High-concentration organic wastewater treatment system and method

A technology for organic wastewater treatment and organic wastewater, applied in water/sewage treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of increasing the input cost of cleaning activated carbon, cumbersome separation of carbon and water, secondary pollution, etc. problems, to achieve the effects of saving pharmaceutical costs, increasing processing pressure, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

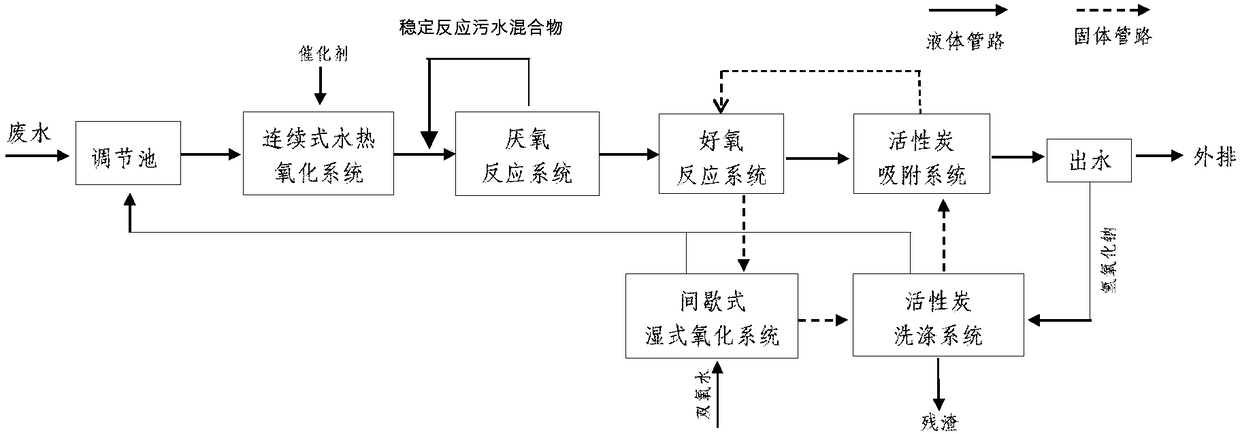

[0040] Such as figure 1 The high-concentration organic wastewater treatment system shown includes a regulating tank, a continuous hydrothermal oxidation system, an anaerobic reaction system, an aerobic reaction system, and an activated carbon adsorption system connected in sequence through liquid pipelines; among them, the activated carbon adsorption system passes solid The pipeline connects the aerobic reaction system, the intermittent wet oxidation system and the activated carbon washing system in sequence to form an activated carbon circulation treatment loop; the effluent part of the activated carbon adsorption system is directly discharged, and part of it is introduced into the activated carbon washing system as washing water; the activated carbon washing system and the intermittent wet type The liquid generated by the oxidation system is collected and directly introduced into the regulating tank through the liquid pipeline. The pipeline between the adjustment tank and th...

Embodiment 2

[0044] Adopt the system described in embodiment 1 to process the method for high-concentration organic waste water:

[0045] The waste water to be treated is: the production waste water of a chemical plant, the pH value is 6.63, and the COD is 20800mg / L.

[0046] Treatment steps: import the waste water to be treated into the adjustment tank, add 30% sodium hydroxide lye according to the actual situation, adjust the pH of the waste water to 9, stir evenly, and put the water on the pipeline between the adjustment tank and the continuous hydrothermal oxidation system Add 2% copper nitrate solution to the dosing mixer according to the demand to keep the catalyst mass concentration at 0.1%, and then introduce a continuous hydrothermal oxidation system; the continuous hydrothermal oxidation system controls the reaction temperature to 280 ° C, and oxygen is used as the oxidant The oxygen purity is 94%, the oxidation coefficient is 0.9, the reaction pressure is 7MPa, and the reaction ...

Embodiment 3

[0058] Adopt the system described in embodiment 1 to process the method for high-concentration organic waste water:

[0059] The waste water to be treated is: the production waste water of a chemical factory, the pH value is 9, and the COD is 41100mg / L.

[0060] Treatment steps: import the wastewater to be treated into the regulating tank, stir evenly, add 2% copper nitrate solution to the catalyst mass concentration in the dosing mixer on the pipeline between the regulating tank and the continuous hydrothermal oxidation system according to the demand Keep it at 0.2%, and introduce a continuous hydrothermal oxidation system; the continuous hydrothermal oxidation system controls the reaction temperature at 300°C, the oxygen purity is 94%, the oxidation coefficient is 0.95, the reaction pressure is 8MPa, and the reaction time is 2h. The COD conversion rate of wastewater treated by the oxidation system is 83.7%, the biodegradability of the effluent is 0.5, and the pH is 7.9; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com