Automatic detection and early warning system for numerical control machine tool and operation method of automatic detection and early warning system

A technology of CNC machine tools and early warning systems, applied in general control systems, control/adjustment systems, program control, etc., can solve problems such as no early warning, no early warning, tool prediction, etc., so as to facilitate the detection of danger, save time, and improve The effect of precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

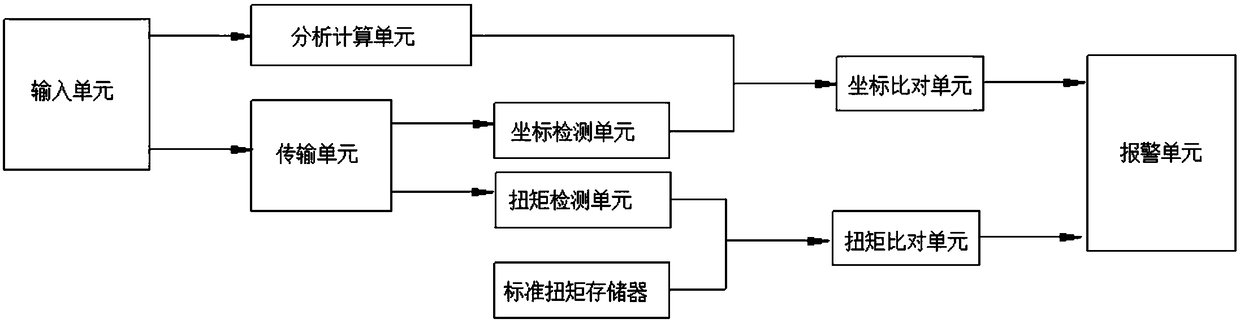

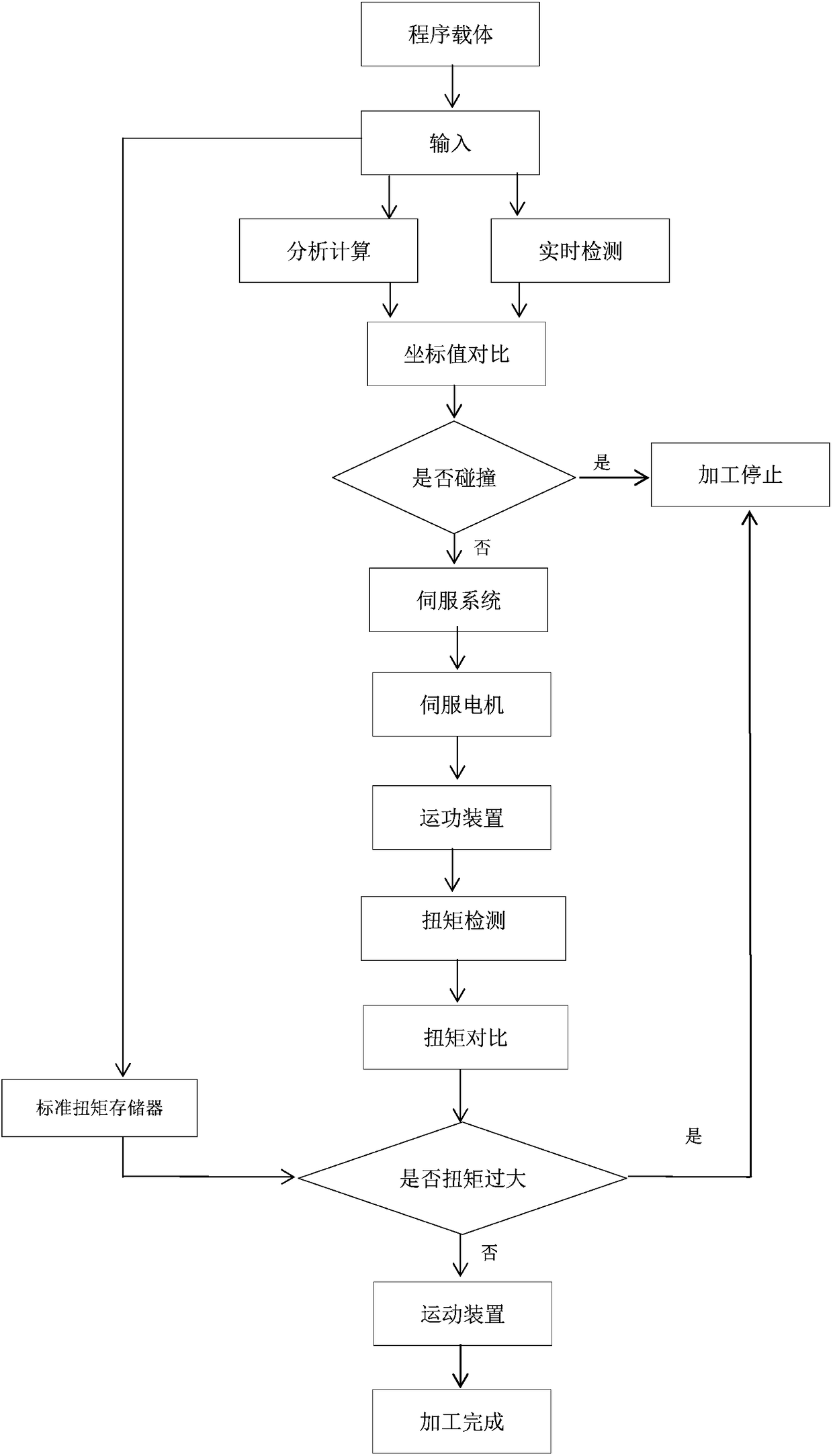

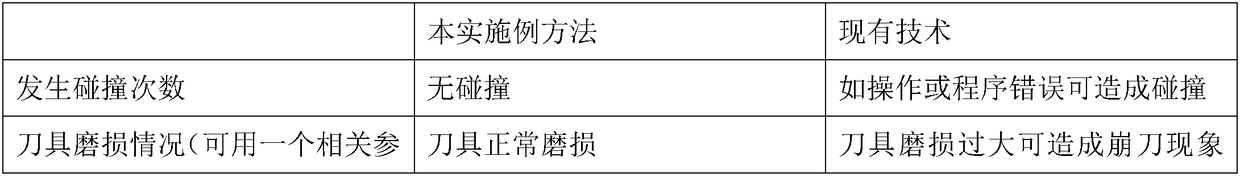

[0061] An automatic detection and early warning system for CNC machine tools, such as figure 1 As shown, it includes an input unit, a transmission unit, an analysis and calculation unit, a coordinate detection unit, a coordinate comparison unit, and an alarm unit;

[0062] The input unit is respectively connected to the transmission unit and the analysis calculation unit, the transmission unit is connected to the coordinate detection unit, the analysis calculation unit and the coordinate detection unit are connected to the coordinate comparison unit, and the coordinate comparison unit is connected to the alarm unit;

[0063] The input unit is used to read the processing program into the machine tool and convert it into a readable analog signal;

[0064] The analysis and calculation unit is used to read the processing program and calculate the theoretical coordinate value;

[0065] The transmission unit is used to drive the mechanical parts of the machine tool to move the read...

Embodiment 2

[0070] According to a kind of CNC machine tool automatic detection and early warning system described in embodiment 1, its difference is that,

[0071] The input unit is USB or operation panel;

