A kind of high-nickel ternary positive electrode material with twice surface modification and preparation method thereof

A positive electrode material and subsurface technology, applied in the field of high-nickel ternary positive electrode materials and its preparation, can solve the problems of lower thermal decomposition temperature, large amount of desorption, and low thermal stability of materials, and achieve long cycle life and broad application prospects , the effect of high specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of a high-nickel ternary positive electrode material modified twice, comprising the following steps:

[0033] Step 1, the soluble salt of cobalt sulfate, nickel sulfate and manganese sulfate or A is made into solution S;

[0034] Step 2. Add the precipitating agent and the chelating agent into the stirring solution S, adjust the solution temperature to 30-70°C, and the pH to 10.0-12.0 to precipitate the high-nickel precursor P1;

[0035] Step 3: Wash the high-nickel precursor P1 to remove residual ions, dry it in an environment of 100-350°C and set it aside;

[0036] Step 4: Mix the high-nickel precursor P1 with the precursor P2 and lithium hydroxide, put it into a sagger, oxidize it under oxygen at 700-800°C for 5-20 hours, and obtain the first-calcined product C1 after crushing;

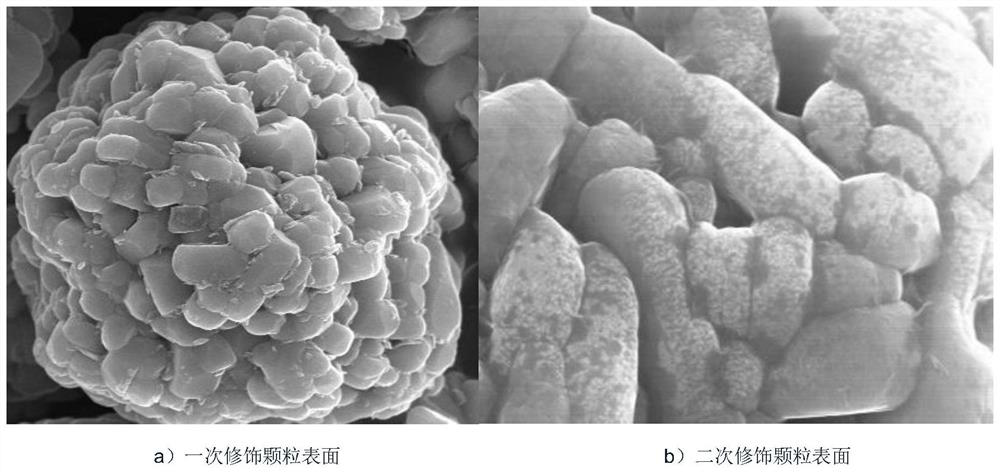

[0037] Step 5: Add the one-calcined product C1 into the reaction kettle, pass through the pre-prepared citric acid-methanol-ethanol solution, stir continuously for 0.5-...

