Sand-carrying liquid used for sand prevention of unconsolidated sandstone heavy oil reservoir

A technology for heavy oil reservoirs and sand-carrying fluids, which is applied in the fields of production fluids, wellbore/well components, drilling compositions, etc., and can solve the change of high-temperature rheological properties of sand-carrying fluids and the lack of pertinence of heavy oil reservoirs. , Unable to achieve high sand ratio filling and other problems, to achieve the effect of improving reservoir development effect, improving development effect, and solving water-sensitive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of sand-carrying fluid for sand control in unconsolidated sandstone heavy oil reservoirs

[0026] The components are as follows: 0.5% of the main agent of the sand-carrying liquid, 1.5% of the cleaning agent, 4% of the clay stabilizer, 1.0% of the water damage treatment agent, and the balance is water.

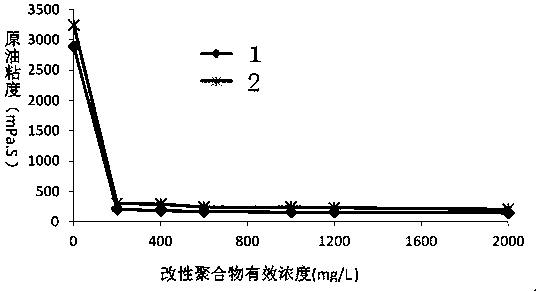

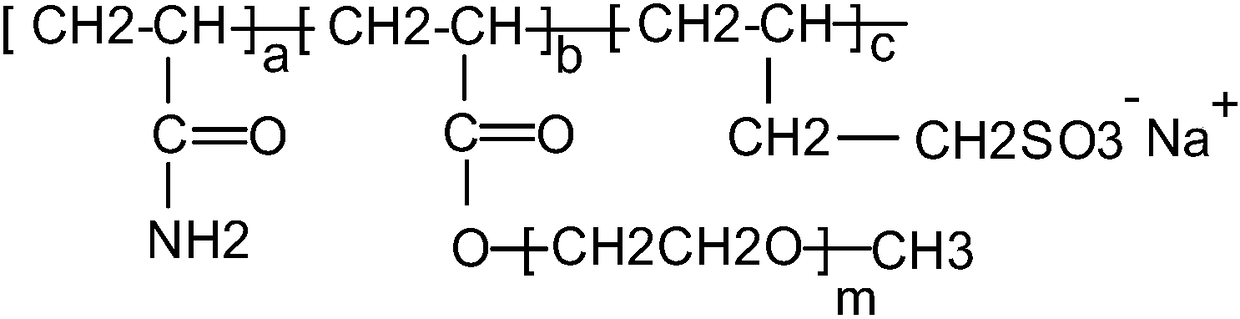

[0027] The main agent of the sand-carrying liquid is acrylamide-polyether acrylate-sodium n-butene sulfonate copolymer (obtained by acrylamide, polyether acrylate, and sodium n-butene sulfonate by conventional methods), wherein, a is an integer between 1000 and 1200, b and c are both integers between 800 and 1000, and m is an integer between 400 and 600.

[0028] The cleaning agent is sodium cetylbenzenesulfonate.

[0029] The clay stabilizer is a compound of an inorganic stabilizer and a quaternized polyether amine, and the inorganic stabilizer is NH 4 Cl; the quaternized polyetheramine is SLFP-G1 purchased from Shengli Oilfield Shengli Chemical...

Embodiment 2

[0032] Example 2 Preparation of sand-carrying fluid for sand control in unconsolidated sandstone heavy oil reservoirs

[0033] The components are as follows: 0.45% of the main agent of the sand-carrying liquid, 2% of the cleaning agent, 3% of the clay stabilizer, 1.5% of the water damage treatment agent, and the balance is water.

[0034] The main agent of the sand-carrying liquid is acrylamide-polyether acrylate-sodium n-butene sulfonate copolymer (obtained by acrylamide, polyether acrylate, and sodium n-butene sulfonate by conventional methods), wherein, a is an integer between 1200 and 1500, b and c are both integers between 1000 and 1200, and m is an integer between 600 and 800.

[0035] The cleaning agent is sodium dodecylbenzenesulfonate.

[0036] The clay stabilizer is a compound of an inorganic stabilizer and a quaternized polyether amine, and the inorganic stabilizer is selected from NH 4 Cl, KCl; the weight ratio of the inorganic stabilizer and polyetheramine is 2:...

Embodiment 3

[0039] Example 3 Preparation of sand-carrying fluid for sand control in unconsolidated sandstone heavy oil reservoirs

[0040] The components are as follows: 0.6% of the main agent of the sand-carrying liquid, 1% of the cleaning agent, 5% of the clay stabilizer, 0.5% of the water damage treatment agent, and the balance is water.

[0041] The main agent of the sand-carrying liquid is acrylamide-polyether acrylate-sodium n-butene sulfonate copolymer (obtained by acrylamide, polyether acrylate, and sodium n-butene sulfonate by conventional methods), wherein, a is an integer between 1000 and 1200, b and c are both integers between 800 and 1000, and m is an integer between 400 and 600.

[0042] The cleaning agent is sodium cetylbenzenesulfonate.

[0043] The clay stabilizer is a composite of an inorganic stabilizer and a quaternized polyetheramine, and the inorganic stabilizer is KCl; the weight ratio of the inorganic stabilizer to the polyetheramine is 3:1.

[0044] The water da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com