Ultra-wide forbidden band ZrxSn1-xO2 alloy semiconductor epitaxial thin film material and preparation method, application and device thereof

A zrxsn1-xo2, epitaxial thin film technology, applied in semiconductor devices, metal material coating process, electrical components and other directions, to achieve the effect of simple and convenient equipment and operation, cheap and easy-to-obtain raw materials, and low-cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

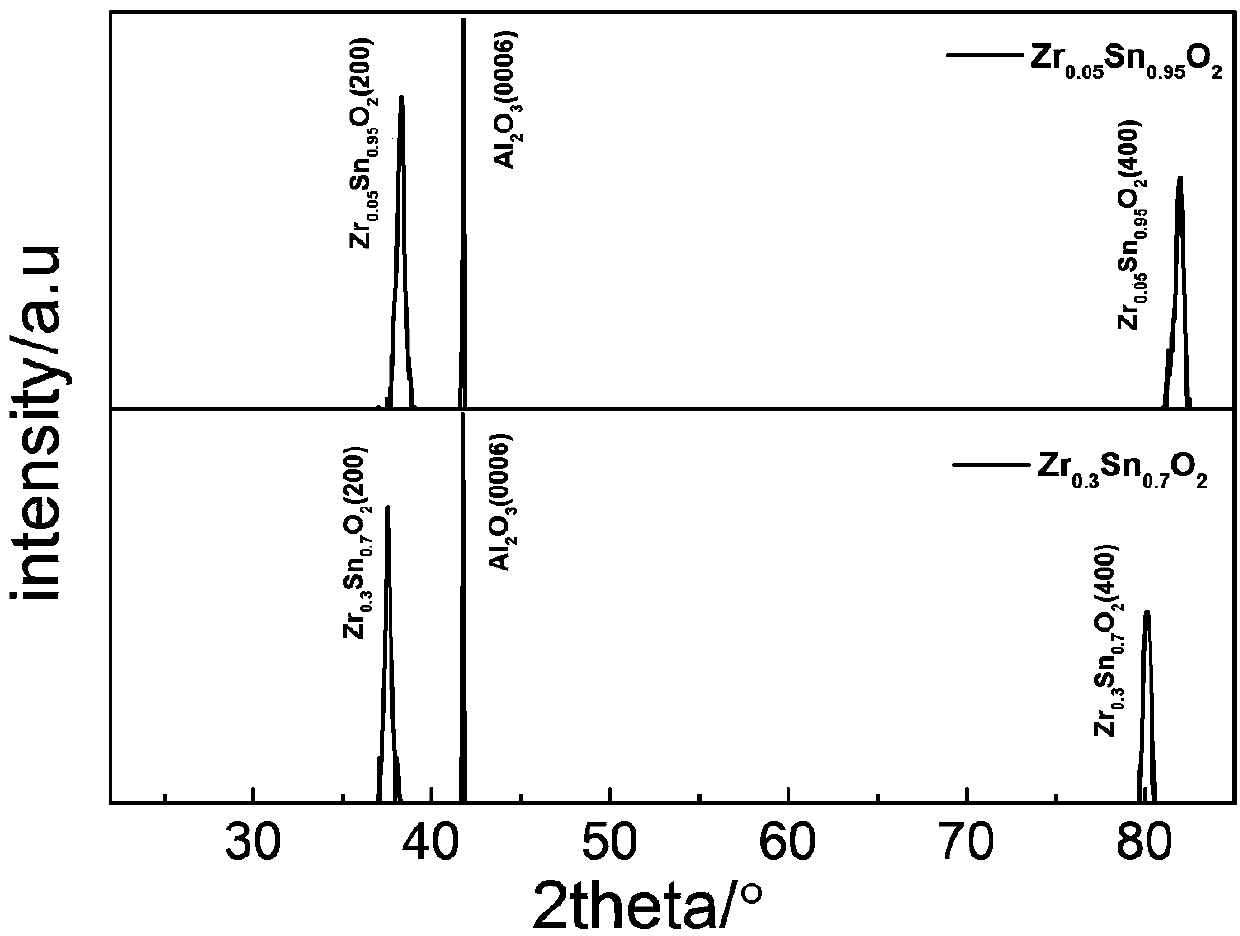

Embodiment 1

[0042] According to Zr 0.05 sn 0.95 o 2 This doping formula weighs the SnO 2 19.1748g, ZrO 2 0.8252g for initial mixing of ingredients, then pour the mixed material into a ball mill tank and add absolute ethanol accounting for about 60% of the total powder mass, and then put it into a ball mill for 8 hours to make it fully and evenly mixed , and then wash the material that has been fully ball-milled and evenly mixed, such as with absolute ethanol, and transfer it to an evaporating dish, and then put it in a drying oven for drying treatment. After drying, the mixed material is transferred to the grinder Add absolute ethanol accounting for about 6% of the total mass of the powder into the bowl as a bonding agent, carry out sufficient grinding treatment to make the powder evenly bonded together to form a billet, and then use an electromagnetic hydraulic press to press the billet under a pressure of 4-6MPa Press into a ceramic green sheet with a mass of about 10g and a thick...

