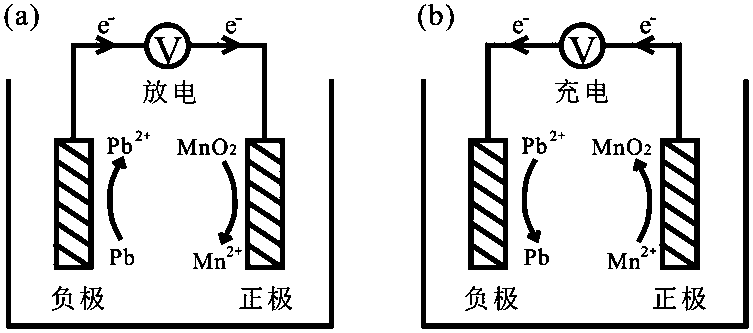

Lead-manganese secondary battery

A secondary battery and electronic technology, applied in the direction of semi-lead batteries, etc., can solve the problems of inability to meet fast energy storage, low cycle life, etc., and achieve the effects of high power density, stable cycle life, and high cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

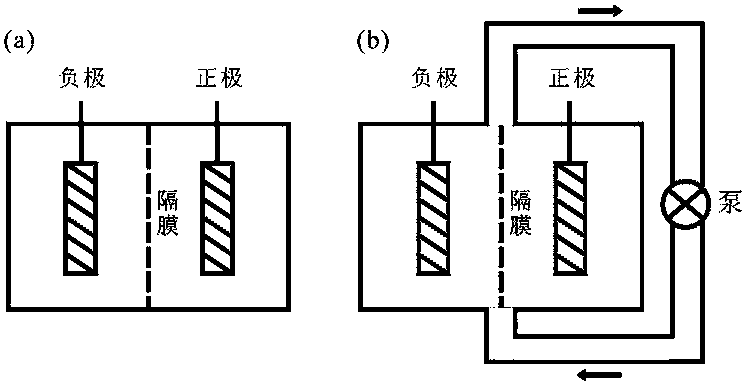

[0018] Example 1: Novel lead-manganese battery, positive electrode: carbon felt material deposited with manganese dioxide, negative electrode: lead grid plate filled with spongy lead, electrolyte: 2M sulfuric acid.

[0019] In this example, the positive current collector adopts carbon felt deposited with manganese dioxide, and the electrolyte is 2 mol / L sulfuric acid solution. The separator is a non-woven fabric, which only serves to prevent short-circuiting of the positive and negative electrodes. 10mA / cm 2 Discharge to 0.6V at current density, charge to 9 mAh at a constant voltage of 1.6 V (1 mAh / cm 2 ), the Coulombic efficiency reached 100% after 90 cycles. at 30 mA / cm 2 In the case of discharge, the Coulombic efficiency reaches 99%, and it can stably cycle 15,000 times.

Embodiment 2

[0020] Example 2: Novel lead-manganese battery, positive electrode: carbon paper deposited with manganese dioxide, negative electrode: lead grid filled with spongy lead, electrolyte: 2M sulfuric acid.

[0021] In this example, the positive current collector is carbon paper deposited with manganese dioxide, and the electrolyte is 2 mol / L manganese sulfate solution. The separator is a non-woven fabric, which only serves to prevent short-circuiting of the positive and negative electrodes. 10mA / cm 2 Discharge to 0.6V at current density, charge to 9 mAh at a constant voltage of 1.6 V (1 mAh / cm 2 ), the Coulombic efficiency reached 100% after 60 cycles. at 30 mA / cm 2 In the case of discharge, the Coulombic efficiency reaches 97%, and it can be stably cycled for 10,000 times.

Embodiment 3

[0022] Example 3: Novel lead-manganese battery, positive electrode: conductive graphite plate deposited with manganese dioxide, negative electrode: lead grid plate filled with spongy lead, electrolyte: 2M sulfuric acid + 1M MnSO 4 solution.

[0023] In this example, the positive current collector uses a conductive graphite plate deposited with manganese dioxide, and the electrolyte is 2 mol / L sulfuric acid + 1M MnSO 4 solution. The separator is a non-woven fabric, which only serves to prevent short-circuiting of the positive and negative electrodes. 10mA / cm 2 Discharge to 0.6V at current density, charge to 9 mAh at a constant voltage of 1.6 V (1 mAh / cm 2), the Coulombic efficiency reached 100% after 50 cycles. at 30mA / cm 2 In the case of discharge, the Coulombic efficiency reaches 98%, and it can stably cycle 12,000 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com