Self-repairing oxidization film-coated Na-K liquid-state alloy electrode and preparation method and application thereof

A liquid alloy and oxide film technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve Na-K liquid alloy shedding, without any solution strategy, and does not aim at stabilizing Na-K liquid alloy electrodes and electrolysis Liquid and other problems, to achieve high Coulombic efficiency, improve energy density and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

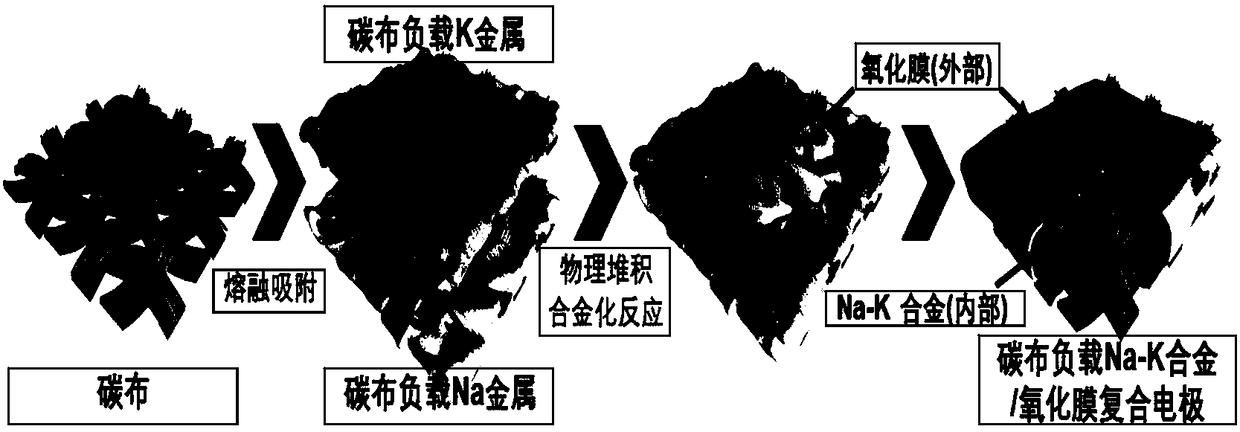

[0046] Heat 0.1g of K metal and 0.028g of Na metal in a glove box to 450°C and melt respectively, and then use tweezers to contact carbon cloth (thickness 2mm) with a length of 1cm with the two molten metals, and take them out after they are completely absorbed. Cool to room temperature 25°C. Stack the carbon cloth loaded with K metal and Na metal respectively, and the alloying reaction of the two metals occurs on the surface of the carbon cloth, and a self-healing oxide film is formed on the surface. After a period of reaction, a self-healing oxide film is formed to cover Na-K Liquid alloy electrodes.

