Method for extracting citronellal from Litsea cubeba oil front distillate

A technology of litsea cubeba and citronellal, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of waste, etc., and achieve the effects of convenient operation, simple preparation process and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

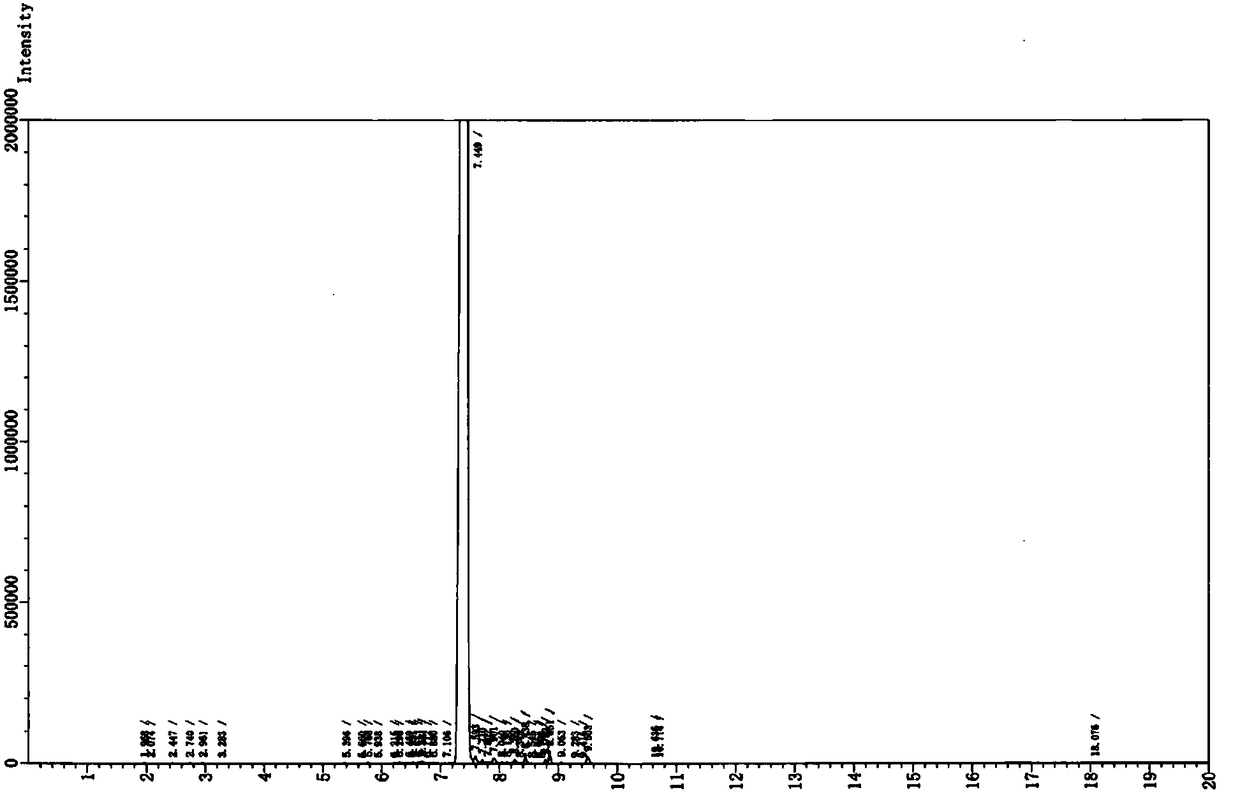

Image

Examples

Embodiment 1

[0042] A method for extracting citronellal from Litsea cubeba head oil of the present invention, wherein, used Litsea cubeba head oil is obtained through crude extraction and distillation from the fresh fruit of Litsea cubeba, and the specific extraction method is as follows:

[0043] (1) Rough extraction of litsea cubeba:

[0044] The picked Litsea cubeba fresh fruit is cleaned, and 150 kg of fresh fruit is weighed and placed in a retort tank in water, and water (225 kg) that is 1.5 times the weight of the Litsea cubeba fresh fruit is added. Use 4kg of pressure water vapor as the heating carrier, and use a 1000L multi-functional extraction device for extraction, adjust the temperature and steam pressure of the water distillation, and control the return flow at 150L / h;

[0045] After the distillation, the material in the distillation flask is filtered through a filter screen, and the remaining water in the flask is used as the water for the next feeding. The dried fruit in th...

Embodiment 2

[0059] A method for extracting citronellal from Litsea cubeba head oil of the present invention, wherein, used Litsea cubeba head oil is obtained through crude extraction and distillation from the fresh fruit of Litsea cubeba, and the specific extraction method is as follows:

[0060] (1) Rough extraction of litsea cubeba:

[0061] The picked Litsea cubeba fresh fruit is cleaned, and 150 kg of fresh fruit is taken by weighing and placed in a retort tank in water, and water (225 kg) that is 1.5 times the weight of the Litsea cubeba fresh fruit is added. Use 4kg of pressure water vapor as the heating carrier, and use a 1000L multi-functional extraction device for extraction, adjust the temperature and steam pressure of the water distillation, and control the return flow at 150L / h;

[0062] After the distillation is over, the material in the distillation is filtered through a filter screen, and the remaining water in the flask is used as the water for the next feeding. The dried...

Embodiment 3

[0073] A method for extracting citronellal from Litsea cubeba head oil of the present invention, wherein, used Litsea cubeba head oil is obtained through crude extraction and distillation from the fresh fruit of Litsea cubeba, and the specific extraction method is as follows:

[0074] (1) Rough extraction of litsea cubeba:

[0075]The picked Litsea cubeba fresh fruit is cleaned, and 150 kg of fresh fruit is taken by weighing and placed in a retort tank in water, and water (225 kg) that is 1.5 times the weight of the Litsea cubeba fresh fruit is added. Use 4kg of pressure water vapor as the heating carrier, and use a 1000L multi-functional extraction device for extraction, adjust the temperature and steam pressure of the water distillation, and control the return flow at 150L / h;

[0076] After the distillation is over, the material in the distillation is filtered through a filter screen, and the remaining water in the flask is used as the water for the next feeding. The dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com