A kind of anti-fog/anti-frost coating based on cationic polyelectrolyte copolymer and preparation method thereof

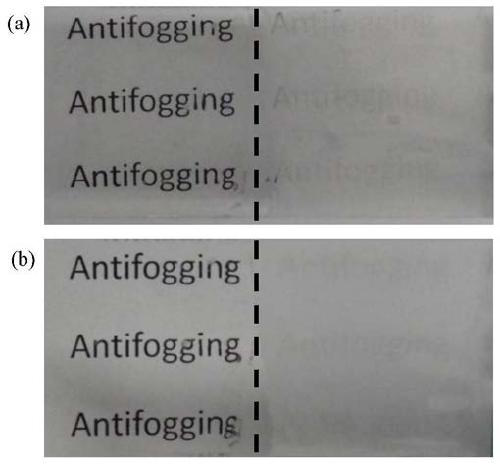

A cationic poly-electrolyte technology, applied in the direction of coating, etc., can solve the problems of reducing the actual application value of the coating, and it is difficult to ensure the long-term anti-fog and anti-frost properties of the coating, so as to achieve good anti-fog effect and long-term effect Sexuality, the effect that the strength is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

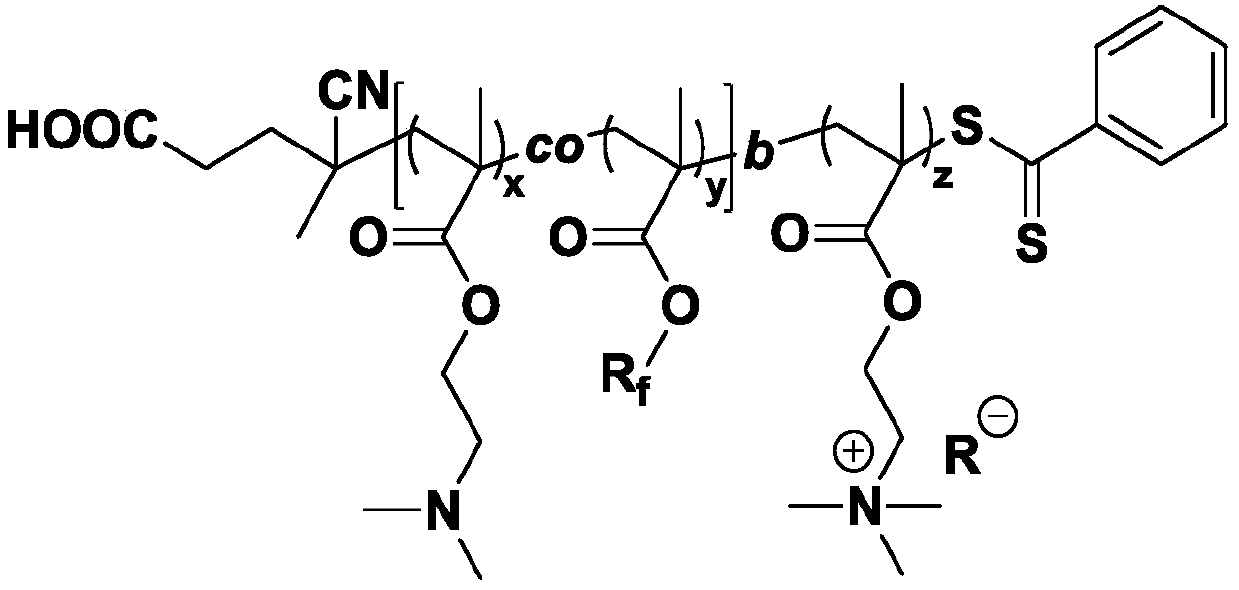

[0036](1) Poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate)-b-cationic polyelectrolyte (R=Cl - ) Synthesis:

[0037] Weigh the medicine according to the molar ratio of dimethylaminoethyl methacrylate, trifluoroethyl methacrylate, 4-cyanopentanoic acid dithiobenzoic acid and azobisisobutyronitrile as 150:20:1:0.2, Configure it as a 50% toluene solution, remove the oxygen in the system, and place it in a 70°C oil bath for 10 hours. After the reaction, quench it with liquid nitrogen, precipitate it in ice-n-hexane for 5 times, and dry it in a vacuum oven. After 24h, poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate) was obtained.

[0038] According to the molar ratio of azodicyanovaleric acid, poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate), methacryloyloxyethyltrimethylammonium chloride is 0.25:1 :30 Weigh the medicine, make it a 20% isopropanol / water (1:1, v / v) solution with a mass fraction, after the oxygen in the sys...

Embodiment 2

[0050] (1) Poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate)-b-cationic polyelectrolyte (R=SO 4 2- )Synthesis:

[0051] Weigh the medicine according to the molar ratio of dimethylaminoethyl methacrylate, trifluoroethyl methacrylate, 4-cyanopentanoic acid dithiobenzoic acid and azobisisobutyronitrile as 50:10:1:0.2, Configured as a 20% toluene solution, after removing the oxygen in the system, put it in a 65°C oil bath for 24 hours, after the reaction, quench it with liquid nitrogen, precipitate in ice n-hexane for 3 times, and dry it in a vacuum oven After 48 hours, poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate) was obtained.

[0052] According to the molar ratio of azodicyanovaleric acid, poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate), methacryloyloxyethyltrimethylammonium chloride is 0.25:1 :10 Weigh the medicine, make it into 10% isopropanol / water (1:1, v / v) solution with a mass fraction, after the oxygen in ...

Embodiment 3

[0064] (1) poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate)-b-cationic polyelectrolyte (R=I - ) Synthesis:

[0065] Weigh the medicine according to the molar ratio of dimethylaminoethyl methacrylate, trifluoroethyl methacrylate, 4-cyanopentanoic acid dithiobenzoic acid and azobisisobutyronitrile as 300:60:1:0.2, Configure it as a 50% toluene solution, remove the oxygen in the system, and place it in an oil bath at 80°C to react for 8 hours. After the reaction, quench it with liquid nitrogen, precipitate it in ice n-hexane for 4 times, and dry it in a vacuum oven. 36h, poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate) was obtained.

[0066] According to the molar ratio of azodicyanovaleric acid, poly(dimethylaminoethyl methacrylate-co-trifluoroethyl methacrylate), methacryloyloxyethyltrimethylammonium chloride is 0.25:1 :200 Weigh the medicine, make it into 50% isopropanol / water (1:1, v / v) solution with a mass fraction, after exhausting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com