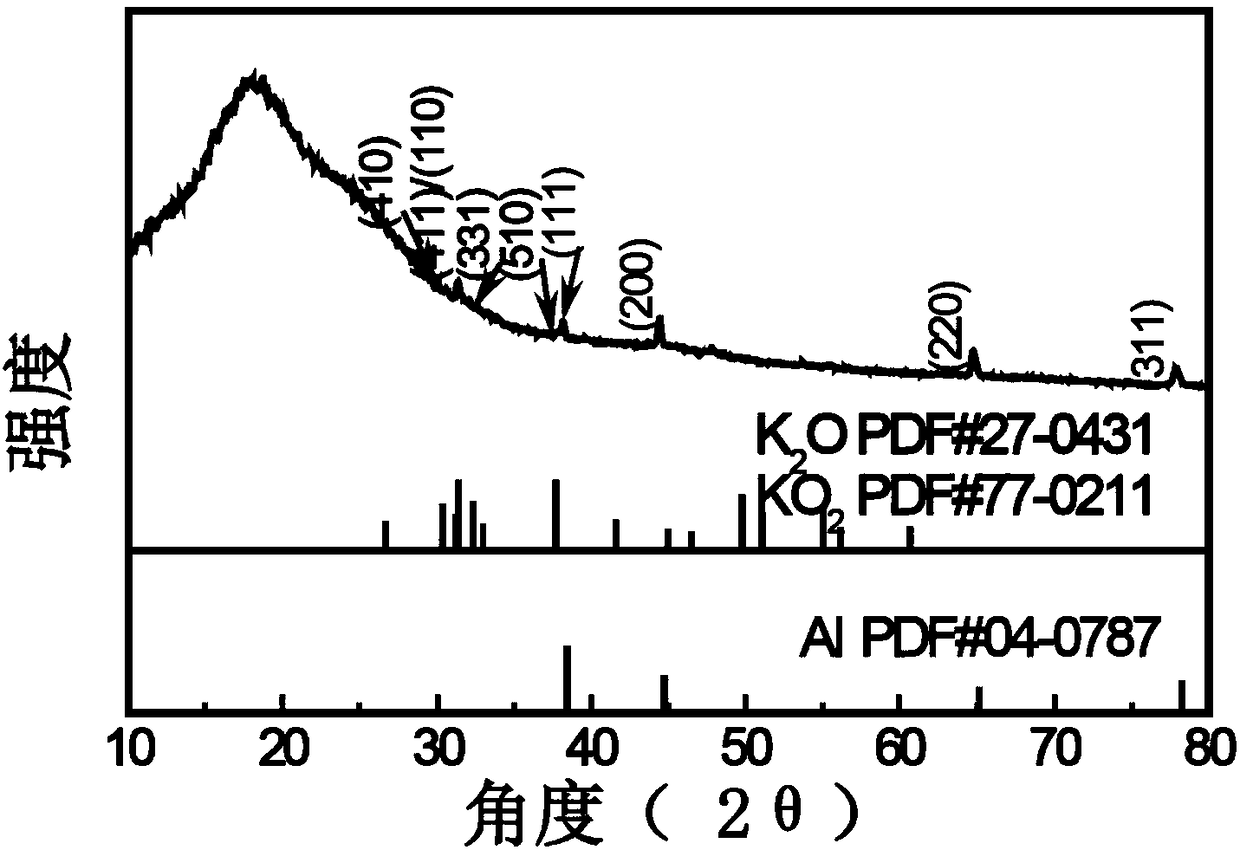

[0047] The XRD diffractogram of the self-repairing oxide film coating Na-K liquid alloy electrode surface that makes in embodiment 1 is as follows image 3 shown. As shown in the figure, the prepared electrode has no characteristic peaks of Na metal and K metal, indicating that the formed alloy is a liquid Na-K alloy. Also found weak KO 2 and K 2 The peak of O indicates t...

Embodiment 2

[0049] Adjust the oxygen content in the glove box to 0.2ppm, and the nitrogen content to 0.1ppm. Heat 0.2g of K metal and 0.056g of Na metal in a glove box to 400°C to melt respectively, and then use tweezers to contact the two kinds of molten metal with a carbon cloth (thickness 2mm) of 1cm in length and width. Cool to room temperature 25°C. Stack the carbon cloth loaded with K metal and Na metal respectively, and the alloying reaction of the two metals occurs on the surface of the carbon cloth, and a self-healing oxide film is formed on the surface. After a period of reaction, a self-healing oxide film is formed to cover Na-K Liquid alloy electrodes.

[0050] The XRD diffraction pattern that obtains electrode is similar to embodiment 1, finds in addition a small amount of KN 3 peak.

Embodiment 3

[0052] Heat 0.2g of K metal and 0.056g of Na metal in a glove box to 400°C to melt respectively, and then use tweezers to contact the two kinds of molten metal with a carbon cloth (thickness 2mm) of 1cm in length and width. Cool to room temperature 25°C. Immerse the carbon cloth loaded with K metal and Na metal respectively in the electrolyte (the solute is KPF with a molar ratio of 1:1 6 and NaPF 6 ; The organic solvent is a solution composed of ethylene carbonate (EC) and dimethyl carbonate (DMC) at a volume ratio of 1:1, KPF 6 and NaPF 6 The concentration in the electrolyte is 1mol / L), and stacked, the alloying reaction of the two metals occurs on the surface of the carbon cloth, and a self-repairing oxide film with new components is formed on the surface. After a period of reaction, a self-repairing oxide film is formed. The oxide film covers the Na-K liquid alloy electrode.

[0053] The obtained XRD diffraction pattern of the electrode is similar to that of Example 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com