VOC biological breathable purifier and purifying method

A technology of biological purification and purifier, which is applied in the direction of chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems that the technology is difficult to meet the work requirements, the air purification effect is not satisfactory, and the degree of automation is low, so as to save labor costs, The effect of convenient management and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

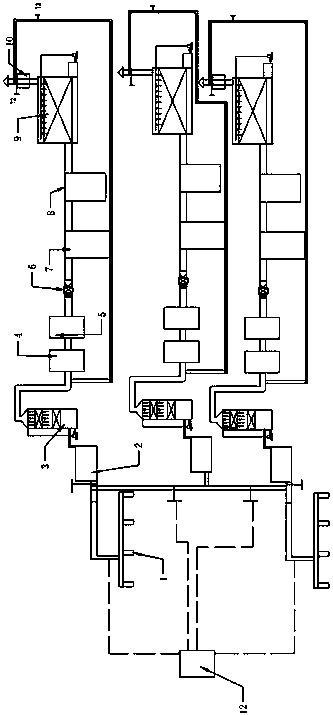

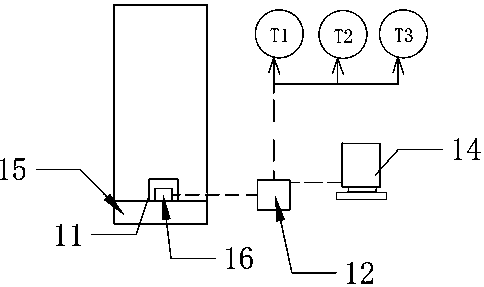

[0043] A kind of VOC biological breathable purifier, see Figure 1 to Figure 8 , including at least 3 sets of purification lines, at least 1 set of backup purification lines and a control mechanism for controlling the opening and closing of each assembly line, the control mechanism includes a control valve installed on each line and a controller 12 electrically connected to the control valve circuit; the backup purification The design of the assembly line makes it possible to stop the line and improve production efficiency when a certain assembly line fails.

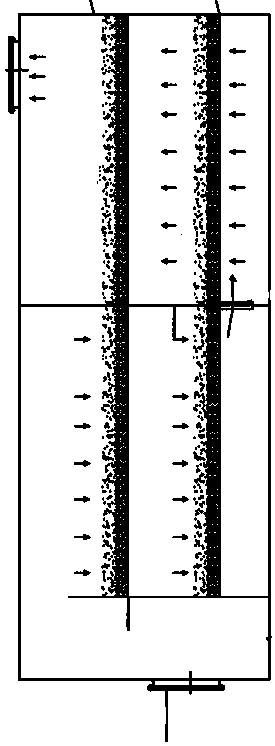

[0044] The above-mentioned assembly line includes a spray device, a centrifugal fan 6, and a biological purification device connected in sequence by the main gas pipeline. The spray purification device includes a spray circulation pool 2 and a spray scrubber 3. The biological purification device includes a biological strain cultivation tank 7. Biological processor 8, high-efficiency biological purification tower 9, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com