Embodiment 1

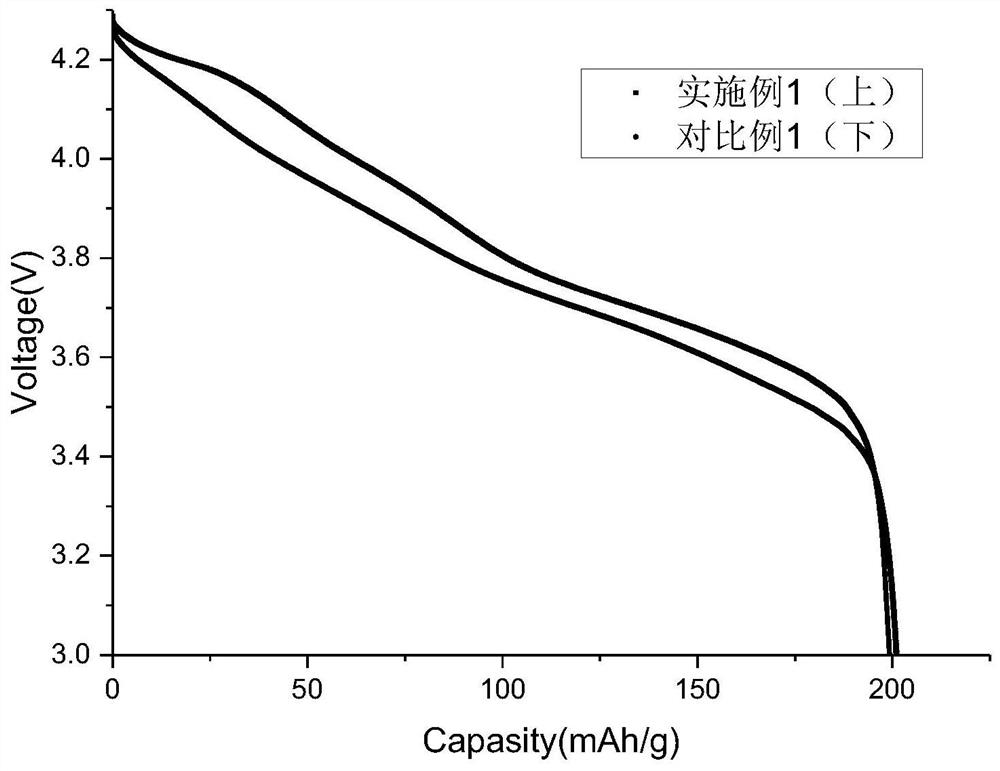

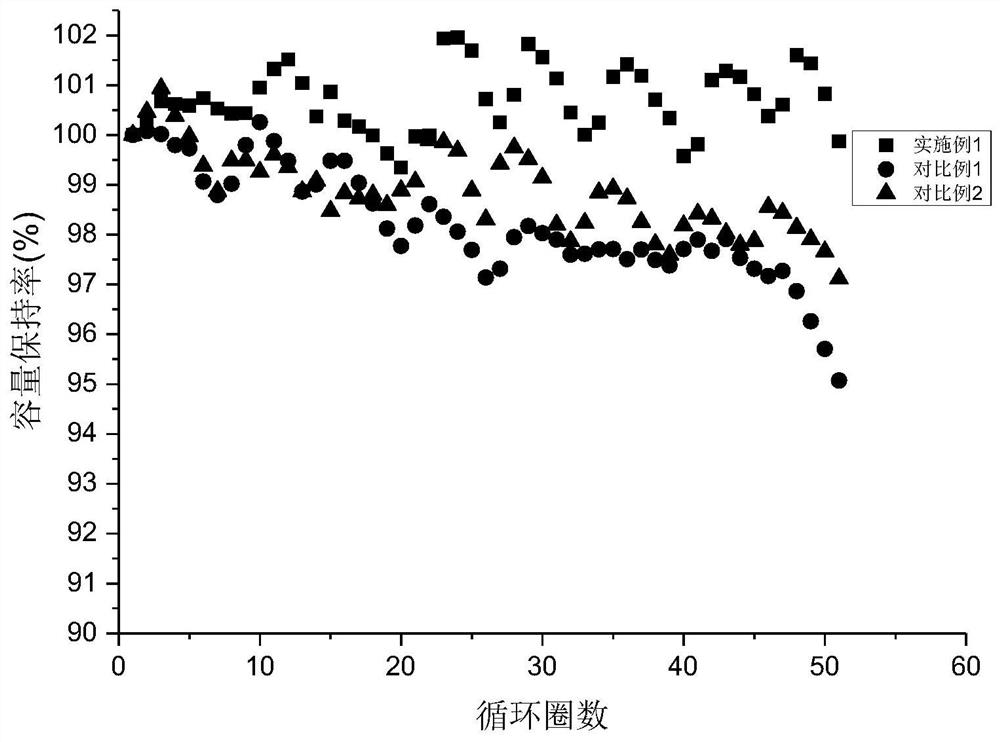

[0048] Firstly, nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate are made into a solution according to the elemental molar ratio Ni0.82Co0.14Mn0.01Al0.03. Under vigorous stirring, the solution temperature is 50°C and the speed is 700r / min; add hydroxide Sodium solution and ammonia water, adjust the pH to 11.5±0.05, and precipitate the precursor; the precursor is washed and dried, and mixed with Co3O4 and lithium hydroxide with a particle size D50 of 150 nanometers. The amount of Co3O4 added is 0.5% of the mass of the precursor. The Li / me ratio is 1.03. After the mixing is completed, put it into a sagger, and carry out high-temperature sintering in an oxygen atmosphere at 765°C for 10 hours in a high-temperature roller kiln or an experimental box-type furnace to obtain a first-fired powder; the obtained powder is added to a stirred tank , into the pre-prepared citric acid-methanol-ethanol solution, stirred for 20 minutes, vacuum-dried for 3 hours after suct...

Embodiment 2

[0052] In this embodiment, the similarities with Embodiment 1 will not be repeated, and the difference is: the design ratio is Ni0.58Co0.195Mn0.195Mg0.03. The primary sintering temperature is 850°C. The secondary sintering temperature is 400°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com