[0072] The analysis and calculation unit includes a PLC host computer and a single-chip microcomputer; the processing program is input to the single-chip integrated board, and all of them are converted into information codes acceptable to the numerical control device through the CPU, and then transmitted to the PLC host computer. The PLC host computer obtains theoretical coordinate values through information exchange processing ;

[0073] The transmission unit includes a servo motor, a lead screw, and a servo driver; the servo driver sends a readable analog signal (command) to the servo motor, and the servo motor is connected to the lead screw through a coupling, and receives the command from the servo driver to realize rotation and drive the wire Lever operation; the servo control...

Embodiment 3

[0080] A kind of CNC machine tool automatic detection and early warning system according to embodiment 1 or 2, its difference is that,

[0081] The CNC machine tool automatic detection and early warning system also includes a torque detection unit, a torque comparison unit, and a standard torque memory;

[0082] The transmission unit is connected to the torque detection unit, the torque detection unit and the standard torque memory are connected to the torque comparison unit, and the torque comparison unit is connected to the alarm unit;

[0083] The torque detection unit is used to detect the torque and cutting force of each servo motor in real time;

[0084] The torque comparison unit is used to compare the real-time detected torque of the servo motor with the torque value of the servo motor stored in the standard torque memory. If the difference between the two is within the range of the threshold B, the CNC machine tool is working normally; otherwise, an alarm will be issu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com