Treatment method of sodium hypophosphite production residues

A sodium hypophosphite and treatment method technology, which is applied in the direction of hypophosphorous acid, phosphorous acid, phosphorus oxyacid, etc., can solve the problems of environmental pollution, high treatment cost, and low product purity, and achieve high purity, simple process, and product yield. The effect of rate stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

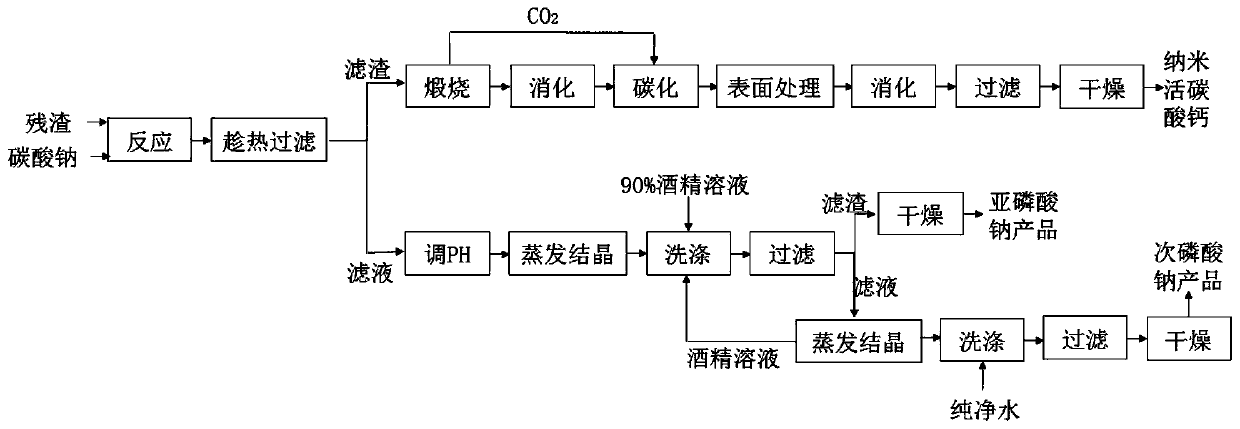

[0031] Combine figure 1 As shown, the method for processing sodium hypophosphite production residues of this embodiment specifically includes the following steps:

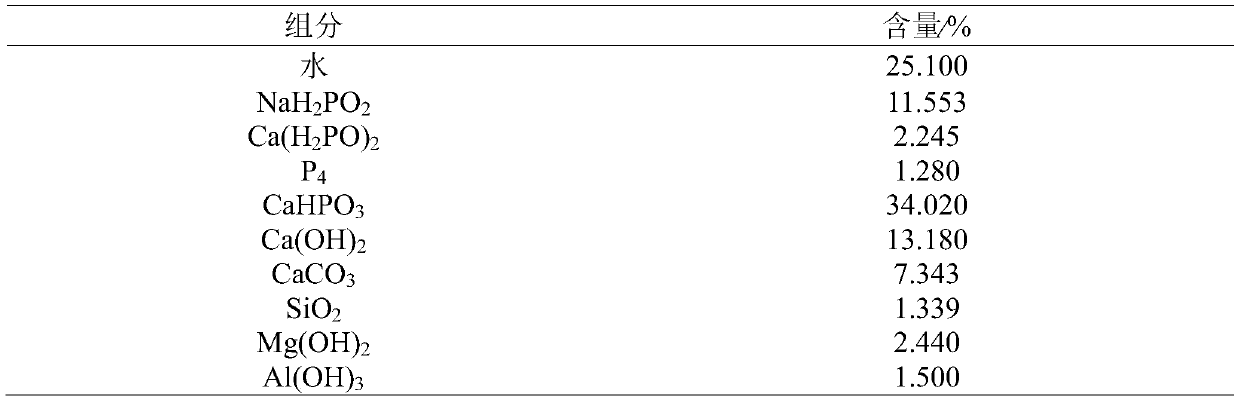

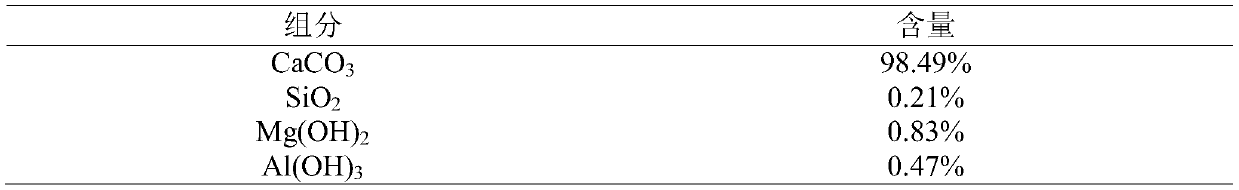

[0032] 1) 100g of sodium hypophosphite production residue, 55g of sodium carbonate, and 800ml of water were sequentially added to a reactor equipped with circulating condensed water and mixed, heated to 100°C, stirred and reacted for 8 hours, and then filtered while hot to obtain filter residue A and The filtrate B, wherein the filter residue A contains high-purity calcium carbonate, and the filtrate B contains sodium phosphite, sodium hypophosphite, and sodium carbonate solution, and in this embodiment, the sodium hypophosphite production residue is mainly contained in the sodium hypophosphite production process. The chemical composition of calcium phosphate, calcium hydroxide, calcium carbonate and industrial residues attached to sodium hypophosphite products is shown in Table 1;

[0033] 2) Adjust the pH of the filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com