Embodiment 2

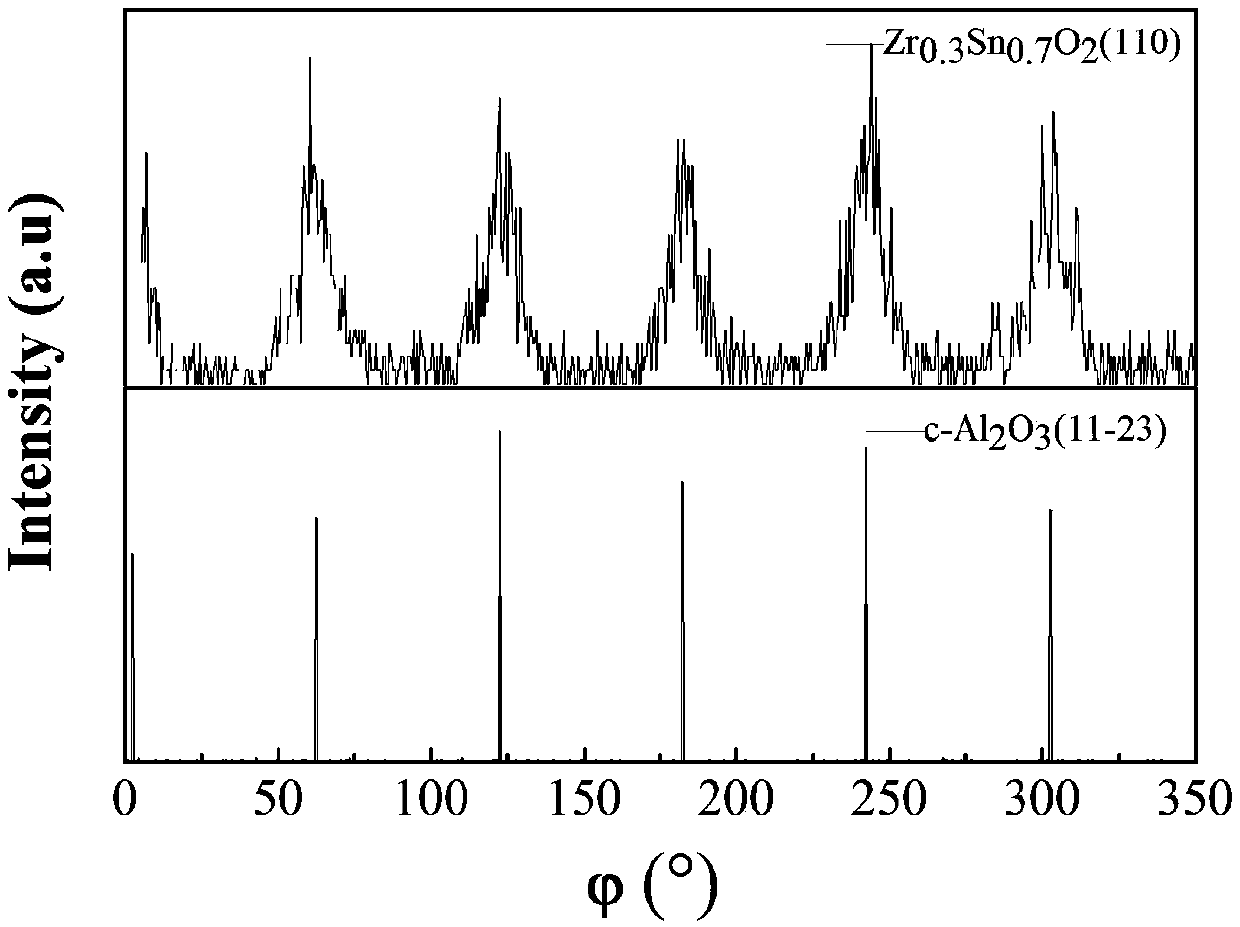

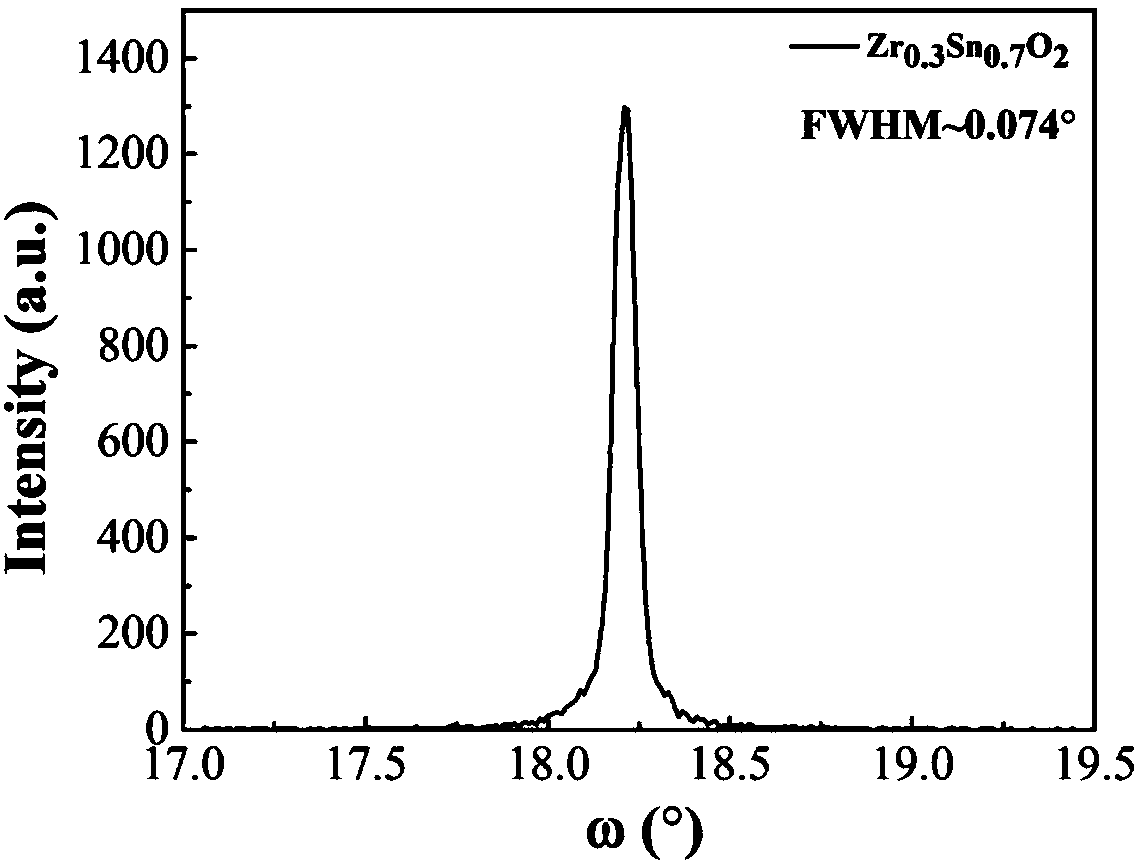

[0044] According to Zr 0.3 sn 0.7 o 2 This doping formula weighs the SnO 2 14.8102g, ZrO 2 5. 1898g for the initial mixing of the ingredients, then pour the mixed material into the ball mill tank and add anhydrous ethanol accounting for about 60% of the total powder mass, and then put it into the ball mill for 8 hours to make it fully and evenly mixed , and then wash the material that has been fully ball-milled and evenly mixed, and transfer it to an evaporating dish, and then put it in a drying oven for drying treatment. After drying, transfer the mixed material to a mortar and add Absolute ethanol, which accounts for about 6% of the total powder mass, is used as an adhesive agent, and the powder is evenly bonded together to form a billet after sufficient grinding treatment, and then the billet is pressed to a mass of about 10g under a pressure of 4-6MPa by an electromagnetic hydraulic press. The ceramic green sheet with a thickness of about 2-3mm is then placed in a tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com