Method for using gas chromatography-mass spectrometry to detect content of phthalic anhydride in toy

A technology of phthalic anhydride and GC-MS, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of poor anti-interference ability and false positive, and achieve the effect of good solubility and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

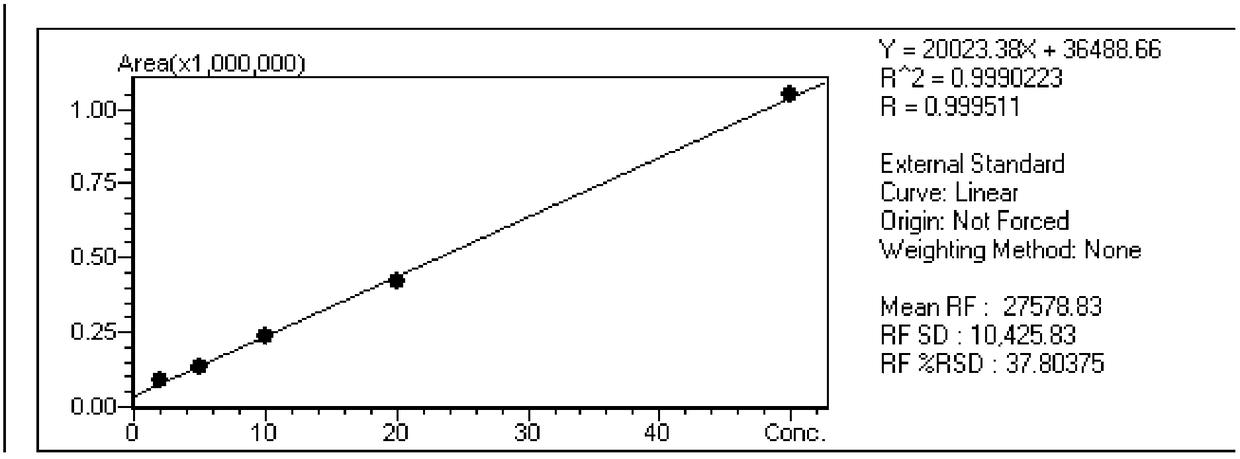

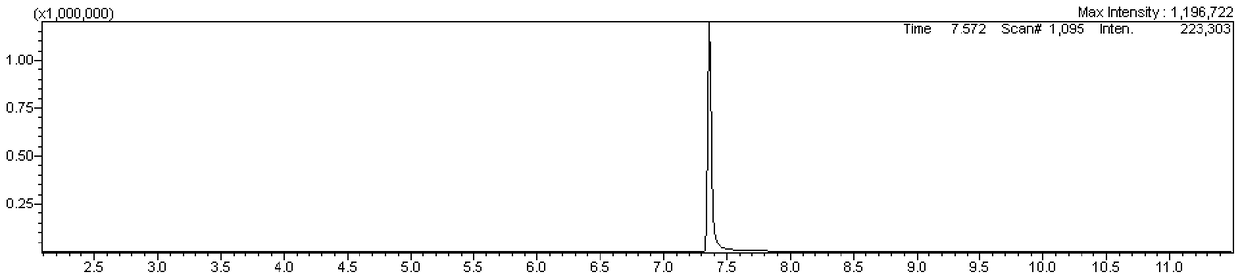

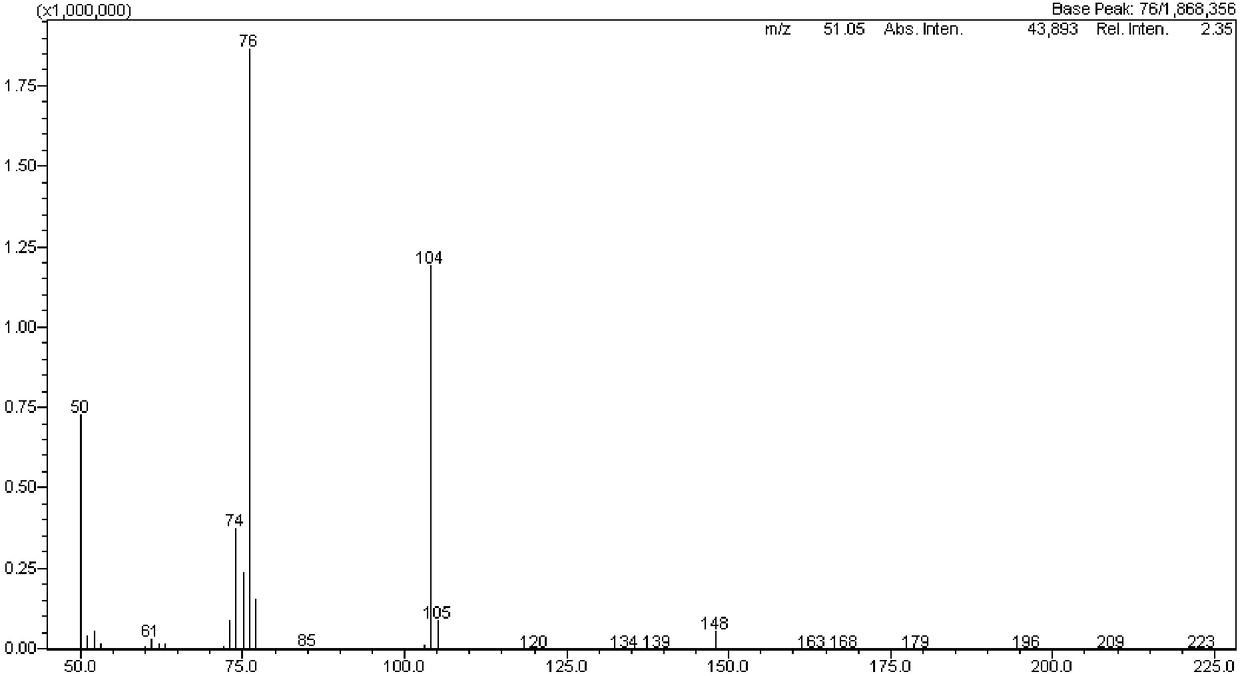

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for detecting the content of phthalic anhydride in toys by gas chromatography-mass spectrometry, comprising the following steps:

[0035] The first step is to take a sample from the toy: use stainless steel scissors to cut the toy sample into small rectangular pieces with a diagonal length not greater than 5mm.

[0036] In the second step, weigh 1.0 g of the shredded sample and place it in a 40 mL container (reaction tube in this example), then add 10 mL of toluene to the container, shake it so that the sample is completely submerged in toluene, and screw on the bottle cap , put the container in an ultrasonic cleaner for ultrasonic extraction for 60 minutes, the ultrasonic frequency is 50 kHz, and the ultrasonic temperature is 40° C. to obtain the extract;

[0037] The third step is to filter the extract obtained in the second step to obtain the test solution, specifically, filter 2 mL of the extract with a 0.45 μm polytetrafluoroethyle...

Embodiment 2

[0058] The difference from Example 1 lies in the first step to the third step:

[0059] The first step is to take a sample from the toy: use stainless steel scissors to cut the sample into small round pieces with a diameter of no more than 5mm.

