Cement accelerator

A coagulant and cement technology, which is applied in the field of cement coagulant, can solve the problems of mud rheology decrease, cement slurry thickening, flash coagulation, etc., and achieve the effect of improving dispersion retention ability, promoting coagulation, and preventing flash coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

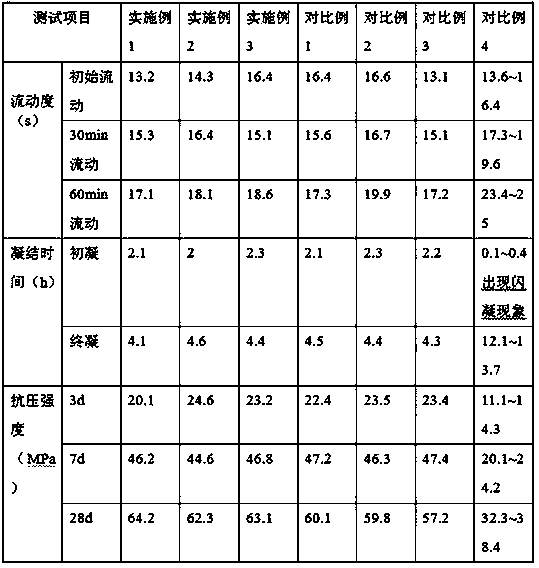

Examples

preparation example Construction

[0019] The preparation method of the additive solution is as follows: take eighteen hydrated aluminum sulfate, add polyacrylamide and water to mix at a mass ratio of 15:3:10, stir and mix at 35~45°C for 2~3 hours, then add eighteen hydrated aluminum sulfate with a mass of 40~ 50% calcium oxide, heat up to 60~65°C, keep at 1500r / min high-speed shear for 1~3h to obtain a mixture, take sodium hydroxide and add water at a mass ratio of 1:10, then add sodium hydroxide with a mass of 5~8 Double the mixture, heat it up to 70-80°C for 3-4 hours, filter with suction, and take the filtrate to obtain the additive solution.

[0020] The preparation method of coagulant matrix thing comprises the steps:

[0021] (1) According to the number of parts by mass, take 5~8 parts of acrylic acid, 2~4 parts of α-hydroxyethyl acrylate, 0.3~0.5 parts of dimethyldiallyl ammonium chloride, 20~30 parts of water, in 45 Stir and mix at ~50°C for 1~2h to obtain the mixed solution A. According to the number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com