Preparation method of source field plate of GaN-based HEMT device and HEMT device

A source field plate and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem that the performance of GaN-based HEMT devices cannot be well improved, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

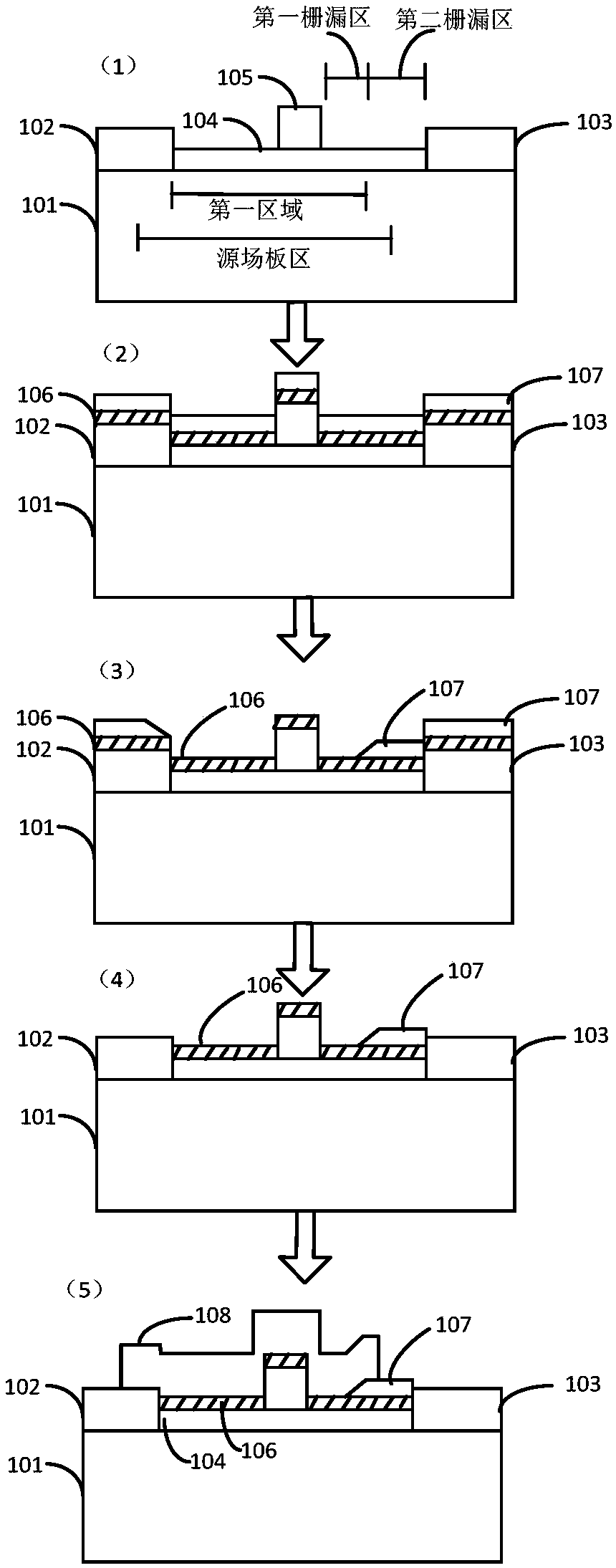

[0040] Please refer to figure 2 , a method for preparing a source field plate of a GaN-based HEMT device, comprising:

[0041] Step S201, sequentially growing a SiN layer of the first thickness and a SiO layer of the second thickness on the upper surface of the device 2 layer.

[0042] In the embodiment of the present invention, please refer to figure 1 (2), first clean the GaN-based HEMT device, and then sequentially deposit a SiN layer 106 with a first thickness and a SiO with a second thickness on the upper surface of the device by an ion-enhanced chemical vapor deposition (Plasma Enhanced Chemical Vapor Deposition, PECVD) process 2 layer 107, SiN layer 106 and SiO 2 Layer 107 serves as two dielectric layers with high etch selectivity. SiN layer 106 and SiO 2 The thickness of layer 107 can be set according to actual needs, preferably, the thickness of SiN layer 106 is 50 nanometers to 200 nanometers, SiO 2 Layer 107 has a thickness of 50 nm to 800 nm.

[0043] Step ...

Embodiment 2

[0058] Please refer to Figure 5 , a HEMT device, comprising a HEMT device body, a source gate region, a gate electrode region and a gate drain region of the HEMT device body covering a SiN layer 106 of a first thickness, the SiN layer 106 corresponding to the first gate drain region The upper surface is covered with a second thickness of SiO 2 layer 107, the SiO 2 The surface of layer 107 facing the gate electrode region is inclined; wherein, the first gate drain region is connected to the drain electrode region; the source field plate region on the upper surface of the HEMT device covers the metal layer 108 with a third thickness , the source field plate region includes a preset portion of the source electrode region, a source gate region, a gate electrode region and a preset portion of the gate drain region, the preset portion of the source electrode region, the source gate region, the gate The predetermined parts of the electrode region and the gate-drain region are sequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com