[0060] In the second step, take 1.0 g of the shredded sample and place it in a 40 mL container (reaction tube in this embodiment), then add 8 mL of toluene to the container, shake it, so that the sample is completely submerged in toluene, and screw on the bottle cap , put the container in an ultrasonic cleaner for ultrasonic extraction for 120min, the ultrasonic frequency is 80kHz, and the ultrasonic temperature is 42°C to obtain the extract;

[0061] The third step is to filter the extract obtained in the second step to obtain the test solution, specifically, filter 2 mL of the extract with a 0.35 μm polytetrafluoroethylene filter membrane into the sample bottle;

[0062] The rest are the same as in Embodiment 1, and will not be rep...

Embodiment 3

[0066] The difference from Example 1 lies in the first step to the third step:

[0067] The first step is to take a sample from the toy: use stainless steel scissors to cut the sample into small oval pieces with a long axis of no more than 5mm.

[0068] In the second step, weigh 1.0 g of the shredded sample and place it in a 40 mL container (reaction tube in this embodiment), then add 12 mL of toluene to the container, shake it so that the sample is completely submerged in toluene, and screw on the bottle cap , put the container in an ultrasonic cleaner for ultrasonic extraction for 150 minutes, the ultrasonic frequency is 40kHz, and the ultrasonic temperature is 35°C to obtain the extract;

[0069] The third step is to filter the extract obtained in the second step to obtain the test solution, specifically, filter 2 mL of the extract with a 0.22 μm polytetrafluoroethylene filter membrane into the sample bottle;

[0070] The rest are the same as in Embodiment 1, and will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com