ammonium sulfide solution with a mass fraction of 16% to 1.5g of ammonium paramolybdate tetrahydrate, stir with a magnetic stirrer for 2.5h, and red gravel-like crystals appear;

[0044] 2) Filter the gravel crystals and wash them repeatedly with absolute ethanol until the filtrate becomes colorless to obtain the precursor;

[0045] 3) Take 4 mmol of the precursor and CuCl respectively 2 2H 2 O was dissolved in 80ml of absolute ethanol (10mL) and deionized water (70mL), stirred at room temperature for 3h to obtain a precipitate, left to stand for 2h, filtered, alternately washed with deionized water and ethanol, and centrifuged to dry to obtain Ternary Layered Transition Metal Chalcogenides Cu 2 MoS 4 .

[0046] Cu prepared above 2 MoS 4 The SEM images showed obvious block and granular structures. The adsorption properties indicated that the obtained Cu 2 MoS 4 The adsorption rate of RhB reached 76% within 240S, which basically made the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com